Let Kloeckner’s experienced thermal and plasma cutting experts provide guidance on all of your plate processing needs.

Kloeckner offers thorough plate processing capabilities in our branches throughout North America. Our commitment to serving customers at the highest levels means we’re dedicated to providing the widest range of standard and custom products available. Because we process products precisely to customer specification in addition to stocking a full assortment of standard product, our customers routinely have their entire supply chains invoiced through us. Still not satisfied, we also offer sophisticated logistics services, total inventory management, and expert consultation throughout.

Answer:

Plate processing typically refers to the various techniques and procedures involved in the fabrication, modification, or treatment of steel plates. They are commonly used in industries such as construction, manufacturing, automotive, aerospace, and more.

Plate processing may involve several steps, and some of the common processes include:

Plate processing is an integral part of the metalworking industry and plays a significant role in creating a wide range of products, from simple metal sheets to complex structures used in various applications. The processes used may vary depending on the specific requirements and the type of metal being processed.

Answer:

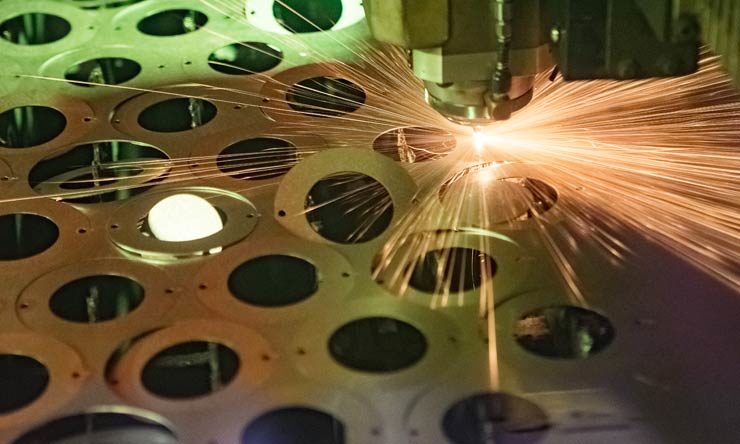

Thermal cutting and plasma cutting are two common methods used to cut metal, but they differ in the way they generate heat to melt and cut through the metal.

Thermal cutting is a general term that refers to any process that uses heat to cut through metal. The most common types of thermal cutting are oxy-fuel cutting and laser cutting. In oxy-fuel cutting, a mixture of fuel gas and oxygen is used to create a flame that melts the metal and a jet of high-pressure oxygen is used to blow away the molten metal, resulting in a cut. In laser cutting, a high-energy laser beam is used to melt and cut through the metal.

Plasma cutting, on the other hand, is a specific type of thermal cutting that uses a plasma arc to melt and cut through metal. The plasma arc is generated by passing a gas through a constricted opening and then adding an electrical current to ionize the gas, which creates a plasma that can melt and cut through metal.

The main difference between thermal cutting and plasma cutting is the way the heat is generated. In thermal cutting, heat is generated either by combustion (in the case of oxy-fuel cutting) or by the laser beam. In plasma cutting, heat is generated by the plasma arc. Plasma cutting is typically faster and more precise than oxy-fuel cutting, and it can be used on a wider range of materials, including non-ferrous metals such as aluminum.

In summary, while both thermal cutting and plasma cutting are plate processing services used to cut metal, plasma cutting is a specific type of thermal cutting that uses a plasma arc to generate heat and is typically faster and more precise than oxy-fuel cutting.

Answer:

When it comes to heavy steel plate cutting, the most suitable thermal cutting technique is usually oxy-fuel cutting. This is because oxy-fuel cutting is a highly efficient cutting process that can cut through thick steel plates quickly and with high precision.

In oxy-fuel cutting, a mixture of fuel gas and oxygen is used to create a flame that heats the metal to its ignition point, causing it to melt and be blown away by a jet of high-pressure oxygen. The process can be used to cut through steel plates up to several feet thick, making it an ideal choice for heavy steel plate cutting.

One of the advantages of oxy-fuel cutting is that it is a relatively low-cost cutting method compared to other thermal cutting techniques, such as laser cutting. Additionally, oxy-fuel cutting can be used in a wide range of applications, including metal fabrication, shipbuilding, and construction.

What is plate processing?

Answer:

Plate processing typically refers to the various techniques and procedures involved in the fabrication, modification, or treatment of steel plates. They are commonly used in industries such as construction, manufacturing, automotive, aerospace, and more.

Plate processing may involve several steps, and some of the common processes include:

Plate processing is an integral part of the metalworking industry and plays a significant role in creating a wide range of products, from simple metal sheets to complex structures used in various applications. The processes used may vary depending on the specific requirements and the type of metal being processed.

What is the difference between thermal and plasma cutting?

Answer:

Thermal cutting and plasma cutting are two common methods used to cut metal, but they differ in the way they generate heat to melt and cut through the metal.

Thermal cutting is a general term that refers to any process that uses heat to cut through metal. The most common types of thermal cutting are oxy-fuel cutting and laser cutting. In oxy-fuel cutting, a mixture of fuel gas and oxygen is used to create a flame that melts the metal and a jet of high-pressure oxygen is used to blow away the molten metal, resulting in a cut. In laser cutting, a high-energy laser beam is used to melt and cut through the metal.

Plasma cutting, on the other hand, is a specific type of thermal cutting that uses a plasma arc to melt and cut through metal. The plasma arc is generated by passing a gas through a constricted opening and then adding an electrical current to ionize the gas, which creates a plasma that can melt and cut through metal.

The main difference between thermal cutting and plasma cutting is the way the heat is generated. In thermal cutting, heat is generated either by combustion (in the case of oxy-fuel cutting) or by the laser beam. In plasma cutting, heat is generated by the plasma arc. Plasma cutting is typically faster and more precise than oxy-fuel cutting, and it can be used on a wider range of materials, including non-ferrous metals such as aluminum.

In summary, while both thermal cutting and plasma cutting are plate processing services used to cut metal, plasma cutting is a specific type of thermal cutting that uses a plasma arc to generate heat and is typically faster and more precise than oxy-fuel cutting.

What thermal cutting technique is best for heavy steel plate?

Answer:

When it comes to heavy steel plate cutting, the most suitable thermal cutting technique is usually oxy-fuel cutting. This is because oxy-fuel cutting is a highly efficient cutting process that can cut through thick steel plates quickly and with high precision.

In oxy-fuel cutting, a mixture of fuel gas and oxygen is used to create a flame that heats the metal to its ignition point, causing it to melt and be blown away by a jet of high-pressure oxygen. The process can be used to cut through steel plates up to several feet thick, making it an ideal choice for heavy steel plate cutting.

One of the advantages of oxy-fuel cutting is that it is a relatively low-cost cutting method compared to other thermal cutting techniques, such as laser cutting. Additionally, oxy-fuel cutting can be used in a wide range of applications, including metal fabrication, shipbuilding, and construction.

When starting a new commercial or residential project, you will want the right...

What is Plasma? Before we can answer what is plasma cutting, we have...

Capabilities A drilling, punching, and sheering system can provide a multitude of capabilities...

The Messer MPC 2000 is a multi-process cutting machine that can be equipped...

Messer Cutting Systems TMC 4500 DB is a heavy-duty dual beam cutting machine...

Today’s branch spotlight takes us to the land of deep dish pizza, full...

It’s time to celebrate one of our veteran branches, located just outside of...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: