Kloeckner Metals stocks 316L stainless steel bar, a stainless steel product often used in applications exposed to chemical corrodents.

Showcasing some of the best corrosion resistance within the stainless steel family, this stainless steel grade can be conveniently welded and is highly ductile and formable. Like all austenitic steels, it cannot be hardened by heat treatment and is not magnetic.

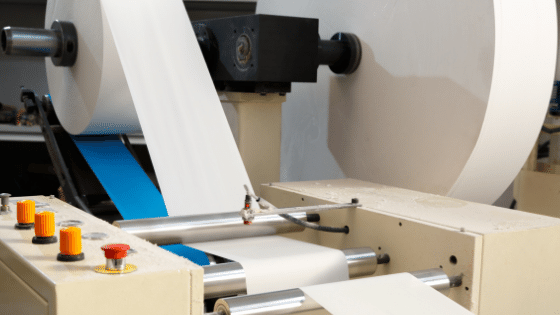

This product can be found in various industries, particularly those industries dealing with highly corrosive environments and exposure to marine atmospheres. This includes the food and dairy, brewing, textile, pulp and paper, chemical processing, and pharmaceutical industries among others.

Digesters, chemical, paper, and textile processing equipment and applications where corrosion resistance is critical are common applications for this stainless steel grade.

It is machinable.

It is weldable.

It is not heat treatable.

Showcasing some of the best corrosion resistance within the stainless steel family, this stainless steel grade can be conveniently welded and is highly ductile and formable. Like all austenitic steels, it cannot be hardened by heat treatment and is not magnetic.

This product can be found in various industries, particularly those industries dealing with highly corrosive environments and exposure to marine atmospheres. This includes the food and dairy, brewing, textile, pulp and paper, chemical processing, and pharmaceutical industries among others.

Digesters, chemical, paper, and textile processing equipment and applications where corrosion resistance is critical are common applications for this stainless steel grade.

It is machinable.

It is weldable.

It is not heat treatable.

316L stainless steel bar is one of the most corrosion resistant austenitic stainless steels. Molybdenum protects the stainless steel in corrosive environments. Chemical processing equipment, textile processing equipment, paper and pulp processing equipment, and heat exchangers are all good candidates for 316L stainless steel bar because of their regular exposure to corrosive environments.

ANSWER:

The manufacturing processes differ between bar and tube. Usually only tubes are welded when formed. This can lead to more homogenous strength and consistency in hollow bar.

ANSWER:

Yes. It performs particularly well in marine atmospheres due to its corrosion resistant nature.

ANSWER:

The manufacturing processes differ between bar and tube. Usually only tubes are welded when formed. This can lead to more homogenous strength and consistency in hollow bar.

ANSWER:

Yes. It performs particularly well in marine atmospheres due to its corrosion resistant nature.

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: