Understanding the benefits of aluminum slitting means first understanding the value of aluminum in general. The global aluminum market is expanding fast. Experts expect to see growth from $175.85 billion in 2022 to $265.82 billion in 2030. Why such a fast growth rate, and what role do metal fabricators need to assume in this burgeoning market?

With its lightweight, corrosion-resistant properties and excellent formability, aluminum is widely used in many industries, including building and construction, transportation, and packaging. As sustainability grows in importance, industries are finding new applications for aluminum sheet from construction companies incorporating aluminum into their exterior building materials, and auto manufacturers seeing its potential for vehicle light-weighting and improved fuel-efficiency cars.

Kloeckner Metals is a full-line aluminum supplier and service center. Download this aluminum spec sheet to view what Kloeckner Metals routinely stocks.

Aluminum sheet is produced in larger coils by mills that traditionally needs to be cut down to narrower widths that are useable in the desired manufacturing process. This process is referred to as Aluminum Slitting. To meet the specific needs of various applications, aluminum coils are often slit into narrower strips, enhancing their versatility and usability.

In this guide, we explore the benefits of aluminum slitting and explain why it is such a beneficial process. We also provide a few tips to help you get the most out of your aluminum slitting projects.

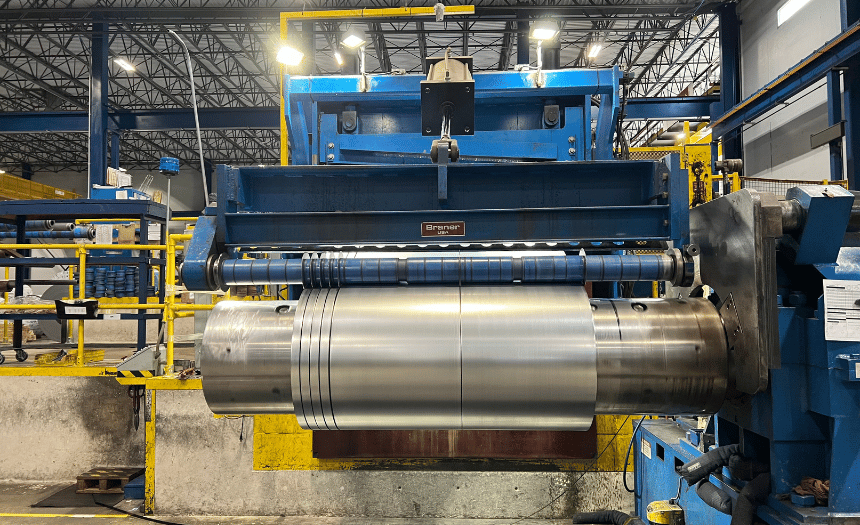

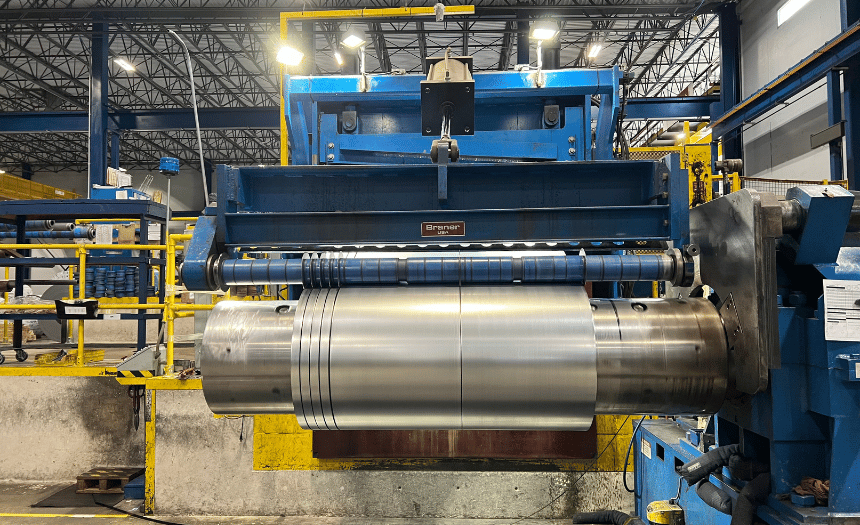

Slitting is a precise and efficient metal processing technique that is performed using specialized equipment:

Once the aluminum has been slit, it is rewound into smaller coils on individual spools for easy handling and transportation. The width of the strips is customized based on the customer’s needs.

This process helps facilitate further manufacturing and fabrication processes of aluminum sheet metal such a blanking, progressive die stamping, roll forming, tube manufacturing, to name a few. Slitting plays a crucial role in preparing coils of material for many different applications.

The aluminum slitting process is typically carried out in a dedicated facility, equipped with the machinery required for cutting and processing the metal. The process is crucial for industries that require high-precision aluminum parts and components, such as the automotive and aerospace sectors. Depending on the alloy and temper, specialized equipment may be needed.

Typical aluminum slitting capabilities

Aluminum slitting services offer a range of capabilities to cater to different requirements. These services utilize state-of-the-art slitting machines and processes to achieve precise and efficient results.

Aluminum slitting is a versatile process that can cater to a wide range of industries. Its ability to produce custom-sized coils with tight tolerances makes it an essential service for many businesses. Some of the industries that benefit from aluminum slitting include aerospace, construction, electronics, and transportation.

Aluminum coils are slit to create airplane parts such as fuel tanks, wing panels, and aircraft fuselage.

Ideal for use in harsh environments, slit aluminum strips are also used in building facades, roofing, gutters, and structural components due to their lightweight, corrosion resistance, and ease of installation.

Aluminum is an excellent conductor of electricity and helps dissipate heat efficiently, making it an essential material in the electronics industry. Industry manufacturers use slit aluminum coil to make parts that are used in electronic enclosures, heat sinks, and printed circuit boards, leveraging aluminum’s excellent conductivity and thermal properties.

Automotive manufacturers are slated to use ~50% more aluminum over the next decade. Therefore, aluminum coil slitting will continue to play a significant role in the automotive industry. Automotive manufacturers commonly use slit aluminum for manufacturing body panels, chassis components, heat shields, trim, and other structural parts. The lightweight nature of aluminum contributes to improved fuel efficiency, while its corrosion resistance ensures durability and longevity.

Slitting aluminum offers enormous benefits to manufacturers across a wide range of industries. As producers’ use of aluminum increases, expect to see precision slitting assume a larger role in sheet metal fabrication.

Kloeckner Metals is proud to offer its customer a range of benefits that together we call “The Kloeckner Advantage” including:

If you are in the market for aluminum and need aluminum slitting services, we invite you to contact us now.

Kloeckner Metals is a full-line aluminum supplier and service center. Kloeckner Metals combines a national footprint with the best fabrication and processing technologies, and innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: