Kloeckner Metals sells 6061 and 6063 aluminum angle. Get in touch today for a quote.

| Grades | Tempers | |||

|---|---|---|---|---|

| 6061 | T6 | T6511 | |||

| 6063 | T5 | T6 | T6511 | |||

This high strength, general purpose aluminum is the most commonly extruded alloy. Following heat treatment its strength will match that of a low grade steel. 6061 angle is an ideal aluminum where a combination of good surface finishing, corrosion resistance, and good strength-to-weight ratio are required. The applications for this alloy are wide ranging. They include automotive and aerospace parts, sail boats and bridge components.

6063 aluminum is the optimum extrusion alloy. It demonstrates excellent surface finish and is often used for decorative trim, exterior railing, and door frames. Because this grade has a poor strength-to-weight ratio, it should not be used for critical load bearing applications. It can be anodized to increase resistance to corrosion.

This high strength, general purpose aluminum is the most commonly extruded alloy. Following heat treatment its strength will match that of a low grade steel. 6061 angle is an ideal aluminum where a combination of good surface finishing, corrosion resistance, and good strength-to-weight ratio are required. The applications for this alloy are wide ranging. They include automotive and aerospace parts, sail boats and bridge components.

6063 aluminum is the optimum extrusion alloy. It demonstrates excellent surface finish and is often used for decorative trim, exterior railing, and door frames. Because this grade has a poor strength-to-weight ratio, it should not be used for critical load bearing applications. It can be anodized to increase resistance to corrosion.

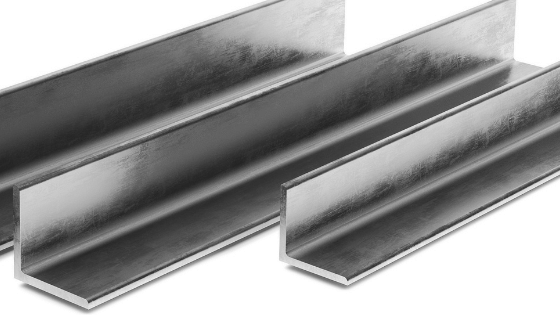

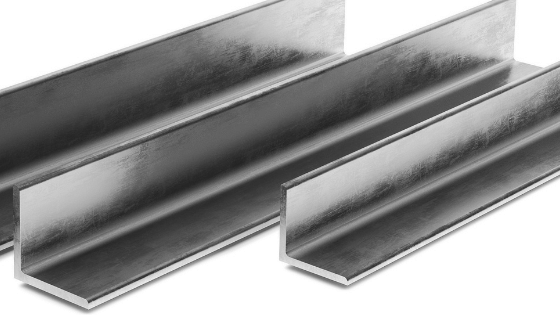

Angles have two legs. They can be equal or unequal lengths, and are arranged to form a 90 degree angle. Excellent weldability, extrudability, strength, corrosion resistance, moderate wear resistance, formability, and machinability make up some of the beneficial qualities for choosing aluminum angles. They are seen in structural and general engineering and manufacturing applications across a wide range of industries, including architectural, construction, and automotive.

ANSWER:ANSWER:

It is shaped like an uppercase-L, at 90 degrees. The legs can be of either equal or unequal lengths, and flanges can be either tapered (structural) or straight (architectural).

ANSWER:

Size will depend on the particular aluminum alloy angle product.

ANSWER:

It’s possible to think about angles as half of an aluminum channel. While an angle will form the letter L, an aluminum channel will form a straight-backed C or U. Because of their different shape, they have different applications. Typically speaking, channels can bear more weight.

ANSWER:ANSWER:

It is shaped like an uppercase-L, at 90 degrees. The legs can be of either equal or unequal lengths, and flanges can be either tapered (structural) or straight (architectural).

ANSWER:

Size will depend on the particular aluminum alloy angle product.

ANSWER:

It’s possible to think about angles as half of an aluminum channel. While an angle will form the letter L, an aluminum channel will form a straight-backed C or U. Because of their different shape, they have different applications. Typically speaking, channels can bear more weight.

What is aluminum oxidation and how important is it to aluminum corrosion resistance? According...

3003 aluminum sheet and 5052 aluminum sheet are typically known as “Common Alloys” because they...

5052 aluminum is popular because it is one of the most versatile aluminum alloys. It...

Aluminum ore is the most abundant metal element in the Earth’s crust. It is...

Aluminum alloys are known for their corrosion resistance, ductility, conductivity, appearance, strength, and most...

Corporate Average Fuel Economy (CAFE) Standards Since the adoption of new CAFE standards in...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: