Kloeckner Metals offers beveling services throughout its North American branches. Learn more about beveling and its importance to the metals industry.

Beveling is a process commonly used in the manufacturing industry to create a sloped or angled edge on a workpiece, typically metal, in order to facilitate joining or welding operations. The purpose of beveling is to provide a smooth transition between two surfaces, ensuring better fit and weld quality.

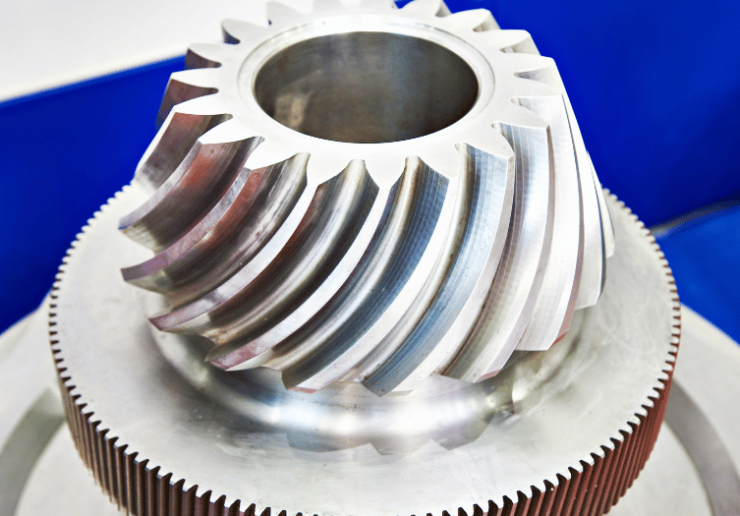

Beveling can be accomplished using various methods, including beveling, flame cutting, and plasma cutting machines. Machine beveling involves the use of specialized equipment such as milling machines, grinders, or beveling machines that cut or grind the edge of the material to the desired angle. This method offers precise control and consistency in creating beveled edges.

Flame cutting, also known as oxy-fuel cutting, employs the use of an oxygen-fuel torch to heat the workpiece and then uses a stream of oxygen to blow away the molten metal. By manipulating the torch, operators can create beveled edges of different angles.

Plasma cutting, on the other hand, utilizes a high-velocity jet of ionized gas, or plasma, to melt and remove the metal. The plasma arc can be directed to create beveled edges by tilting the cutting head at an angle.

Overall, beveling is an essential process in manufacturing industries as it helps enhance the quality and integrity of weld joints by ensuring proper fit-up and welding penetration, and it can be achieved through machine-based methods like milling or grinding, as well as through thermal methods like flame cutting and plasma cutting. Kloeckner Metals is proud to offer beveling at multiple branches across North America.

Answer:

It is a metalworking process in which the edge of a piece of metal is angled or sloped, typically at a 45-degree angle. This process is commonly used in the welding industry to prepare two pieces of metal for joining, as it creates a clean, smooth edge that is easy to fuse together. It can be done manually using a hand tool or with a specialized machine called a beveling machine. The process can be applied on all types of metal, including steel and aluminum.

Answer:

Plasma cutting is a process that uses a high-velocity stream of ionized gas to cut through metal. It is a common method for cutting metal sheets and plates, but it is not typically used for beveling.

Beveling is typically done using a specialized machine called a beveling machine which uses a rotating cutting tool to create the angled edge. However, plasma cutting can be used to make the initial rough cut on a metal piece before beveling, this would allow for a more precise process, as the initial rough cut is already done.

It’s also possible to use plasma bevel cutting, which is a combination of the two processes. This process uses a specialized torch that can cut and bevel at the same time, this is a faster and more efficient process for doing both cuts at once.

Answer:

It is commonly used in a wide range of industries, including:

What is beveling?

Answer:

It is a metalworking process in which the edge of a piece of metal is angled or sloped, typically at a 45-degree angle. This process is commonly used in the welding industry to prepare two pieces of metal for joining, as it creates a clean, smooth edge that is easy to fuse together. It can be done manually using a hand tool or with a specialized machine called a beveling machine. The process can be applied on all types of metal, including steel and aluminum.

Is plasma cutting used in beveling?

Answer:

Plasma cutting is a process that uses a high-velocity stream of ionized gas to cut through metal. It is a common method for cutting metal sheets and plates, but it is not typically used for beveling.

Beveling is typically done using a specialized machine called a beveling machine which uses a rotating cutting tool to create the angled edge. However, plasma cutting can be used to make the initial rough cut on a metal piece before beveling, this would allow for a more precise process, as the initial rough cut is already done.

It’s also possible to use plasma bevel cutting, which is a combination of the two processes. This process uses a specialized torch that can cut and bevel at the same time, this is a faster and more efficient process for doing both cuts at once.

Which industries rely on beveling?

Answer:

It is commonly used in a wide range of industries, including:

Welding aluminum makes countless products possible. Like auto pistons, aircraft, marine valves, bikes,...

Today’s branch spotlight takes us to the land of deep dish pizza, full...

The Kloeckner Metals Tampa location has been servicing the Central Florida area for...

The Haas VF-8 is able to do beveling work and it can also...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: