Kloeckner offers considerable precision leveling capabilities throughout our North American service centers. Committed to our promise to be an end-to-end value chain supplier to our customers, we offer an unprecedented range of standard products and custom processes, and routinely build products exactly to customer specification no matter the dimension or tolerance. The end result is that customers can get their entire supply chain invoiced through us, saving valuable resources. Still not satisfied, we add in sophisticated warehousing options, completely inventory management, and expert consultation.

Answer:

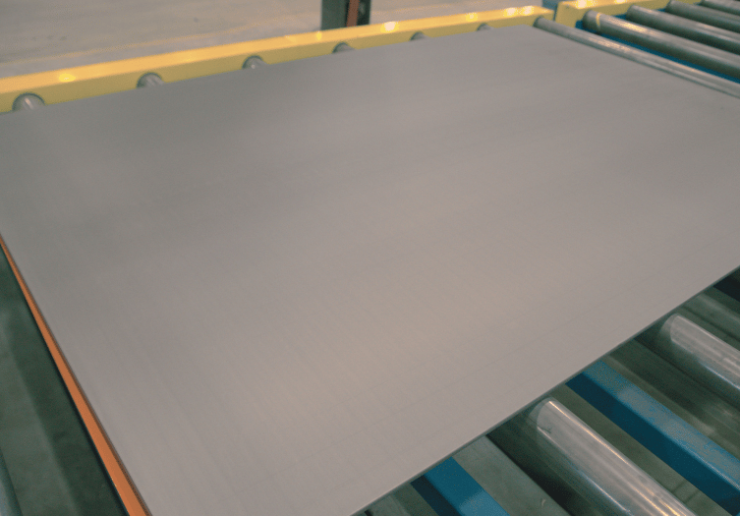

Precision leveling is a metal processing technique used to flatten and remove any residual stress in metal sheets or coils. The process involves passing a metal sheet or coil—like aluminum coil—through a series of rollers that stretch, bend, and compress the metal to remove any deviations from flatness.

Precision leveling is typically used to produce high-quality, flat metal sheets or coils with a very tight dimensional tolerance. The process is commonly used in industries such as automotive and construction, where flatness and dimensional accuracy are critical for the performance of parts and components.

The process of precision leveling involves several stages, including:

Precision leveling can be used on a variety of metals, including carbon steel, aluminum, and stainless steel. The choice of metal will depend on the requirements of the application, such as strength, durability, and resistance to corrosion.

The benefits of precision leveling include improved flatness and dimensional accuracy, reduced material waste, and increased productivity. By producing high-quality, flat metal sheets or coils, precision leveling can improve the performance and reliability of parts and components, leading to increased customer satisfaction and profitability.

Answer:

No, they are not the same. While both types of leveling machines are used to flatten and remove any residual stress in metal sheets or coils, they use different methods to achieve the desired result.

A precision leveler is a machine that uses a series of rollers to precisely and uniformly stretch, bend, and compress the metal sheet or coil to remove any deviations from flatness. The precision leveling process is typically used to achieve a very high degree of flatness, with tolerances as tight as ±0.005 inches.

On the other hand, a corrective leveler is a machine that uses a set of rollers that are slightly offset from each other to remove residual stresses in the metal sheet or coil. The corrective leveling process is typically used to remove any bow or camber in the metal, resulting in a flat sheet or coil.

While corrective leveling can improve flatness to some degree, it typically does not achieve the same high level of precision as precision leveling. Corrective leveling is often used as a secondary operation to complement other processing techniques, such as slitting or cut-to-length, whereas precision leveling is typically used as a primary operation to produce flat and stress-free metal sheets or coils.

What is precision leveling?

Answer:

Precision leveling is a metal processing technique used to flatten and remove any residual stress in metal sheets or coils. The process involves passing a metal sheet or coil—like aluminum coil—through a series of rollers that stretch, bend, and compress the metal to remove any deviations from flatness.

Precision leveling is typically used to produce high-quality, flat metal sheets or coils with a very tight dimensional tolerance. The process is commonly used in industries such as automotive and construction, where flatness and dimensional accuracy are critical for the performance of parts and components.

The process of precision leveling involves several stages, including:

Precision leveling can be used on a variety of metals, including carbon steel, aluminum, and stainless steel. The choice of metal will depend on the requirements of the application, such as strength, durability, and resistance to corrosion.

The benefits of precision leveling include improved flatness and dimensional accuracy, reduced material waste, and increased productivity. By producing high-quality, flat metal sheets or coils, precision leveling can improve the performance and reliability of parts and components, leading to increased customer satisfaction and profitability.

Is a corrective leveler the same as a precision leveler?

Answer:

No, they are not the same. While both types of leveling machines are used to flatten and remove any residual stress in metal sheets or coils, they use different methods to achieve the desired result.

A precision leveler is a machine that uses a series of rollers to precisely and uniformly stretch, bend, and compress the metal sheet or coil to remove any deviations from flatness. The precision leveling process is typically used to achieve a very high degree of flatness, with tolerances as tight as ±0.005 inches.

On the other hand, a corrective leveler is a machine that uses a set of rollers that are slightly offset from each other to remove residual stresses in the metal sheet or coil. The corrective leveling process is typically used to remove any bow or camber in the metal, resulting in a flat sheet or coil.

While corrective leveling can improve flatness to some degree, it typically does not achieve the same high level of precision as precision leveling. Corrective leveling is often used as a secondary operation to complement other processing techniques, such as slitting or cut-to-length, whereas precision leveling is typically used as a primary operation to produce flat and stress-free metal sheets or coils.

Aluminum is no doubt one of the most popular metals, shaping the capabilities...

Stainless steel finishes offer a range of benefits. You can think about finishing...

Since stainless steel is aesthetically pleasing and corrosion resistant, it’s often used in...

There are infinite possibilities for automotive aluminum sheet. With thousands of car parts...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: