Kloeckner Metals offers structural angles and bar angles in various dimensions and grades across our network of nationwide branches.

| Grades | Size Ranges | |||

|---|---|---|---|---|

| A36 | 3" x 2" x 3/16" - 8" x 8" x 1-1/8" | |||

| ASTM A529-50 | 3" x 2" x 3/16" - 8" x 8" x 1-1/8" | |||

| Grades | Size Ranges | |||

|---|---|---|---|---|

| A36 | 3/4" x 3/4" x 1/8" - 2-1/2" x 2-1/2" x 1/2" | |||

| ASTM A529-50 | 3/4" x 3/4" x 1/8" - 2-1/2" x 2-1/2" x 1/2" | |||

| ASTM A572-50 | 3/4" x 3/4" x 1/8" - 2-1/2" x 2-1/2" x 1/2" | |||

This product grade is the most widely used. Due to great weldability, machinability, formability, and affordability, A36 works well for most construction and industrial applications. It has a max carbon content of 2.6% and can be galvanized to increase corrosion resistance.

This steel grade offers greater strength to weight ratio than A36 steel, and is almost exclusively used for structural applications. It has a minimum yield point of 50 ksi. The addition of copper is another main difference between A36 grade structural steel angle and A529. It’s extra .2% of copper content better protects it from corrosion.

This is a high strength low alloy (HSLA) structural steel product. It benefits from the addition of columbium-vanadium resulting in increased tensile strength. This grade is widely seen in the transportation industry.

This product grade is the most widely used. Due to great weldability, machinability, formability, and affordability, A36 works well for most construction and industrial applications. It has a max carbon content of 2.6% and can be galvanized to increase corrosion resistance.

This steel grade offers greater strength to weight ratio than A36 steel, and is almost exclusively used for structural applications. It has a minimum yield point of 50 ksi. The addition of copper is another main difference between A36 grade structural steel angle and A529. It’s extra .2% of copper content better protects it from corrosion.

This is a high strength low alloy (HSLA) structural steel product. It benefits from the addition of columbium-vanadium resulting in increased tensile strength. This grade is widely seen in the transportation industry.

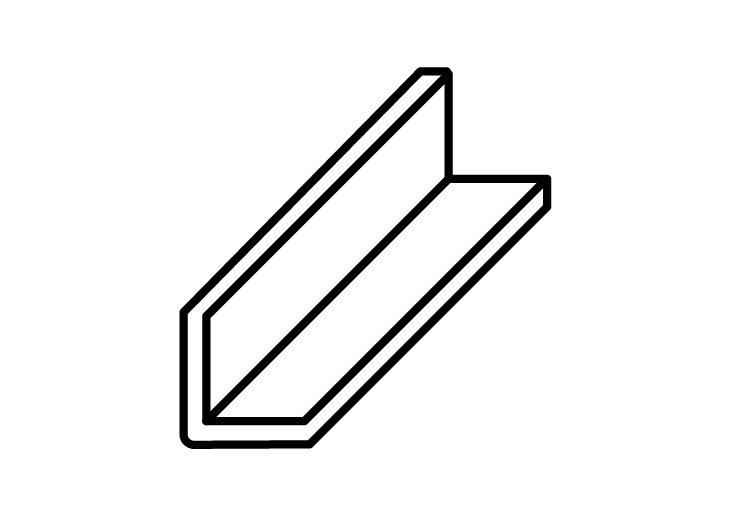

A structural angle is a widely used structural steel product. It can be used for building communication towers, bridges, coffee tables, and more. All angles are formed by two legs that are attached to a vertical web, forming an L-shaped cross section. Legs can be of equal or unequal lengths and angles are usually 90 degrees, but can be sized to customer specification to satisfy a range of project requirements.

Angles are made from hot rolled steel and are available as steel angles and bar angles. Steel angles will have legs greater than 3″, and bar angles are smaller. Both are commonly used in structural and general fabrication applications across a wide range of industries, including architectural and construction. However, bar angles are specifically common in masonry and are often attached to different surfaces and held together either by welding or drilling.

ANSWER:

Bar angles are often sized 1/2″ x 1/2″ x 1/8″ up to 2-1/2″. The steel angles are larger, and are commonly stocked from 3″ x 2″ x 3/16″ and up.

ANSWER:

Steel angle dimensions are determined by the width, length, and thickness. Steel angles have legs that are greater than 3 inches and bar angles will be smaller. They can be cut to any length.

ANSWER:

Typical steel angles properties include a minimum yield strength of 50 ksi, good machinability, formability, and weldability.

ANSWER:

Bar angles are often sized 1/2″ x 1/2″ x 1/8″ up to 2-1/2″. The steel angles are larger, and are commonly stocked from 3″ x 2″ x 3/16″ and up.

ANSWER:

Steel angle dimensions are determined by the width, length, and thickness. Steel angles have legs that are greater than 3 inches and bar angles will be smaller. They can be cut to any length.

ANSWER:

Typical steel angles properties include a minimum yield strength of 50 ksi, good machinability, formability, and weldability.

Between our global footprint, international transportation network,...

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: