It’s time to celebrate one of our veteran branches, located just outside of the hustle and bustle of Atlanta, Georgia. We have three branches strategically placed a few miles down the street from the iconic home of the Braves, but today, we want to celebrate the company culture and share the current wins coming from our Suwanee metal supplier.

This facility is unmistakably Kloeckner territory. The biggest reason is that the leadership at this branch is committed to our Family First and Safety Always culture. Regional GM Tommy Campbell holds quarterly all-hands meetings to discuss industry trends and company-wide wins. The open dialogue encourages transparency and helps support business operations, but this team also gathers for meals and meet-ups off the clock.

Campbell started at Kloeckner as an Operations Manager in 2014, and during his tenure, he’s been involved with eight branches in the Southeast area. When speaking about the work at Suwanee, he stated, “We put the ‘service’ in ‘service center’ at this branch.” He continued, “and that’s not just for our commercial teams or customers; the second shift treats the first shift as their customer and so on. They are committed to getting the job done because they realize any slack in the line means more work for the next crew.”

Suwanee just celebrated a safety milestone of going two years without an LTA, and we have a feeling that it’s that strong sense of family behind it. Under Campbell’s watch, this team exceeds Top Dog safety KPIs, but more importantly, he makes sure they understand the value of learning from genuine close calls, so everyone goes home safe.

Suwanee has two dedicated CAD Programmers lending their talents to the daily demand of all their unique orders. Each shift has highly skilled equipment operators to perform various value-added services, such as thermal plate/sheet cutting, etching, forming, punching, sawing, drilling, milling, profiling, cambering, splitting, and heat straightening.

Sales Manager, Jon Crum, speaks about the team with passion, “We’ve got an extremely seasoned and experienced team that is in tune with our market. He put a finer point on it, “The veteran knowledge and their influence in educating new generations allows us to capitalize on our in-house processing capabilities today and sets us up for greater success tomorrow.”

This ISO modeled quality management branch offers many long products stocked in several grades and lengths. Their portfolio includes work on beams, channels, angles, bars, pipes, mechanical/structural tubes, plates, sheets, grating, and flooring products.

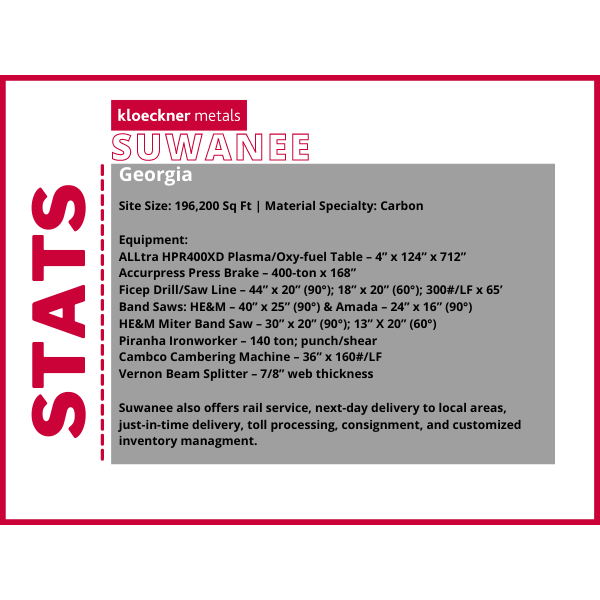

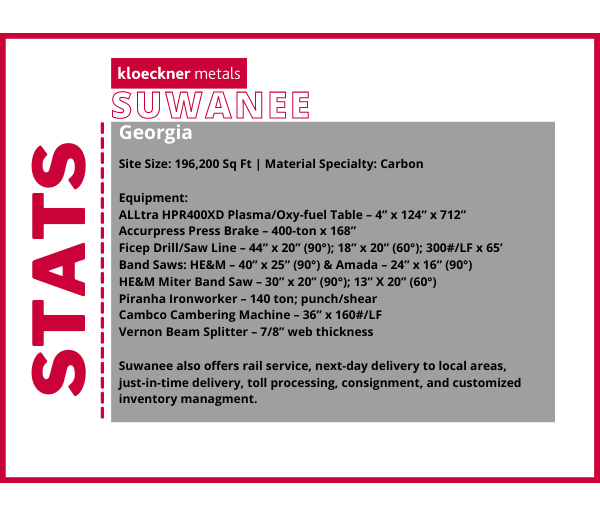

The facility houses several different types of robust equipment to ensure they can exceed expectations with all their value-added requests. Here’s a look at the machine power under their roof:

They’re also equipped with ten overhead cranes and one Gantry crane with a 15-ton max capacity.

We’re honored to have each and every member of our Suwanee branch helping set the tone for all others. Way to put your best boot forward and keep our customers coming back!

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: