Kloeckner Metals carries drill tables as core equipment across our nationwide network of 40+ branches. Contact us today for your drilling needs.

Answer:

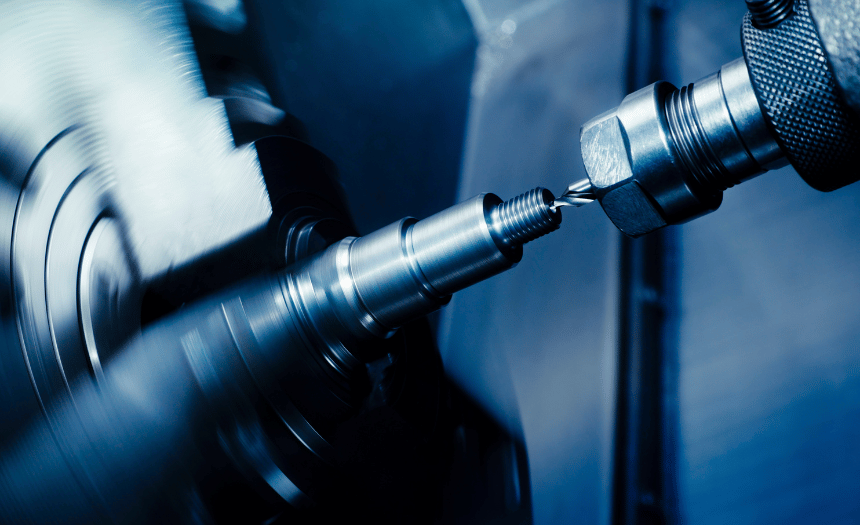

Drilling is a machining process used in the metals industry to create holes in metal components. The process involves using a rotating drill bit to remove material from the workpiece, creating a hole of the desired size and shape.

Drilling is a common operation in the metals industry, as many metal components require holes for various purposes, such as for attaching parts together, for allowing the passage of fluids or gases, or for decorative or aesthetic purposes.

There are several types of drilling operations used in the metals industry, including:

Drilling can be performed manually or with the use of automated equipment, depending on the size and complexity of the operation. Automated drilling machines, such as CNC drilling machines, are commonly used in the metals industry for their efficiency and precision.

Answer:

Drilling is a process that is used in many different industries that work with metals. Some of the industries that rely on drilling include:

Overall, drilling is a fundamental process in the metals industry and is used in many different industries for a wide range of applications. Its versatility, precision, and efficiency make it an essential process for the manufacture of many different types of metal components.

Answer:

Drilling is a common machining process used in the metals industry to create holes in metal components of various types and forms. The specific metal types that are drilled depend on the industry, application, and specific requirements of the final product.

In general, the metal types that are commonly drilled include:

Overall, drilling is a versatile process that can be used to create holes in a wide range of metal types and forms, including pipe, tube, bar, angles, channels, beams, sheet, and plate. The specific metal types that are drilled depend on the industry, application, and specific requirements of the final product.

How are drill tables used in the metals industry?

Answer:

Drilling is a machining process used in the metals industry to create holes in metal components. The process involves using a rotating drill bit to remove material from the workpiece, creating a hole of the desired size and shape.

Drilling is a common operation in the metals industry, as many metal components require holes for various purposes, such as for attaching parts together, for allowing the passage of fluids or gases, or for decorative or aesthetic purposes.

There are several types of drilling operations used in the metals industry, including:

Drilling can be performed manually or with the use of automated equipment, depending on the size and complexity of the operation. Automated drilling machines, such as CNC drilling machines, are commonly used in the metals industry for their efficiency and precision.

What industries rely on drill tables?

Answer:

Drilling is a process that is used in many different industries that work with metals. Some of the industries that rely on drilling include:

Overall, drilling is a fundamental process in the metals industry and is used in many different industries for a wide range of applications. Its versatility, precision, and efficiency make it an essential process for the manufacture of many different types of metal components.

What types of metals are frequently drilled?

Answer:

Drilling is a common machining process used in the metals industry to create holes in metal components of various types and forms. The specific metal types that are drilled depend on the industry, application, and specific requirements of the final product.

In general, the metal types that are commonly drilled include:

Overall, drilling is a versatile process that can be used to create holes in a wide range of metal types and forms, including pipe, tube, bar, angles, channels, beams, sheet, and plate. The specific metal types that are drilled depend on the industry, application, and specific requirements of the final product.

Humans are harnessing the wind’s energy with wind turbines, windmills, and other technologies...

When starting a new commercial or residential project, you will want the right...

What is a Metal Service Center? First things first, what is a metal...

Structural steel shapes provide support to buildings of all kinds. They’re integral to...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: