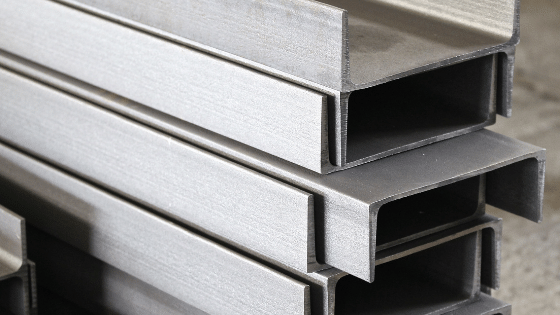

Kloeckner Metals supplies structural channels, MC channels, and bar channels in various grades and dimensions. Channels can be cut to customer specifications.

| Grades | Size Ranges | |||

|---|---|---|---|---|

| A36 | 3" x 3.5# - 15" x 50.0# | |||

| ASTM A529-50 | 3" x 3.5# - 15" x 50.0# | |||

| ASTM A572-50 | 3" x 3.5# - 15" x 50.0# | |||

| Grades | Size Range | |||

|---|---|---|---|---|

| A36 | 3" x 7.1# - 18" x 58.0# | |||

| ASTM A529-50 | 3" x 7.1# - 18" x 58.0# | |||

| ASTM A572-50 | 3" x 7.1# - 18" x 58.0# | |||

| Grades | Size Range | |||

|---|---|---|---|---|

| ASTM A-36 | 1" x 1/2" x 1/8" - 2-1/2" x 5/8" x 3/16" | |||

Channels are a structural steel product very common in building construction. Channels have a C shaped cross section and American standard channels have tapered legs. MC channels have squared corners, where the legs attach to the flat-backed web. Bar channels are differentiated from both channels and MC channels by their smallness. They are available in lengths under 2 1/2″.

Channels have a strong and versatile design that makes them popular across industries. General building construction, bridge construction, metal building, and the solar industry among others, all benefit from the strength, durability, and versatility channels offer to structures.

Channels are easy to weld and form. You can learn about how channels are fabricated by reading our blog about our 52-foot Cincinnati Press Brake Machine, which forms channels up to 52-feet long.

The A36 grade structural channel is an affordable hot rolled, low carbon steel product. It offers good weldability, machinability, and ductility. It can be used extensively across industries, but is most common in building constructions for support, and as framing for equipment, trucks, and trailers.

A529-50 structural steel offers higher strength than A36 grade structural steel. It will be found in high rises, buildings, and bridges as main supports.

A572-50 structural and MC channels is best for applications requiring greater strength to weight ratios. It is a high strength steel with the number 50 in its name indicating a minimum yield strength of 50 ksi.

The A36 grade structural channel is an affordable hot rolled, low carbon steel product. It offers good weldability, machinability, and ductility. It can be used extensively across industries, but is most common in building constructions for support, and as framing for equipment, trucks, and trailers.

A529-50 structural steel offers higher strength than A36 grade structural steel. It will be found in high rises, buildings, and bridges as main supports.

A572-50 structural and MC channels is best for applications requiring greater strength to weight ratios. It is a high strength steel with the number 50 in its name indicating a minimum yield strength of 50 ksi.

ANSWER:

Channels are sometimes referred to as beams. Channel I-steel refers to a beam with an I-shaped cross section. If you imagined two C-shaped or U-shaped channels held up against each other back-to-back (web-to-web) you would create an I-beam. This is sometimes referred to as an unconventional I-beam.

ANSWER:

A channel is a type of structural steel shape. It is unique in that it has one flat back (the web) and two legs (flanges) extending out from either side to form a C- or U-shaped cross section.

ANSWER:

Steel channels are used in the solar industry to mount and secure panels. They are often hot dip galvanized to improve strength, corrosion resistance, and general surface protection.

The standard size for channels used in the solar industry are 5 x 6.7 and 6 x 8.2. Kloeckner Metals routinely stocks both of these channel sizes.

ANSWER:

Channels have a width, depth, and web thickness. You’ll see channels identified by the depth X weight per unit length.

ANSWER:

Channels with a depth less than 3″ will be considered typical for bar channels, only. Structural channels and MC channels will have a depth greater than 3″.

ANSWER:

One American standard for channel dimensions is “C 5 X 9” which means it is 5 inches deep and has a weight per unit length of 9 pounds per foot. Dimensions can be sized to customer specification.

ANSWER:

Channels are sometimes referred to as beams. Channel I-steel refers to a beam with an I-shaped cross section. If you imagined two C-shaped or U-shaped channels held up against each other back-to-back (web-to-web) you would create an I-beam. This is sometimes referred to as an unconventional I-beam.

ANSWER:

A channel is a type of structural steel shape. It is unique in that it has one flat back (the web) and two legs (flanges) extending out from either side to form a C- or U-shaped cross section.

ANSWER:

Steel channels are used in the solar industry to mount and secure panels. They are often hot dip galvanized to improve strength, corrosion resistance, and general surface protection.

The standard size for channels used in the solar industry are 5 x 6.7 and 6 x 8.2. Kloeckner Metals routinely stocks both of these channel sizes.

ANSWER:

Channels have a width, depth, and web thickness. You’ll see channels identified by the depth X weight per unit length.

ANSWER:

Channels with a depth less than 3″ will be considered typical for bar channels, only. Structural channels and MC channels will have a depth greater than 3″.

ANSWER:

One American standard for channel dimensions is “C 5 X 9” which means it is 5 inches deep and has a weight per unit length of 9 pounds per foot. Dimensions can be sized to customer specification.

Between our global footprint, international transportation network,...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: