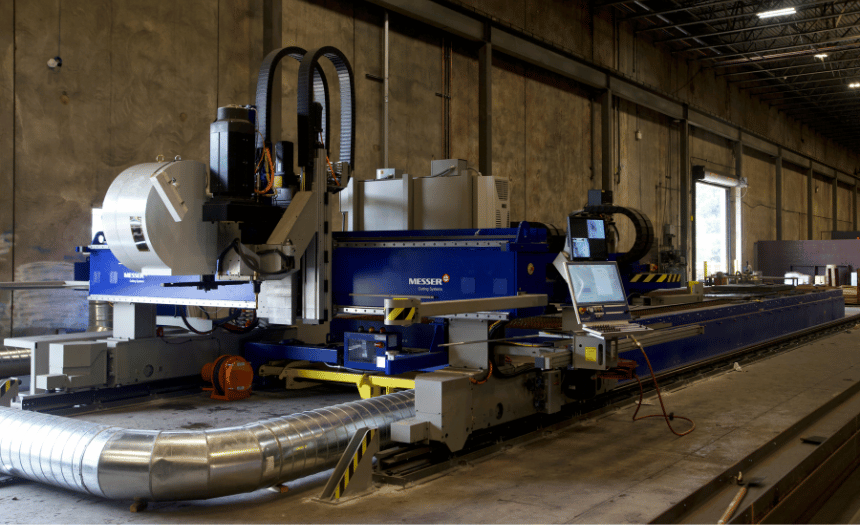

Kloeckner Metals is proud to carry the Messer Cutting Systems TMC 4500DB. Complete with 4 oxy-fuel torches and 4 plasma torches, this machine gives us the ability to drill up to 4-inch thick material with a 4-inch diameter hole. Drilling a small hole in thick material with a cleaner finish and truer tolerance offers more functionality on finished products – benefiting customers in the structural, commercial, and building supplies industries.

Answer:

The Messer TMC 4500DB is a CNC (Computer Numerical Control) cutting machine used in metal fabrication and industrial applications. It is a high-performance cutting machine designed to handle a wide range of metal products, including plates, sheets, and structural sections.

The machine is equipped with both plasma cutting and oxy-fuel cutting processes, which allows for versatile cutting capabilities. The plasma cutting process uses a high-temperature plasma arc to melt and cut through the metal, while the oxy-fuel cutting process uses a flame created by oxygen and a fuel gas to melt and cut through the metal.

The Messer TMC 4500DB is designed to handle large and thick metal products, with the ability to cut materials up to 10 inches thick. It features a heavy-duty cutting head and a robust gantry system, which allows for precise and efficient cutting of large and thick materials.

The machine is equipped with a CNC controller and software, which allows for efficient and automated cutting of complex shapes and designs. The cutting paths are created using CAD/CAM software, which allows for precise control over the cutting process.

Overall, the Messer TMC 4500DB is a versatile and efficient cutting tool that can handle a wide range of metal products with high precision and speed. It is commonly used in industries such as construction, shipbuilding, and manufacturing, where cutting of large and thick metal products is required.

What is the Messer TMC 4500DB?

Answer:

The Messer TMC 4500DB is a CNC (Computer Numerical Control) cutting machine used in metal fabrication and industrial applications. It is a high-performance cutting machine designed to handle a wide range of metal products, including plates, sheets, and structural sections.

The machine is equipped with both plasma cutting and oxy-fuel cutting processes, which allows for versatile cutting capabilities. The plasma cutting process uses a high-temperature plasma arc to melt and cut through the metal, while the oxy-fuel cutting process uses a flame created by oxygen and a fuel gas to melt and cut through the metal.

The Messer TMC 4500DB is designed to handle large and thick metal products, with the ability to cut materials up to 10 inches thick. It features a heavy-duty cutting head and a robust gantry system, which allows for precise and efficient cutting of large and thick materials.

The machine is equipped with a CNC controller and software, which allows for efficient and automated cutting of complex shapes and designs. The cutting paths are created using CAD/CAM software, which allows for precise control over the cutting process.

Overall, the Messer TMC 4500DB is a versatile and efficient cutting tool that can handle a wide range of metal products with high precision and speed. It is commonly used in industries such as construction, shipbuilding, and manufacturing, where cutting of large and thick metal products is required.

Messer Cutting Systems TMC 4500 DB is a heavy-duty dual beam cutting machine...

The Messer MPC 2000 is a multi-process cutting machine that can be equipped...

When starting a new commercial or residential project, you will want the right...

Structural steel shapes provide support to buildings of all kinds. They’re integral to...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: