Kloeckner is at the forefront of the North American metals industry with new equipment and expanded slitting capabilities.

Kloeckner offers slitting capabilities throughout the many service centers and branches that comprise our North American footprint. With such an expansive range of standard product and custom processes, we give our customers the unique opportunity to invoice their entire supply chain through one supplier. That’s not the only way we help our customer save on operational costs. We also offer state-of-the-art warehousing services, Industry 2.0 inventory management, and expert consultation throughout the ordering process.

Answer:

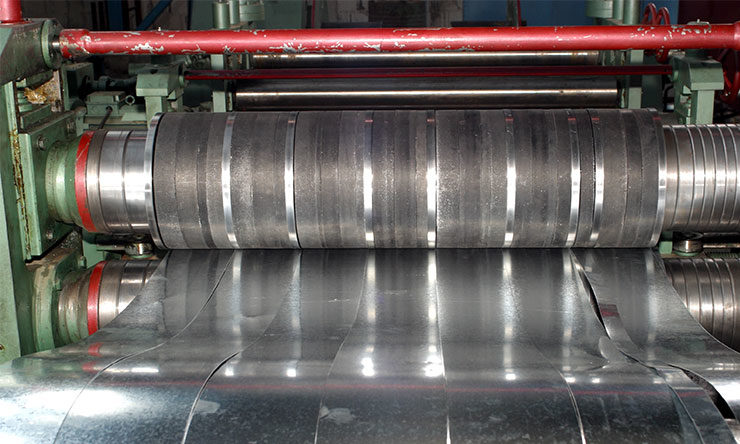

Slitting is a metal processing technique used to cut a large metal coil into narrower strips of a specific width. The process involves feeding a metal coil through a set of circular blades, which slit or cut the metal into smaller strips. The resulting metal strips are typically wound into smaller coils or cut-to-length pieces for further processing or use.

Slitting is commonly used in a wide range of industries, including automotive, construction, electrical, and manufacturing. The process is ideal for producing large quantities of narrow strips of metal that are used for a variety of applications, such as electrical components, automotive parts, metal roofing, and packaging.

The slitting process can be done with a variety of metals, including steel, aluminum, and stainless steel. The thickness of the metal being slit can vary, from thin sheet metal to thick steel plate. The width of the resulting metal strips can also vary, depending on the specific requirements of the application.

Slitting can be done in a variety of ways, depending on the type of metal being slit and the specific requirements of the application. The process may involve using different types of blades, lubricants, and tension controls to ensure that the resulting metal strips are of the desired width, thickness, and quality.

Answer:

Aluminum slitting is a process in which a large roll of aluminum coil is cut into smaller coils or strips of specific widths. The process involves unwinding the coil and passing it through a series of rotary knives or blades that cut the aluminum into the desired widths. The narrower strips are then rewound onto smaller rolls, which can be used as raw material for further processing or sold as-is.

Slitting is commonly used in the aluminum industry to produce materials for a wide range of applications, such as automotive components, building materials, packaging, and consumer goods. The process can be performed with various grades and alloys of aluminum, depending on the specific application and desired properties of the final product.

The slitting process requires specialized equipment, such as a slitting line, which typically includes a decoiler to unwind the coil, a slitter to cut the aluminum into strips, and a recoiler to wind the strips onto smaller coils. The process is often automated to ensure consistent quality and reduce labor costs, and can be performed at high speeds to meet production demands.

What is slitting?

Answer:

Slitting is a metal processing technique used to cut a large metal coil into narrower strips of a specific width. The process involves feeding a metal coil through a set of circular blades, which slit or cut the metal into smaller strips. The resulting metal strips are typically wound into smaller coils or cut-to-length pieces for further processing or use.

Slitting is commonly used in a wide range of industries, including automotive, construction, electrical, and manufacturing. The process is ideal for producing large quantities of narrow strips of metal that are used for a variety of applications, such as electrical components, automotive parts, metal roofing, and packaging.

The slitting process can be done with a variety of metals, including steel, aluminum, and stainless steel. The thickness of the metal being slit can vary, from thin sheet metal to thick steel plate. The width of the resulting metal strips can also vary, depending on the specific requirements of the application.

Slitting can be done in a variety of ways, depending on the type of metal being slit and the specific requirements of the application. The process may involve using different types of blades, lubricants, and tension controls to ensure that the resulting metal strips are of the desired width, thickness, and quality.

What is aluminum slitting?

Answer:

Aluminum slitting is a process in which a large roll of aluminum coil is cut into smaller coils or strips of specific widths. The process involves unwinding the coil and passing it through a series of rotary knives or blades that cut the aluminum into the desired widths. The narrower strips are then rewound onto smaller rolls, which can be used as raw material for further processing or sold as-is.

Slitting is commonly used in the aluminum industry to produce materials for a wide range of applications, such as automotive components, building materials, packaging, and consumer goods. The process can be performed with various grades and alloys of aluminum, depending on the specific application and desired properties of the final product.

The slitting process requires specialized equipment, such as a slitting line, which typically includes a decoiler to unwind the coil, a slitter to cut the aluminum into strips, and a recoiler to wind the strips onto smaller coils. The process is often automated to ensure consistent quality and reduce labor costs, and can be performed at high speeds to meet production demands.

How Metal Slitters Work When deciding whether to upgrade metal slitter equipment, there...

Our customers love us for our innovation, our desire to progress, and our...

The Kloeckner Metals Alpharetta branch (McFarland) is a unique flat-rolled facility. Where most...

Located in Monterrey, the Kloeckner Metals Mexico branch is unique. Unlike most competitors...

A few months ago, we welcomed our second branch in Mexico to help...

The desert is full of unique sights, happenings, and history! Gem and mineral...

The Kloeckner Metals Tulsa branch operates like a family. When someone is sick,...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: