AR450, or AR450F steel, is a high-carbon alloy steel great for high wear applications that’s supplied nationwide across our 40+ branches.

This is a high-carbon alloy steel that is perfect for rugged applications that require high wear resistance. It has more hardness than the AR400 steel plate with good formability, good weldability, good ductility, good strength, and good impact resistance.

This grade is an high-endurance steel with long lasting results. It withstands wear and tear while retaining a world-class surface finish. One disadvantage of this grade is that machining is not recommended.

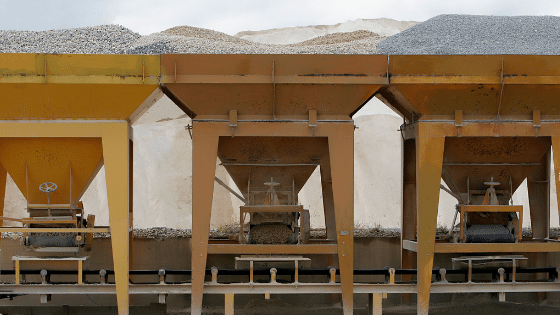

This grade is often used in the mining, architectural, recycling, and construction industries.

This grade is best for heavy wear applications. This includes construction equipment, dump body trucks, buckets, and components.

This grade is not recommended for machining

It has good weldability.

It is heat treatable.

This grade is an high-endurance steel with long lasting results. It withstands wear and tear while retaining a world-class surface finish. One disadvantage of this grade is that machining is not recommended.

This grade is often used in the mining, architectural, recycling, and construction industries.

This grade is best for heavy wear applications. This includes construction equipment, dump body trucks, buckets, and components.

This grade is not recommended for machining

It has good weldability.

It is heat treatable.

It is used where high wear resistance is needed. This includes heavy machinery found in the recycling, mining, aggregate, and construction industries.

The durability of this steel grade is directly linked to its tensile strength. High tensile strength indicates resistance to deformation. Likewise, it shows a surface hardness nearly four times that of other carbon steels.

Classifications for abrasion resistant steels correspond to their typical Brinell Hardness Number. Therefore, AR400 will have a lower hardness than AR450. However, AR400 or AR400F has better weldability than AR450 or AR450F. Another difference is that AR400 can be machined whereas AR450 is not recommended for machining.

It is used where high wear resistance is needed. This includes heavy machinery found in the recycling, mining, aggregate, and construction industries.

The durability of this steel grade is directly linked to its tensile strength. High tensile strength indicates resistance to deformation. Likewise, it shows a surface hardness nearly four times that of other carbon steels.

Classifications for abrasion resistant steels correspond to their typical Brinell Hardness Number. Therefore, AR400 will have a lower hardness than AR450. However, AR400 or AR400F has better weldability than AR450 or AR450F. Another difference is that AR400 can be machined whereas AR450 is not recommended for machining.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: