Kloeckner Metals sells 6061 and 6063 aluminum channel. Contact us today to get a quote.

| Grades | Tempers | |||

|---|---|---|---|---|

| 6061 | T6 | T6511 | |||

| 6063 | T5 | T6 | T6511 | |||

6061 is a high strength multipurpose heat treatable aluminum perfect for extrusion. It is fabricated for countless applications ranging from aircraft and aerospace equipment to automotive parts, pipe fittings, and structural framing.

This aluminum grade stands apart for forming capability and is considered the easiest 6000 series alloy for extrusion. Some tradeoffs include poorer strength but excellent corrosion resistance and surface finishing. It can be anodized to further enhance resistance to rust and weathering. It is primarily used for exterior railings, decorative trim, masonry mounts, and door frames.

6061 is a high strength multipurpose heat treatable aluminum perfect for extrusion. It is fabricated for countless applications ranging from aircraft and aerospace equipment to automotive parts, pipe fittings, and structural framing.

This aluminum grade stands apart for forming capability and is considered the easiest 6000 series alloy for extrusion. Some tradeoffs include poorer strength but excellent corrosion resistance and surface finishing. It can be anodized to further enhance resistance to rust and weathering. It is primarily used for exterior railings, decorative trim, masonry mounts, and door frames.

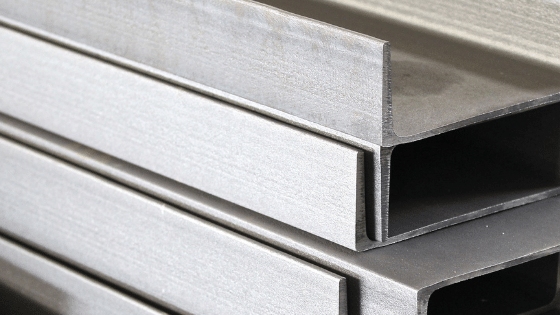

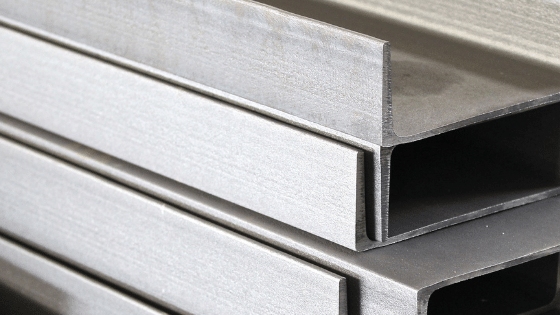

Aluminum channels are a particular aluminum extrusion product. They can be made either by cold or hot extrusion, depending on the alloy composition and have a wide variety of uses, from structural to decorative. They are used for various structural applications in construction and can have more decorative applications in the architecture industry. They are found in automotive parts (chassis, doors, trunk), aircraft and aerospace equipment, trains, and ships as well.

ANSWER:

They are a type of aluminum extrusion product, made either by the cold or hot extrusion process, depending on the alloy composition. Common channel shapes include the C/U channel, hat/furring channel, and strut channels.

ANSWER:

Typically, channels resemble a C or U shape, with equal length flanges. The flanges can be either parallel (straight) or they can be tapered (rounded edge points).

Hat channels are also available, and differ in both shape and application. Hat channels are as described above for C/U channels with an additional flat top flange on either side. They are also called furring channels and are most commonly used for masonry to level out walls.

Strut channels look like the C channels but have holes along the length. These are standard channels for structural forming in the electrical and structural industries that serve to support mechanical components, or wiring.

ANSWER:

6061 and 6063 are the two most popular grades for channels. They are the easiest extrusion alloys and differ mainly in strength. Generally, 6061 aluminum is a stronger alloy and is better suited for load bearing uses while 6063 shows excellent surface finishing and poorer strength, making it more suitable where appearance is a critical factor.

ANSWER:

They are a type of aluminum extrusion product, made either by the cold or hot extrusion process, depending on the alloy composition. Common channel shapes include the C/U channel, hat/furring channel, and strut channels.

ANSWER:

Typically, channels resemble a C or U shape, with equal length flanges. The flanges can be either parallel (straight) or they can be tapered (rounded edge points).

Hat channels are also available, and differ in both shape and application. Hat channels are as described above for C/U channels with an additional flat top flange on either side. They are also called furring channels and are most commonly used for masonry to level out walls.

Strut channels look like the C channels but have holes along the length. These are standard channels for structural forming in the electrical and structural industries that serve to support mechanical components, or wiring.

ANSWER:

6061 and 6063 are the two most popular grades for channels. They are the easiest extrusion alloys and differ mainly in strength. Generally, 6061 aluminum is a stronger alloy and is better suited for load bearing uses while 6063 shows excellent surface finishing and poorer strength, making it more suitable where appearance is a critical factor.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: