316L stainless steel tube is a stainless steel product often used in applications with exposure to highly corrosive environments. Kloeckner Metals is proud to supply it nationwide throughout our network of 40+ branches.

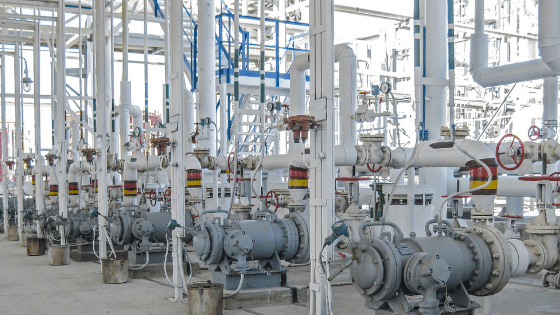

316L stainless steel tube is a highly corrosion resistant chromium nickel austenitic stainless steel. Due to the addition of molybdenum, it is protected in corrosive environments and can be used in chemical processing equipment common in the textiles, paper and pulp, and industry, as well as for heat exchangers and other parts exposed to marine atmospheres.

This stainless steel grade can be more easily welded than comparable stainless steels. It is highly ductile and conveniently formed. However, as with all austenitic steel grades, it cannot be hardened by heat treatment and is not magnetic.

It is frequently found in industries dealing with corrodent exposure like marine environments. This includes the food and dairy, brewing, textile, pulp and paper, chemical processing, pharmaceutical, and biotech industries.

Storage tanks, shipping vessels and valves, digesters, chemical, paper, and textile processing equipment as well as applications exposed to elevated temperatures and where corrosion resistance is a critical factor are common applications for this stainless steel grade.

It is machinable.

It is weldable. Molybdenum makes this stainless steel product easier to weld than other austenitic stainless steels and weldments are less likely to experience intergranular corrosion, pitting, creep, and cracking.

It is not heat treatable.

This stainless steel grade can be more easily welded than comparable stainless steels. It is highly ductile and conveniently formed. However, as with all austenitic steel grades, it cannot be hardened by heat treatment and is not magnetic.

It is frequently found in industries dealing with corrodent exposure like marine environments. This includes the food and dairy, brewing, textile, pulp and paper, chemical processing, pharmaceutical, and biotech industries.

Storage tanks, shipping vessels and valves, digesters, chemical, paper, and textile processing equipment as well as applications exposed to elevated temperatures and where corrosion resistance is a critical factor are common applications for this stainless steel grade.

It is machinable.

It is weldable. Molybdenum makes this stainless steel product easier to weld than other austenitic stainless steels and weldments are less likely to experience intergranular corrosion, pitting, creep, and cracking.

It is not heat treatable.

ANSWER:

It’s easy to confuse 316 and 316L stainless steels, however a few key differences make 316L a more sought after stainless steel product. For one, the L indicates that this grade is the ultra low carbon variant. In this case, what is primarily a chromium and nickel based stainless product, the 316L variant also includes the addition of molybdenum, which is what gives this grade a particular advantage when it comes to highly corrosive environments.

ANSWER:

It is available in 2B #3 and #4 polish.

ANSWER:

It’s easy to confuse 316 and 316L stainless steels, however a few key differences make 316L a more sought after stainless steel product. For one, the L indicates that this grade is the ultra low carbon variant. In this case, what is primarily a chromium and nickel based stainless product, the 316L variant also includes the addition of molybdenum, which is what gives this grade a particular advantage when it comes to highly corrosive environments.

ANSWER:

It is available in 2B #3 and #4 polish.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: