304/304L stainless steel tube is popular across a wide range of industries. Kloeckner Metals is proud to stock it nationwide across our network of 40+ branches.

304/304L stainless steel tube is one of the most widely used stainless steel grades. It has a low carbon content and high chromium and nickel composition. It is readily drawn and formed, and shows good strength and outstanding corrosion resistance, including protection against intergranular corrosion during welding.

304 stainless is part of the austenitic steel family. One of the disadvantages of austenitic steels is that it cannot be hardened by heat treatment. This aside, 304 is an incredibly versatile stainless steel grade that can be readily drawn and formed. Both hardness and strength can be improved through cold working. It has good ductility in the annealed condition. Additionally, 304L demonstrates excellent corrosion resistance given its ultra low carbon makeup.

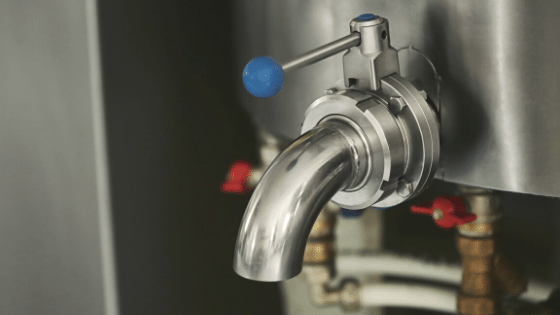

304 stainless steel tube can be seen in the aerospace, automotive, food and dairy, textile, pharmaceutical, and architecture industries, among others.

This grade is frequently purposed in chemical processing equipment across industries, from food and dairy, to pharmaceutical and textiles. It is also utilized for heat exchangers, construction materials, and kitchen equipment.

It is machinable.

304 stainless is weldable. Due to added intergranular corrosion protection, 304L performs better where weld quality in a corrosive environment is a major factor.

It is not heat treatable.

304 stainless is part of the austenitic steel family. One of the disadvantages of austenitic steels is that it cannot be hardened by heat treatment. This aside, 304 is an incredibly versatile stainless steel grade that can be readily drawn and formed. Both hardness and strength can be improved through cold working. It has good ductility in the annealed condition. Additionally, 304L demonstrates excellent corrosion resistance given its ultra low carbon makeup.

304 stainless steel tube can be seen in the aerospace, automotive, food and dairy, textile, pharmaceutical, and architecture industries, among others.

This grade is frequently purposed in chemical processing equipment across industries, from food and dairy, to pharmaceutical and textiles. It is also utilized for heat exchangers, construction materials, and kitchen equipment.

It is machinable.

304 stainless is weldable. Due to added intergranular corrosion protection, 304L performs better where weld quality in a corrosive environment is a major factor.

It is not heat treatable.

ANSWER:

The “as welded” state eliminates the need for annealing prior to welding, which saves time and resources. While 304 stainless steel tube can sometimes be used in the “as welded” state, the ultra low carbon in 304L adds protection against intergranular corrosion to produce more durable weldments.

ANSWER:

As temperatures increase, let’s say from room temperature to 1600°F, the mechanical properties of 304 will depreciate. For example, ultimate strength will drop from 586 MPa (85 ksi) to 110 MPa (16 ksi).

ANSWER:

The BHN for 304 stainless in the annealed condition is 150. Once cold drawn, the BHN increases to 277.

ANSWER:

The “as welded” state eliminates the need for annealing prior to welding, which saves time and resources. While 304 stainless steel tube can sometimes be used in the “as welded” state, the ultra low carbon in 304L adds protection against intergranular corrosion to produce more durable weldments.

ANSWER:

As temperatures increase, let’s say from room temperature to 1600°F, the mechanical properties of 304 will depreciate. For example, ultimate strength will drop from 586 MPa (85 ksi) to 110 MPa (16 ksi).

ANSWER:

The BHN for 304 stainless in the annealed condition is 150. Once cold drawn, the BHN increases to 277.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: