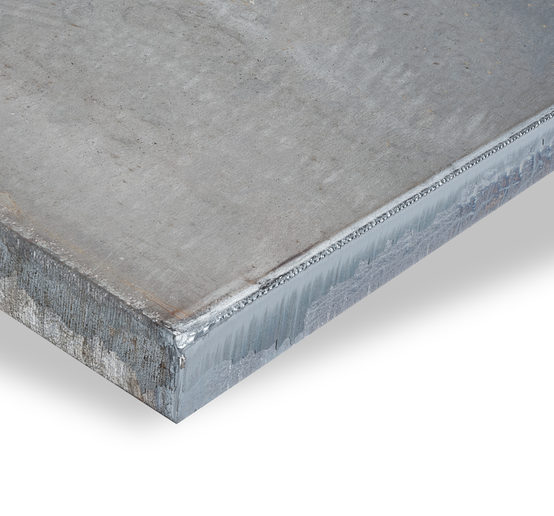

Kloeckner Metals supports the American shipbuilding industry through its dedication to high-quality marine & offshore steel plate. Kloeckner supplies marine grade steel plate in a variety of grades and thicknesses throughout North America.

A131 is a structural steel that is used almost exclusively in shipbuilding. A131, otherwise known as ABS for the American Bureau of Shipping that certifies it, has ordinary strength and a minimum yield of 34 KSI. It is used in barges, ship construction, and marine equipment.

ABS steel plates are offered in three different grades, AH36, DH36, and FH36. The plates are higher-strength steel grades and are certified by the American Bureau of Shipbuilding (ABS). Some typical applications are the building of structural parts of ships, marine equipment, and barges.

Already a Kloeckner customer? Shop ABS AH36 and DH36 on Kloeckner Direct.

API 2H is offered in grade 50 and provides intermediate strength compared to other structural steel grades. This steel has a high impact toughness and resistance to fatigue loading. A typical application for API 2H steel is offshore construction in the welded construction industry.

A633 steel plate is an excellent steel for welding, riveting, or bolting. It is a normalized high-strength structural steel grade and offers strong notch toughness in lower temperatures. The typical applications for the A633 are utility poles as plates, construction frames, suspension components, electric shovel dipper, and offshore platforms.

Already a customer? Shop A633 on Kloeckner Direct.

A131 is a structural steel that is used almost exclusively in shipbuilding. A131, otherwise known as ABS for the American Bureau of Shipping that certifies it, has ordinary strength and a minimum yield of 34 KSI. It is used in barges, ship construction, and marine equipment.

ABS steel plates are offered in three different grades, AH36, DH36, and FH36. The plates are higher-strength steel grades and are certified by the American Bureau of Shipbuilding (ABS). Some typical applications are the building of structural parts of ships, marine equipment, and barges.

Already a Kloeckner customer? Shop ABS AH36 and DH36 on Kloeckner Direct.

API 2H is offered in grade 50 and provides intermediate strength compared to other structural steel grades. This steel has a high impact toughness and resistance to fatigue loading. A typical application for API 2H steel is offshore construction in the welded construction industry.

A633 steel plate is an excellent steel for welding, riveting, or bolting. It is a normalized high-strength structural steel grade and offers strong notch toughness in lower temperatures. The typical applications for the A633 are utility poles as plates, construction frames, suspension components, electric shovel dipper, and offshore platforms.

Already a customer? Shop A633 on Kloeckner Direct.

Shipbuilding is central to America’s identity and American ingenuity shines in its submarines, yachts, cruise ships, and aircraft carriers. Great ships start with high-quality marine grade steel plate and Kloeckner Metals is proud to supply the American shipbuilding industry with marine and offshore steel that’s corrosion-resistant and tough, demonstrating decreased brittleness, even in cold temperatures, and increased strength to resist force trauma and vibration. All of our marine grade plate meets the standards set by ABS (American Bureau of Shipbuilding), ASTM, and API (American Petroleum Institute). We’re a trusted supplier of marine & offshore steel plate across America and service shipbuilders from our network of 40+ branches nationwide.

ANSWER:

To be considered a marine grade, the material must be able to resist corrosive effects that are common in a water environment. To achieve this, special alloying elements are added to these grades in order to defend against corrosion. While most carbon steel is not suited for marine environments, there are several marine grade carbon steels that have been approved by the American Bureau of Shipping for use in shipbuilding applications.

ANSWER:

Marine grade metals include carbon steel, alloy steel, aluminum, stainless steel, copper, bronze, brass, and galvanized steel. Each metal has distinctive chemical and physical properties that make them best suited for different applications in marine conditions.

ANSWER:

Marine grade means that the carbon or alloy steel has been approved by the American Bureau of Shipping for use in shipbuilding applications.

ANSWER:

You’ll typically find marine & offshore steel plate in structural shipbuilding and other offshore structural applications.

ANSWER:

To be considered a marine grade, the material must be able to resist corrosive effects that are common in a water environment. To achieve this, special alloying elements are added to these grades in order to defend against corrosion. While most carbon steel is not suited for marine environments, there are several marine grade carbon steels that have been approved by the American Bureau of Shipping for use in shipbuilding applications.

ANSWER:

Marine grade metals include carbon steel, alloy steel, aluminum, stainless steel, copper, bronze, brass, and galvanized steel. Each metal has distinctive chemical and physical properties that make them best suited for different applications in marine conditions.

ANSWER:

Marine grade means that the carbon or alloy steel has been approved by the American Bureau of Shipping for use in shipbuilding applications.

ANSWER:

You’ll typically find marine & offshore steel plate in structural shipbuilding and other offshore structural applications.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: