Kloeckner is committed to providing end-to-end press braking services and offers customers both first and second stage press braking.

Kloeckner provides customers with first and second stage press braking capabilities, processing on demand to customer specification, and just-in-time delivery. Thanks to our state-of-the-art equipment, Kloeckner offers customers the opportunity to do the entire press braking process at a single facility, giving customers a unique opportunity to simplify the ordering process and have their end-to-end supply chains invoiced through one supplier.

Answer:

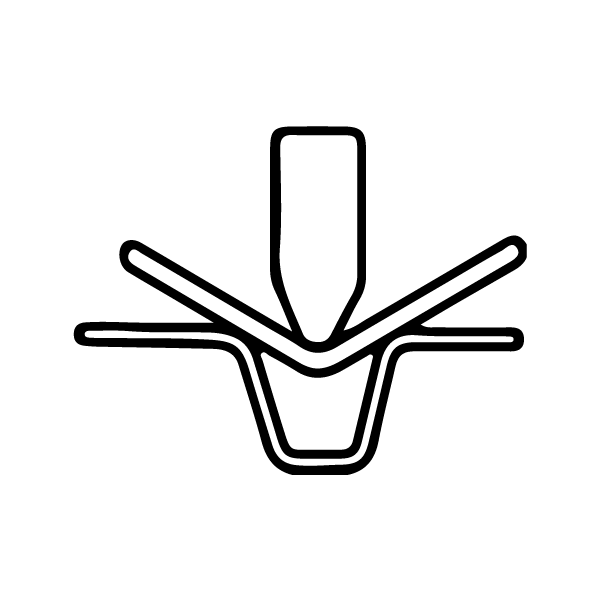

Press braking is a metal forming process used to bend and shape sheet metal and plate materials. The process involves using a hydraulic or mechanical press brake machine to apply force to the metal, which causes it to bend and form into a desired shape.

The machine consists of a flat bed or table with a bottom die and a top punch. The sheet metal or plate material is placed on the bed, and the top punch is lowered to press the material against the bottom die. The force applied by the machine causes the material to bend and form into the desired shape.

The process can be used to create a wide range of shapes and forms, including angles, channels, cylinders, and cones. It is commonly used in industries such as construction, automotive, aerospace, and manufacturing to create parts and components for various applications.

The advantages include the ability to create complex shapes and forms with high precision and accuracy. It is also a cost-effective method for creating small to medium production runs of parts and components.

The limitations include the inability to form sharp angles or bends in some materials, and the need for specialized tooling and dies to create specific shapes and forms. The thickness and width of the material being bent is also an important factor in determining the feasibility of press braking.

What is press braking?

Answer:

Press braking is a metal forming process used to bend and shape sheet metal and plate materials. The process involves using a hydraulic or mechanical press brake machine to apply force to the metal, which causes it to bend and form into a desired shape.

The machine consists of a flat bed or table with a bottom die and a top punch. The sheet metal or plate material is placed on the bed, and the top punch is lowered to press the material against the bottom die. The force applied by the machine causes the material to bend and form into the desired shape.

The process can be used to create a wide range of shapes and forms, including angles, channels, cylinders, and cones. It is commonly used in industries such as construction, automotive, aerospace, and manufacturing to create parts and components for various applications.

The advantages include the ability to create complex shapes and forms with high precision and accuracy. It is also a cost-effective method for creating small to medium production runs of parts and components.

The limitations include the inability to form sharp angles or bends in some materials, and the need for specialized tooling and dies to create specific shapes and forms. The thickness and width of the material being bent is also an important factor in determining the feasibility of press braking.

Today is my birthday. So what better way to celebrate than to talk...

The main benefit of Kloeckner Metals Santa Fe Springs’ new 52-foot Cincinnati Press...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: