The solar industry has undergone a significant transformation by incorporating steel products into various stages of solar installations. Here is how specific steel components are used in solar projects, their applications, and the crucial metal processing techniques that contribute to the efficiency and durability of solar installations.

Did you know many of Kloeckner Metals’ nationwide branches boast special processing capabilities for the solar industry? Download our solar brochure now to see how Kloeckner Metals can service your solar needs.

Driven piles, crafted from finished steel beams of various sizes (6×7; 6×12), play a pivotal role in securing the foundations of ground-mounted and carport solar projects. These galvanized post-process piles ensure longevity and resilience against environmental factors, providing stability to the solar infrastructure.

In challenging terrains where rocky conditions prevail, earth screws become instrumental. These tubular steel components, with diameters ranging from 3 to 4 inches OD, offer a rapid installation solution, bringing stability and ease to projects grappling with harsh ground conditions.

| Materials | Finished steel beams |

| OD | 3-4″ |

| Lengths | 6×7, 6×12, various |

| Treatments | Galvanized post process |

| End use applications | Piles used in foundations of ground-mounted and carport projects to secure the racking/tracker frame to the ground; earth screws are used if the foundation must penetrate rocky terrain and can bring speed to installation |

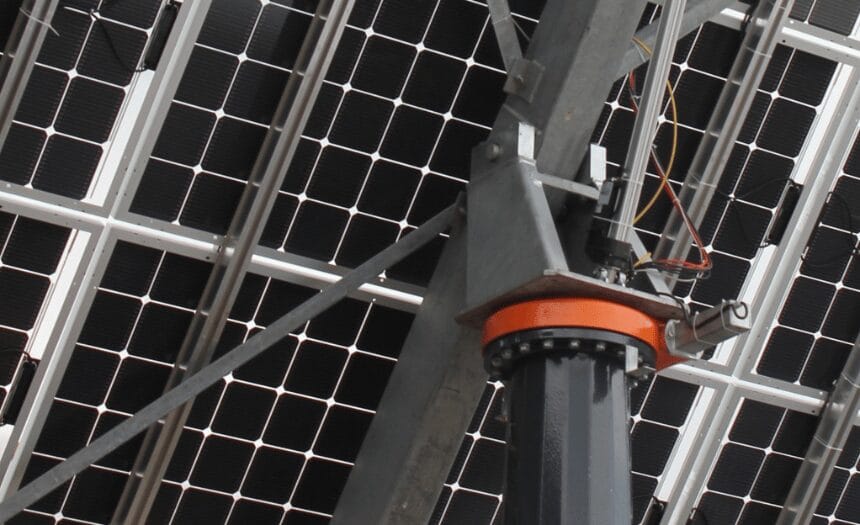

Galvanized torque tubes, available in round and square shapes, form a critical component in solar tracker systems. Ranging from 3.5 to 5 inches and typically 10-12 gauge, these tubes offer structural support for solar panels, allowing them to follow the sun’s trajectory throughout the day. Additionally, tubular products find application in some rooftop installations, securing racks to roofs efficiently.

| Materials | Round or square galvanized torque tube |

| OD | 3.5-5″ |

| Thickness | 10-12 gauge |

| Treatment | G90 coating |

| End use applications | Panels are mounted on tubes in tracker system; tube product used on some rooftops to secure the track to the roof |

Various roll-formed shapes, including rectangles, Zs, and Cs, constitute the primary structure of fixed tilt solar systems. With gauges ranging from 8 to 20 and coated with G90 to G180, these steel components provide the necessary framework for securing solar panels. Purlins and trusses play a crucial role in maintaining stability and integrity in fixed-tilt configurations.

| Materials | Roll-formed Zs and Cs |

| Thickness | 8-20 gauge |

| Treatment | G90 to G180 |

| End use applications | Frameworks for securing fixed tilt solar panels |

Finished steel beams, available in diverse sizes (6 x 7; 6 x 12), are integral to constructing carport frames supporting the solar canopy. Like other components, these beams undergo galvanization post-processing, ensuring they withstand the elements and provide a robust foundation for solar installations.

| Materials | Finished steel beams |

| Lengths | 6×7, 6×12, various |

| Treatment | Galvanized post process |

| Example use applications | Used to construct the carport frame to support the canopy |

Understanding the metal processing techniques involved is vital to appreciating the quality and reliability of steel components in solar projects. Precise metal processing techniques, such as roll forming, slitting, fabrication, and tube processing, ensure the components used in solar installations meet specific requirements and maintain structural integrity.

Roll forming is a key technique employed in shaping various steel components used in solar installations. This process ensures precision and consistency in creating profiles such as tubes, purlins, and trusses.

Slitting is crucial for producing steel strips of the required width, ensuring uniformity in the components used in solar tracker systems and other applications. Roll forming ensures precision and consistency in creating profiles such as tubes, purlins, and trusses, while slitting is crucial for producing steel strips of the required width.

Fabrication involves assembling different steel elements and creating the final components used in solar installations. This step contributes to the solar system’s overall structural integrity and performance.

Tube processing techniques, such as torque tubes, are applied to shape and refine tubular steel components. This ensures that these components meet the specific requirements for supporting solar panels in tracker systems and rooftop installations.

The solar industry relies heavily on steel products and metal processing techniques to ensure solar installations’ efficiency, durability, and versatility. Steel components such as tubes, purlins, trusses, and beams are crucial in providing foundational support and shaping the primary structures of solar installations. These components undergo steel galvanization post-processing, ensuring they can withstand the elements and provide a robust foundation for solar installations.

The collaboration between the strength of steel and the ingenuity of solar technology is paving the way for a cleaner, more sustainable future. As the solar industry continues to evolve, steel and solar technology will likely drive innovations and further advancements in sustainable energy solutions.

Did you know many of Kloeckner Metals’ nationwide branches boast special processing capabilities for the solar industry? Download our solar brochure now to see how Kloeckner Metals can service your solar needs.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The unprecedented pace of solar growth is challenging and reforming...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: