Providing the latest stamping capabilities is one of our top priorities. Whatever your stamping needs, choose Kloeckner.

Kloeckner offers extensive stamping capabilities throughout our numerous North American service centers. Thanks to our end-to-end supply chains, our customers get the added advantage of invoicing their entire product line through one supplier. All products can be processed to exact customer dimensional and tolerance specification as part of a seamless ordering experience that includes sophisticated warehousing and logistics services, complete inventory management, and expert consultation throughout.

Answer:

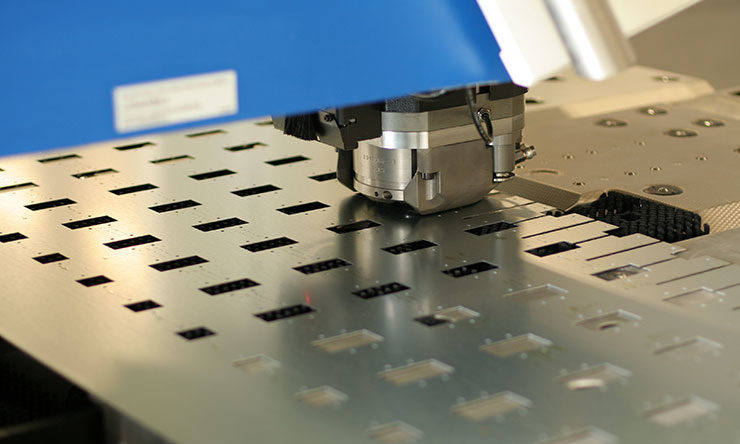

Metal stamping is a metal forming process that involves cutting, bending, and shaping metal into a desired shape or form using a stamping press. The process typically starts with a flat metal sheet or coil, which is placed into a stamping press. The press then uses a series of dies to cut, bend, and shape the metal into the desired form.

Metal stamping can be used to produce a wide range of products, including automotive parts, electrical components, and consumer goods. The process is highly automated and can produce parts quickly and efficiently, making it a cost-effective method for mass-producing metal products.

There are many different types of metal stamping processes, including blanking, punching, forming, drawing, and coining. The choice of process will depend on the specific requirements of the application, including the size and shape of the product, the type of metal being used, and the desired properties of the finished product.

Metal stamping is widely used in many industries, including automotive, aerospace, construction, consumer goods, and manufacturing, where the need for high-volume, low-cost metal products is required. The process is known for its high accuracy and consistency, making it an ideal method for producing metal parts with precise dimensions and uniform quality.

What is metal stamping?

Answer:

Metal stamping is a metal forming process that involves cutting, bending, and shaping metal into a desired shape or form using a stamping press. The process typically starts with a flat metal sheet or coil, which is placed into a stamping press. The press then uses a series of dies to cut, bend, and shape the metal into the desired form.

Metal stamping can be used to produce a wide range of products, including automotive parts, electrical components, and consumer goods. The process is highly automated and can produce parts quickly and efficiently, making it a cost-effective method for mass-producing metal products.

There are many different types of metal stamping processes, including blanking, punching, forming, drawing, and coining. The choice of process will depend on the specific requirements of the application, including the size and shape of the product, the type of metal being used, and the desired properties of the finished product.

Metal stamping is widely used in many industries, including automotive, aerospace, construction, consumer goods, and manufacturing, where the need for high-volume, low-cost metal products is required. The process is known for its high accuracy and consistency, making it an ideal method for producing metal parts with precise dimensions and uniform quality.

Stainless Steel: A Consumer Favorite If you know anything about metals or live...

Comparing 5052 vs 6063 aluminum, you’ll see they’re both two very common alloys in the...

Aluminum is no doubt one of the most popular metals, shaping the capabilities...

Stainless steel finishes offer a range of benefits. You can think about finishing...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: