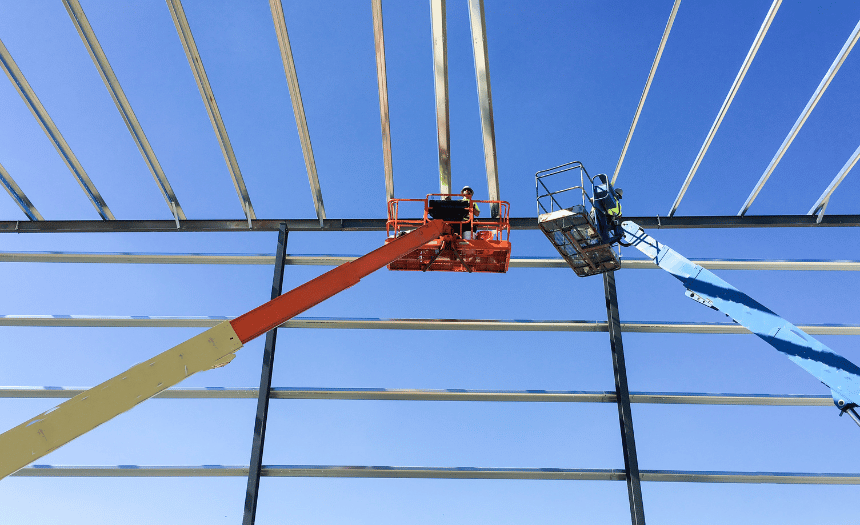

If you’ve got a roof over your head, it’s partly thanks to purlins. A purlin is the name given to one of the horizontal metal bars that support the load of the roof deck. Most often seen in metal buildings, purlins are themselves supported by rafters and walls — all critical to structural support.

Since purlins come in many sizes, materials, and costs, let’s look at what they are, what they do, the benefits they offer, and how they may fit into your project.

If you’d like to speak with an expert, contact us now. When it comes to metal roofing suppliers, Kloeckner Metals combines a national footprint with 50 years in the business.

Purlins are horizontal structural devices supporting roof decking in a metal roofing or steel frame construction. They are typically made of steel or aluminum and are installed perpendicular to the rafters or trusses.

As secondary framing components, purlins support the roof decking and distribute the load evenly across the rafters or trusses, helping prevent the roof from sagging or bowing.

Although modern metal purlins are a product of the Industrial Revolution, the use of purlin-like structures to distribute a roof’s weight dates back to ancient times when builders used heavy materials like thatch or clay to construct roofs. As technology advanced, metal purlins offered several benefits over traditional wooden supports, including strength, durability, and ease of installation.

Today, purlins come in various types, including sleeved, butted, double-span, and heavy-end bay. They are sold in markets worldwide and used by automotive, manufacturing, energy, warehouse, logistics, and commercial industries.

Purlins are an essential part of metal roofing and steel frame construction. Their specific purposes include:

Metal buildings are becoming increasingly popular as an alternative to wood buildings partly because they are more robust and durable than wood buildings, requiring less maintenance. Metal buildings, more energy-efficient than their wooden counterparts, can be recycled at the end of their lifespan.

Holding up the roof of a metal building is different, in some ways, than keeping the roof on a wooden edifice. Purlins are commonly made from steel or aluminum in metal roofing and steel frame construction. The material selection is crucial for ensuring adequate strength and durability to support the imposed loads.

Composed of materials such as steel or aluminum, metal purlins provide excellent structural support for roofs in steel frame construction. Their high strength-to-weight ratio allows for longer spans, reducing the need for intermediate supports and facilitating open, flexible architectural designs.

Metal purlins resist decay, insects, and fire, ensuring long-term structural integrity. Additionally, their installation is relatively quick and cost-effective, contributing to overall construction efficiency. With superior load-bearing capabilities and resistance to environmental factors, metal purlins are a reliable choice for ensuring stability and longevity in roofing systems.

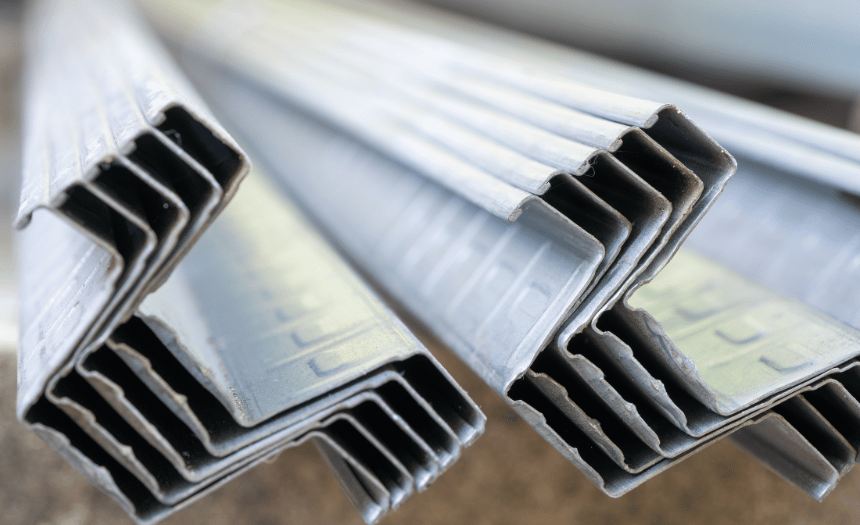

There are two main types of metal purlins: C-purlins and Z-purlins. C-purlins, the most prevalent metal type, find application across various construction scenarios. Z-purlins are stronger than C-purlins and are often used in heavy-duty applications.

Characterized by their “C” shape with flanges on each side, c-purlins are crucial in distributing loads evenly across rafters or trusses. The design of the flanges ensures effective load transfer and stability in steel frame construction. These versatile components come in various sizes and thicknesses, accommodating different structural requirements.

C-purlins are manufactured from diverse materials such as steel, aluminum, or galvanized steel, providing options to meet specific project needs. These materials’ versatility enhances corrosion resistance, durability, and overall structural performance. As a result, C-purlins stand as reliable and efficient elements, contributing to the stability and longevity of roofing systems in diverse construction applications.

Z-purlins, featuring a distinctive “Z” shape with ridges on each side, are integral to enhancing the structural strength of roofing systems. The ridges provide additional strength and facilitate secure attachment to rafters or trusses. This design contributes to the roofing structure’s overall stability and load-bearing capacity.

Similar to C-purlins, Z-purlins are available in various sizes and thicknesses, offering flexibility in design and construction. Z-purlins resist corrosion and environmental factors from steel, aluminum, and galvanized steel. Their adaptability and strength make Z-purlins a preferred choice, ensuring efficient load distribution and structural integrity in various construction projects.

When deciding between C-purlins and Z-purlins for a construction project, the choice often hinges on specific structural and design requirements. With their “C” shape and flanges on each side, C-purlins are commonly chosen for applications where effective load transfer and stability are paramount. Their versatility in accommodating various sizes and thicknesses makes them suitable for multiple projects.

In contrast, distinguished by their “Z” shape and ridges, Z-purlins provide heightened structural strength and secure attachment to rafters or trusses. The decision may depend on factors such as the required load-bearing capacity, the desired level of structural stability, and the architectural preferences of the project.

Purlins provide structural support to roofs and walls in construction. They are instrumental in distributing the roof covering load, such as metal sheets, to primary structural elements, averting overloading and ensuring stability.

Purlins commonly utilize materials like steel, aluminum, and galvanized steel, with material choice influenced by structural needs, environmental factors, and project budget.

The size and spacing of purlins depend on factors such as the type of roofing material, local building codes, and the span of the roof. Engineers and architects typically calculate these parameters based on the specific requirements of each construction project.

Purlins are crucial load-bearing members in roofing systems, and their design must consider factors like wind loads, snow loads, and other environmental forces. Engineers calculate the load-bearing capacity based on the cross-sectional shape and dimensions of the purlin, known as its sectional properties.

Cold-formed steel sections, including C or Z profiles, are often used due to their favorable strength-to-weight ratio. Engineers meticulously engineer load distribution, connection details, spacing, spans, and deflection control to ensure purlins withstand imposed loads and environmental conditions. This meticulous design approach guarantees the structural integrity of the roofing system.

Purlins are used in various construction projects, including residential and commercial buildings. While they are commonly associated with larger industrial structures, they can also support roofs in residential homes, especially in designs prioritizing open spaces and long spans.

Purlins help achieve longer spans between supports, allowing for more flexible architectural designs. Additionally, they serve as attachment points for roofing materials and facilitate the integration of insulation and services.

The benefits extend to enhanced durability, reduced maintenance, and efficient load-bearing capabilities, making purlins a valuable choice for residential projects aiming for aesthetic appeal and structural integrity.

The maintenance requirements for purlins depend on the building products used. Steel and aluminum purlins are generally durable and low-maintenance, but periodic inspections for signs of corrosion or damage are advisable. The lifespan of purlins varies based on factors like material, environmental conditions, and maintenance practices, but they are designed to provide long-term structural support in construction projects.

Standard maintenance practices for purlins depend on the material used, with steel and aluminum purlins generally being durable and low-maintenance. Periodic inspections for signs of corrosion or damage are advisable, and any issues should be addressed promptly to prevent structural compromise.

Factors influencing the lifespan of purlins include material durability, exposure to environmental conditions, and adherence to maintenance schedules. Properly designed and maintained purlins can have a significant lifespan, providing long-term structural support in construction projects while minimizing the need for extensive upkeep.

Kloeckner Metals supplies painted hot rolled and galvanized metals for a diverse range of purlins in various materials and specifications. With a customer-centric approach and a global presence, Kloeckner Metals simplifies the supply chain for roofing and metal building manufacturers, making them a trusted choice for construction projects of all scales.

If you’d like to speak with an expert, contact us now. When it comes to metal roofing suppliers, Kloeckner Metals combines a national footprint with 50 years in the business.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: