Answer:

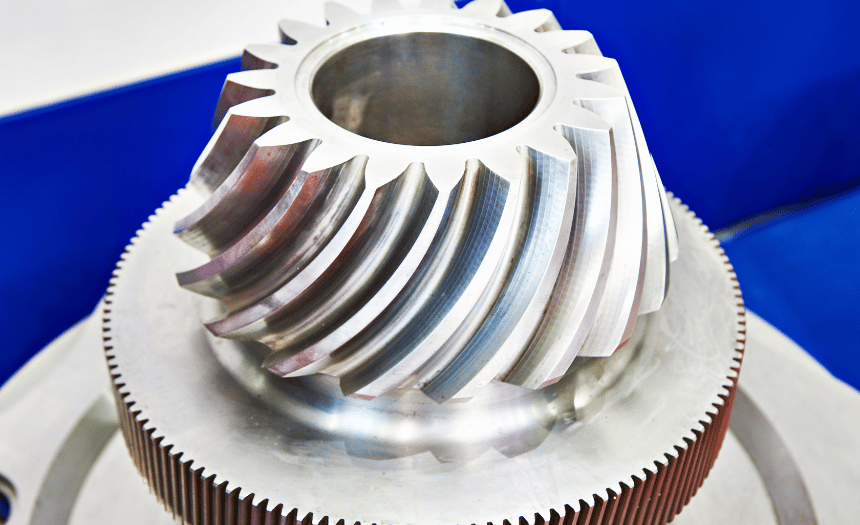

It is a process of cutting or shaping metal at an angle using a plasma torch. During the process, a high-velocity jet of ionized gas (plasma) is directed onto the surface of the metal, melting and vaporizing the metal to create a cut or a shape. The plasma torch is mounted on a computer-controlled cutting machine that can precisely control the angle and depth of the bevel cut.

It is commonly used in the metal fabrication industry for cutting and shaping metal parts with angled edges or chamfers. The process is often used for cutting bevels on thick metal plates or pipes, as it is faster and more cost-effective than traditional methods such as oxy-fuel cutting or mechanical beveling.

Plasma beveling offers several advantages over other beveling techniques, including:

It is commonly used in a variety of industries, including construction, automotive, aerospace, and manufacturing, where precise and efficient beveling is required.

Answer:

Plasma cutting technology can be used to bevel a wide range of metal shapes, including sheet, plate, pipe, tube, bar, angle, beam, and channel. The ability to bevel these different shapes allows for more flexibility and versatility in the fabrication and manufacturing process.

Here are some examples of how plasma beveling can be applied to different metal shapes:

Overall, plasma beveling is a versatile and efficient method for creating angled edges on various metal shapes, which is widely used in many industries for welding and fabrication applications.

What is plasma beveling?

Answer:

It is a process of cutting or shaping metal at an angle using a plasma torch. During the process, a high-velocity jet of ionized gas (plasma) is directed onto the surface of the metal, melting and vaporizing the metal to create a cut or a shape. The plasma torch is mounted on a computer-controlled cutting machine that can precisely control the angle and depth of the bevel cut.

It is commonly used in the metal fabrication industry for cutting and shaping metal parts with angled edges or chamfers. The process is often used for cutting bevels on thick metal plates or pipes, as it is faster and more cost-effective than traditional methods such as oxy-fuel cutting or mechanical beveling.

Plasma beveling offers several advantages over other beveling techniques, including:

It is commonly used in a variety of industries, including construction, automotive, aerospace, and manufacturing, where precise and efficient beveling is required.

What metal types are frequently plasma beveled?

Answer:

Plasma cutting technology can be used to bevel a wide range of metal shapes, including sheet, plate, pipe, tube, bar, angle, beam, and channel. The ability to bevel these different shapes allows for more flexibility and versatility in the fabrication and manufacturing process.

Here are some examples of how plasma beveling can be applied to different metal shapes:

Overall, plasma beveling is a versatile and efficient method for creating angled edges on various metal shapes, which is widely used in many industries for welding and fabrication applications.

What is Plasma? Before we can answer what is plasma cutting, we have...

It’s time to celebrate one of our veteran branches, located just outside of...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: