The term “Green Steel” has been all over our industry for a while now. But if you take a closer look at the topic, you quickly realize that there is no universal definition for green steel. The term is rather used at the moment to describe steel that is produced in a CO2-reduced manner. A similar situation can be observed with certificates and labels. The first producers are having their steel certified as “green”. However, these certificates vary and are therefore difficult for customers to compare.

We have eliminated that problem by developing an universal definition that is based on customers demand, steel producer perspectives, steel production technology routes and the

GHG Protocol The GHG Protocol is the leading carbon accounting body and headed by the World Resources Institute. It closely collaborates with the Carbon Disclousure Project and the Science Based Target Initiative.

as the leading carbon accounting standard.

This ground-breaking result will help our customers build sustainable value chains and achieve their sustainability goals.

"Our categorization will bring more transparency to the green steel market for our customers. We want to lead the way and have set an ambitious target: by 2025, over 30% of our products will come from the most sustainable categories."

includes all emissions that are directly caused by the company. Examples for a steel producer are:

• Emissions at its own steel manufacturing plants

• Emissions from own company vehicles

In

emissions are recorded that result from the consumption of purchased energy. This includes:

• Emissions from purchased electricity

• Emissions from district heating and cooling for the company’s own use

Here, emissions are recorded that occur even before the company’s own entrepreneurial activity. Examples for a steel producer are:

• Purchased goods like raw materials (e.g. coke and iron) and services

• Production of fixed assets

• Transport of purchased goods to the steel producer’s facilities

comprises emissions that occur after the company’s own entrepreneurial activities. Examples for a steel producer are:

• Processing of the steel products sold

• Use of the sold steel products

• Transport of the sold steel products to distributors like Klöckner & Co

In view of climate change and the urgent need to cut

such as carbon dioxide, steel has been the subject of debate since its production is often very emissions-intensive. However, alternative production processes and other advantageous properties of steel reinforce our firm conviction:

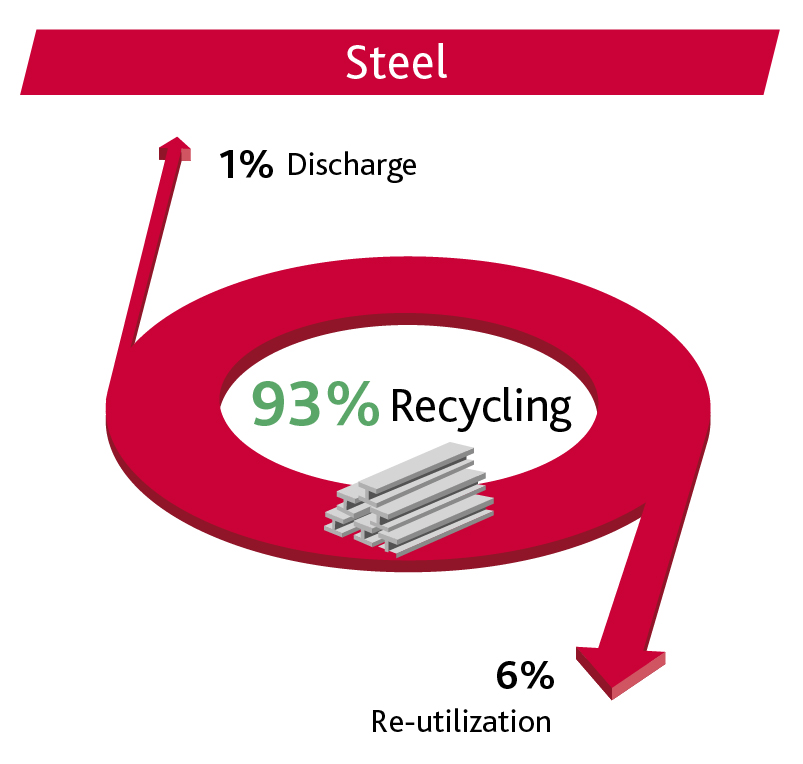

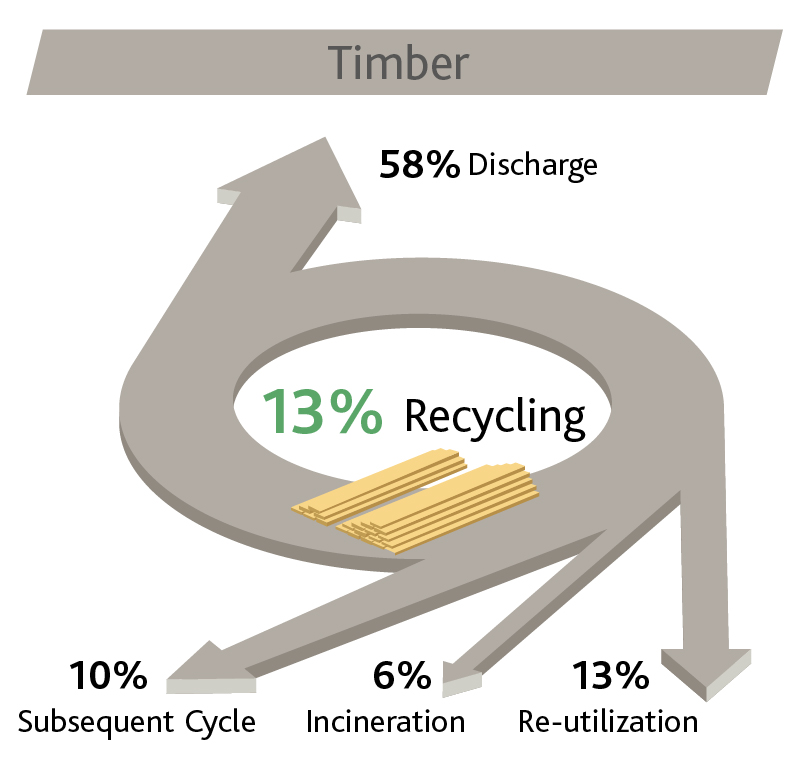

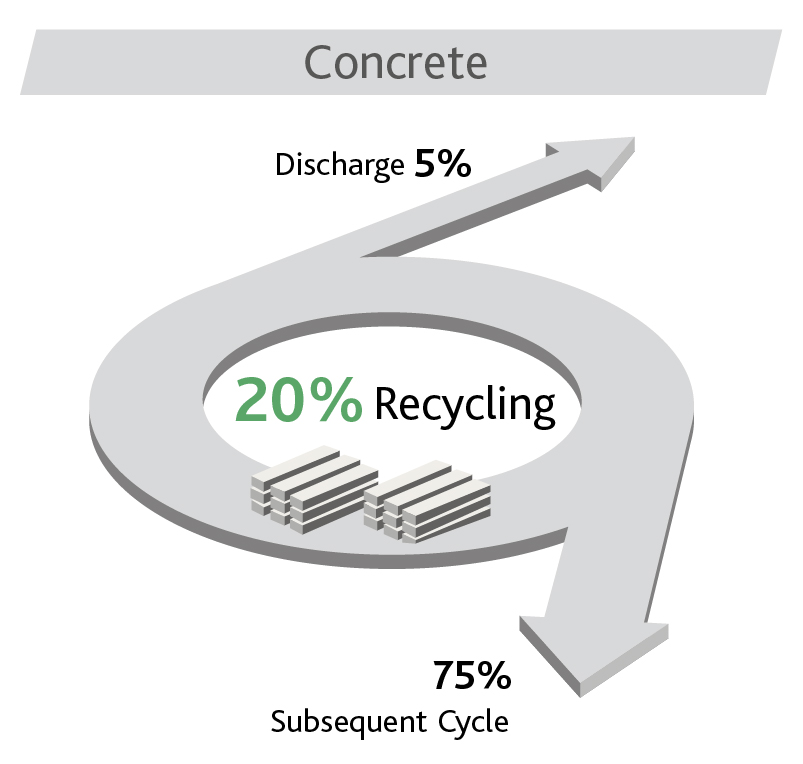

Steel is a highly sought-after material thanks to its durability and low maintenance. Compared to other materials such as concrete or timber, however, there is another major advantage that will become even more important in the future: steel can be recycled an infinite number of times without any loss of quality.

When people think of the production of steel, they usually have images of

in mind. In this energy-intensive process route, pig iron is produced in the blast furnace, which is then processed into crude steel by adding oxygen.

An alternative is the production with the

. In this method, recycled steel scrap or sponge iron produced from iron ore is melted into crude steel.

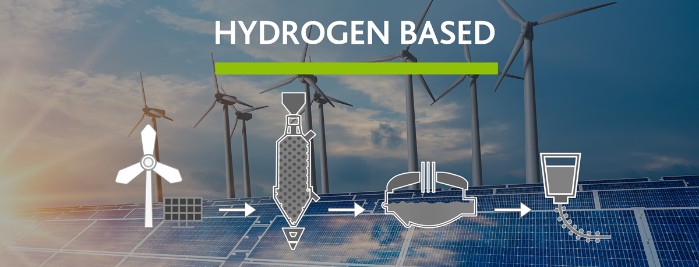

Compared to the conventional blast furnace route, an electric arc furnace produces up to 80% fewer carbon emissions. However, as emissions are still caused by this process, there is a growing desire for even more carbon-reduced steel to be produced through the use of renewable energies and green

Iron ore pellets and sinter feed are the iron-bearing raw materials. Coke from metallurgical coal is the main energy source. These elements and limestone are fed into the blast oven furnace from the top, while hot air is blasted in from the bottom. The burning coke creates temperatures of ~2000°C, extracting hot metal/pig iron from the raw material. The hot metal is transformed into steel through oxidation in a basic oxygen furnace. Often some scrap is added. The resulting liquid steel is then cast.

Most EAF mills use scrap as their main input. In regions with competitive gas prices

may also be used. For direct reduced iron, iron ore and pellets can be reduced in a solid state for use in the EAF. Natural gas is usually used as a reductant. Scrap or direct reduced iron is melted in an EAF at around 3000°C. Graphite electrodes function as an arc to transform the electrical energy into heat.

The future of steel is green. And there are two possible ways to get there. The first is steel from EAF production that uses 100% scrap and is powered with renewable energy. Given the finite amount of scrap, steel production via this route is naturally limited. The second way is using green H2 as the reductant for direct reduced iron in an electric arc furnace pathway (see electric arc furnace).

Scrap can be collected from old vehicles, steel structures, railroad tracks, ships, farm equipment and, of course, consumer scrap.

Steel needs to be separated from other scrap metals and material waste streams.

Steel is then shredded to promote the melting process, as finely shredded metals have a large surface-to-volume ratio.

Scrap is then melted in a large furnace. But melting and recycling it consumes much less energy than producing new metals using virgin raw materials.

Purification ensures that the final product is of high quality and free of contaminants.

After purification, melted steel is carried by the conveyor belt to cool and solidify. In this stage, the steel is formed into specific shapes.

Once the steel has cooled and solidified, it is ready to use and is transported to other facilities.

Through recycling, the steel industry saves enough energy to supply the annual electricity needs of more than 18 million homes.

Recycling the steel from one car reduces greenhouse gases equivalent to using more than 150 gallons of gasoline.

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: