C1020—also called 1020 steel plate—is a low carbon steel plate that is routinely stocked nationwide across our network of 40+ branches.

C1020 is also known as 1020 steel plate and is used in the turned and polished or cold drawn condition. It has a low carbon content and is therefore resistant to induction or flame hardening. It also won’t respond to nitriding due to its lack of alloying elements.

This grade has improved formability, good weldability, high strength, and high ductility. But because of its low carbon content, it is resistant to induction and flame hardening.

Some common industries are the automotive, heavy truck, and agricultural equipment industries.

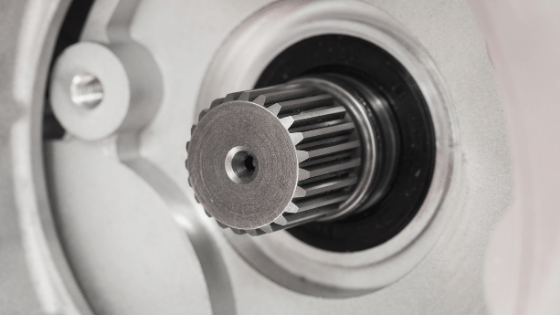

It is used in case hardened condition and often for simple structural applications. Typical applications for C1020 are axles, machinery parts, shafts, ratchets, worm gears, and spindles.

This grade steel plate has a controlled carbon range and therefore high machinability capabilities. Especially in the cold drawn and turned and polished condition, 1020 has high machinability.

The most common welding processes are used for this grade. Better weldability is caused by using cold drawn or the turned and polished condition. It is not recommended to do the welding process in heat treated or carburized condition.

C1020 steel plate is heat treatable. The order of the heat treating process include, annealing, carburizing, core refining, case hardening, tempering, normalizing and finished with stress relieving.

This grade has improved formability, good weldability, high strength, and high ductility. But because of its low carbon content, it is resistant to induction and flame hardening.

Some common industries are the automotive, heavy truck, and agricultural equipment industries.

It is used in case hardened condition and often for simple structural applications. Typical applications for C1020 are axles, machinery parts, shafts, ratchets, worm gears, and spindles.

This grade steel plate has a controlled carbon range and therefore high machinability capabilities. Especially in the cold drawn and turned and polished condition, 1020 has high machinability.

The most common welding processes are used for this grade. Better weldability is caused by using cold drawn or the turned and polished condition. It is not recommended to do the welding process in heat treated or carburized condition.

C1020 steel plate is heat treatable. The order of the heat treating process include, annealing, carburizing, core refining, case hardening, tempering, normalizing and finished with stress relieving.

1020 steel has a tensile strength of 420 MPa and a yield strength of 350 MPa. 1020’s modulus of elasticity is 205 GPa and the shear modulus is 80GPa. It has high machinability, good weldability and high ductility. 1020’s Poison’s ratio is 0.29 and the elongation at break (in 50mm) is 15%. C1020 has low hardenability properties and is a low tensile carbon steel with Brinell hardness of 121.

In ASTM standards, the equivalent steel is referred to as A108, A29 type steel.

Density: 7.87g/cc – 0.283lb/in3

1020 steel has a tensile strength of 420 MPa and a yield strength of 350 MPa. 1020’s modulus of elasticity is 205 GPa and the shear modulus is 80GPa. It has high machinability, good weldability and high ductility. 1020’s Poison’s ratio is 0.29 and the elongation at break (in 50mm) is 15%. C1020 has low hardenability properties and is a low tensile carbon steel with Brinell hardness of 121.

In ASTM standards, the equivalent steel is referred to as A108, A29 type steel.

Density: 7.87g/cc – 0.283lb/in3

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: