Kloeckner offers extensive drilling capabilities throughout our conveniently located network of North American service centers. Thanks to state-of-the-art equipment, Kloeckner can provide customers with expanded capabilities including first, second, and third stage processing. Servicing every stage of the supply chain, we give our customers the possibility for end-to-end supply chains to be invoiced through one supplier.

Answer:

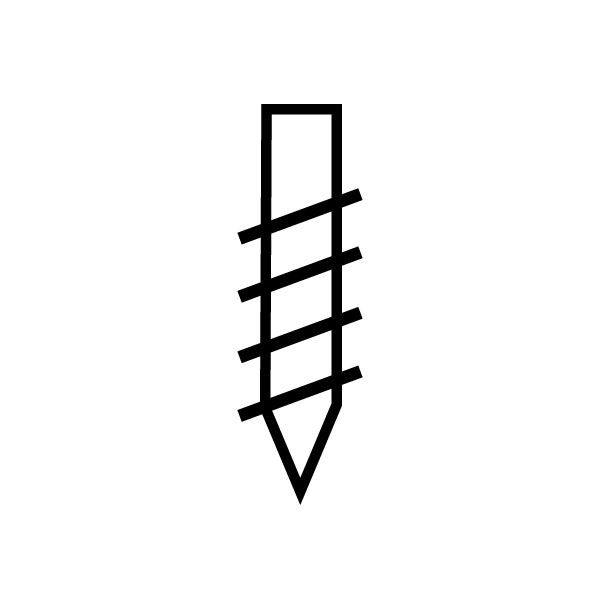

It is a metalworking process that involves creating holes in metal using a rotating cutting tool called a drill bit. It is held in a machine, which is used to apply force and rotate the drill bit into the metal. As the drill bit rotates, it cuts into the metal, removing material and creating a hole of a specific size and depth.

It is used in the metal industry for a wide range of applications, such as:

There are different types of machines used in the metal industry, including radial, pillar, and CNC drilling machines. The choice of machine depends on the specific application and material.

Answer:

Drilled metals have a wide range of applications across various industries. Some of the industries that commonly use drilled metals include:

Overall, the process is diverse and widespread across various industries.

What is drilling?

Answer:

It is a metalworking process that involves creating holes in metal using a rotating cutting tool called a drill bit. It is held in a machine, which is used to apply force and rotate the drill bit into the metal. As the drill bit rotates, it cuts into the metal, removing material and creating a hole of a specific size and depth.

It is used in the metal industry for a wide range of applications, such as:

There are different types of machines used in the metal industry, including radial, pillar, and CNC drilling machines. The choice of machine depends on the specific application and material.

What industries rely on drilling as a service?

Answer:

Drilled metals have a wide range of applications across various industries. Some of the industries that commonly use drilled metals include:

Overall, the process is diverse and widespread across various industries.

Capabilities A drilling, punching, and sheering system can provide a multitude of capabilities...

Humans are harnessing the wind’s energy with wind turbines, windmills, and other technologies...

When starting a new commercial or residential project, you will want the right...

What is a Metal Service Center? First things first, what is a metal...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: