Heat straightening is a process used to restore the shape and integrity of metal components that have been distorted due to bending, twisting, or other forms of deformation. The process involves heating the metal to a specified temperature and then cooling it in a controlled manner. The temperature, cooling rate, and other parameters are carefully controlled to allow the metal to regain its original shape and strength.

The process is commonly used in the construction, transportation, and manufacturing industries to repair damaged components, such as beams, bridges, and vehicles, as well as to correct manufacturing defects. It can be used on various types of metal, including steel and aluminum, and can be performed in a workshop or on-site, depending on the size and complexity of the component.

Heat straightening is a specialized process that requires skilled technicians and specialized equipment, and it is important to follow proper procedures and guidelines to ensure that the component is returned to its original specifications and strength. In some cases, the component may require additional treatments, such as stress-relieving or annealing, to restore its full strength and integrity.

Answer:

The process can be performed on various metal types, including:

These metal types can be heat-straightened if they have been deformed due to bending, twisting, or other forms of distortion. The suitability of a metal type may depend on several factors, including its size, shape, thickness, and chemical composition.

Larger and thicker components, such as beams and channels, may require more specialized equipment and techniques for heat straightening, whereas smaller and thinner components, such as sheets and angles, may be more easily heat-straightened.

It’s always best to consult a metals service center for specific recommendations and guidelines regarding heat straightening of metal components.

Answer:

Most grades of carbon steel can be heat straightened. However, the specific grades that are suitable depend on the intended application and the desired outcome.

Low carbon steels, such as 1018 and 1020, are typically more easily heat-straightened due to their low carbon content, which allows them to be more readily deformable. Medium carbon steels, such as 1045 and 1060, are also heat-straightenable, but may require higher temperatures and more specialized equipment due to their higher carbon content.

High carbon steels, such as 1095 and 4140, are less commonly heat-straightened due to their high carbon content, which makes them more difficult to deform and can result in cracking if not properly heat-treated. However, under certain conditions and with proper heat treatment, these high carbon steels can be heat-straightened, but it is typically a more specialized process that requires more advanced equipment and expertise.

It’s important to note that the specific grades of carbon steel that are suitable for heat straightening can vary depending on the specific application, the intended use of the component, and the desired outcome. It’s always best to consult a metals service center for specific recommendations and guidelines.

Answer:

Heat straightening typically involves the following steps:

The process can be performed on a wide range of metal components, including bars, plates, sheets, angles, beams, channels, pipes, and tubes. The specific appearance of a heat straightening process will depend on the size and type of metal being straightened, the desired outcome, and the specific conditions of the heat straightening process. In general, heat straightening is a fast and effective method for repairing damaged metal components and restoring them to their original shape and strength.

What metal types—bar, plate, sheet, angles, beams, channels, pipes, tubes—are heat straightened?

Answer:

The process can be performed on various metal types, including:

These metal types can be heat-straightened if they have been deformed due to bending, twisting, or other forms of distortion. The suitability of a metal type may depend on several factors, including its size, shape, thickness, and chemical composition.

Larger and thicker components, such as beams and channels, may require more specialized equipment and techniques for heat straightening, whereas smaller and thinner components, such as sheets and angles, may be more easily heat-straightened.

It’s always best to consult a metals service center for specific recommendations and guidelines regarding heat straightening of metal components.

Which grades of carbon steel can be heat straightened?

Answer:

Most grades of carbon steel can be heat straightened. However, the specific grades that are suitable depend on the intended application and the desired outcome.

Low carbon steels, such as 1018 and 1020, are typically more easily heat-straightened due to their low carbon content, which allows them to be more readily deformable. Medium carbon steels, such as 1045 and 1060, are also heat-straightenable, but may require higher temperatures and more specialized equipment due to their higher carbon content.

High carbon steels, such as 1095 and 4140, are less commonly heat-straightened due to their high carbon content, which makes them more difficult to deform and can result in cracking if not properly heat-treated. However, under certain conditions and with proper heat treatment, these high carbon steels can be heat-straightened, but it is typically a more specialized process that requires more advanced equipment and expertise.

It’s important to note that the specific grades of carbon steel that are suitable for heat straightening can vary depending on the specific application, the intended use of the component, and the desired outcome. It’s always best to consult a metals service center for specific recommendations and guidelines.

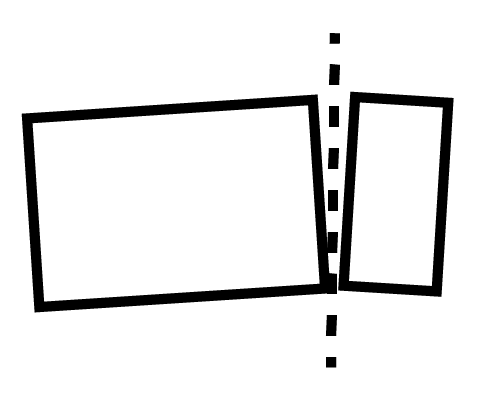

What does heat straightening look like?

Answer:

Heat straightening typically involves the following steps:

The process can be performed on a wide range of metal components, including bars, plates, sheets, angles, beams, channels, pipes, and tubes. The specific appearance of a heat straightening process will depend on the size and type of metal being straightened, the desired outcome, and the specific conditions of the heat straightening process. In general, heat straightening is a fast and effective method for repairing damaged metal components and restoring them to their original shape and strength.

It’s time to celebrate one of our veteran branches, located just outside of...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: