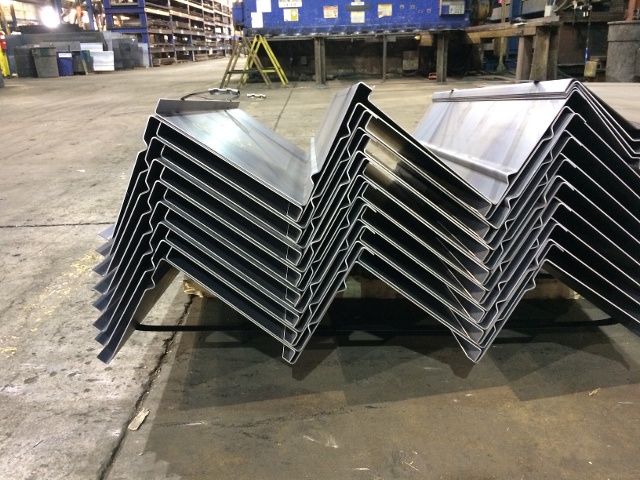

Kloeckner provides a wide variety of end finishing equipment and services to help you meet customer demand. No matter what your needs, choose Kloeckner.

Kloeckner offers broad end finishing capabilities throughout our branches with the option for customers to get their end-to-end supply chains invoiced through one supplier. With a wide range of standard products and custom processes available, our customers can get their products processed exactly how they want. In addition, we’re proud to offer a complete ordering experience that includes state-of-the-art warehousing services, complete supply chain management, and, of course, expert consultation throughout.

Answer:

End finishing in the metals industry refers to the process of shaping and smoothing the ends of metal parts after they have been stamped or cut. This process is important because it helps to ensure that the ends of the parts are uniform, smooth, and free of burrs or other imperfections that could cause problems during assembly or use.

There are several different end finishing techniques that can be used, depending on the specific requirements of the application and the type of metal being used. Some common end finishing techniques include:

Each of these end finishing techniques has its own specific set of benefits and applications, and the choice of technique will depend on the specific requirements of the application. For example, deburring may be sufficient for removing burrs from the ends of parts, while beveling may be necessary for improving the appearance of parts that will be visible in an assembled product.

What is end finishing?

Answer:

End finishing in the metals industry refers to the process of shaping and smoothing the ends of metal parts after they have been stamped or cut. This process is important because it helps to ensure that the ends of the parts are uniform, smooth, and free of burrs or other imperfections that could cause problems during assembly or use.

There are several different end finishing techniques that can be used, depending on the specific requirements of the application and the type of metal being used. Some common end finishing techniques include:

Each of these end finishing techniques has its own specific set of benefits and applications, and the choice of technique will depend on the specific requirements of the application. For example, deburring may be sufficient for removing burrs from the ends of parts, while beveling may be necessary for improving the appearance of parts that will be visible in an assembled product.

Stainless steel finishes offer a range of benefits. You can think about finishing...

When starting a new commercial or residential project, you will want the right...

Chromium Stainless Steel plays a unique role in metallurgy. Stainless steels are first...

Welding aluminum makes countless products possible. Like auto pistons, aircraft, marine valves, bikes,...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: