A stainless steel depot is a specialized facility or supplier that stocks and provides a wide range of stainless steel products and services. These depots serve as one-stop shops for all your stainless steel needs, offering various grades, shapes, and services that cater to a diverse customer base.

Kloeckner Metals is a full-line stainless steel supplier and service center. Download our stainless steel spec sheet today and check what Kloeckner Metals routinely stocks.

When choosing a stainless steel depot, several factors should guide your decision. Here are some key aspects to consider:

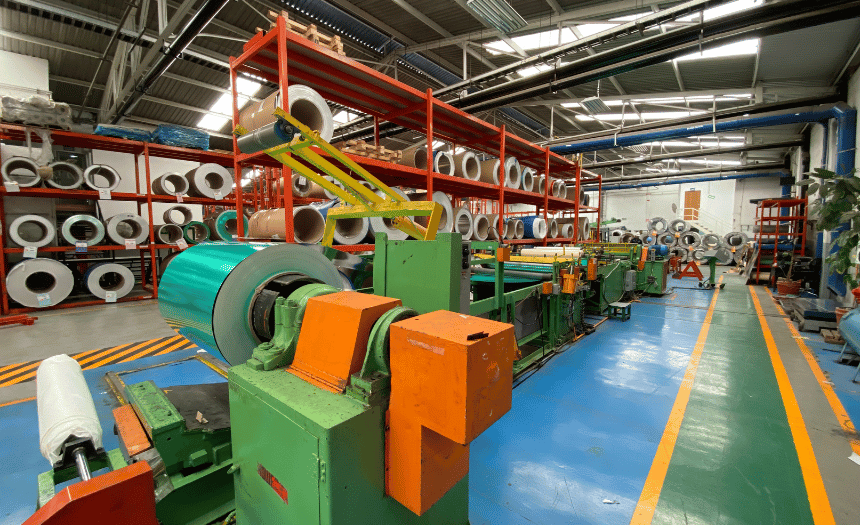

An excellent stainless steel depot should have an extensive inventory of stainless steel products. This includes various grades, shapes, and sizes of stainless steel sheets, plates, bars, and tubes. A diverse inventory ensures that you have access to the specific stainless steel products you require for your projects or clients.

Depots that offer cutting and processing services are especially valuable. Look for depots that provide slitting, blanking, shearing, and cut-to-length services. These services save you time and resources by ensuring your stainless steel materials are tailored to your project’s specifications.

Stainless steel comes in various grades, each with its unique properties. The most common grades you’ll encounter at a stainless steel depot are 304, 316, and 409 stainless steel. Choosing the right grade of stainless steel is crucial to the success of your project, and a reputable depot should be able to provide guidance on the best grade for your needs.

In addition to stainless steel sheets, it’s essential to have access to various stainless steel products, including stainless steel plates, bars, and tubes in various grades and finishes.

Stainless steel sheets are among the most commonly used forms of stainless steel, and they often require various processing services to meet specific project needs. Here are some typical services performed on stainless steel sheets at depots:

Slitting involves cutting stainless steel sheets into narrower strips or coils. This service is useful when you need stainless steel in different widths for your project. A dependable depot should offer slitting services to customize your material.

Blanking is the process of cutting out predetermined shapes or patterns from stainless steel sheets. It’s essential for creating components or parts with precise dimensions, making it a valuable service for various industries.

Shearing is the cutting of stainless steel sheets into straight-line segments. It’s used to obtain sheets of specific sizes, ensuring they meet the requirements of your project.

Cut-to-length services provide stainless steel sheets cut to your specified dimensions. This service is particularly helpful for reducing material waste and streamlining your production processes.

As mentioned earlier, stainless steel comes in a variety of grades. Here’s a closer look at some of the most common grades and their typical applications:

This is one of the most widely used stainless steel grades, known for its excellent corrosion resistance and versatility. 304/304L stainless steel includes minimum 18% chromium and 8% nickel. It’s also food-safe and can withstand temperatures up to 2,650 degrees Fahrenheit. This grade is often used to form food processing equipment, kitchen appliances, architectural trim, and construction.

Renowned for its superior corrosion resistance, 316 stainless steel is ideal for applications in harsh environments. Composed of chromium, nickel, and molybdenum, grade 316/316L stainless steel is common in marine environments, chemical processing equipment, pharmaceutical machinery, and medical devices.

409 stainless steel offers good corrosion resistance and heat resistance. Made of steel, 11% chromium, and a small amount of nickel, 409 stainless steel is not the most corrosive resistant grade but has its unique place. Automotive exhaust systems, catalytic converters, and industrial combustion chambers are often made of 409 grade stainless steel.

Stainless steel sheets come in various thicknesses and sizes. They are highly versatile and used in countless applications, from kitchen countertops to industrial machinery. Another common product, stainless steel plates, are thicker and more robust than sheets. They are often used in heavy-duty applications like construction and manufacturing equipment.

Stainless steel bars are ideal for applications where strength and durability are paramount, such as in the construction and automotive industries. Stainless steel tubes are widely used in constructing pipelines, structural supports, and fluid transport systems.

You’re in luck if you’re looking for a stainless steel depot nearby. Kloeckner Metals has a network of depots conveniently located across multiple areas. Here’s a list of our stainless steel plants:

With these locations, you will likely find a Kloeckner Metals depot ready to serve your stainless steel needs.

Stainless steel depots play a crucial role in the supply chain of this versatile material. If you’re a business seeking stainless steel for your projects, understanding what to look for in a stainless steel depot is essential. By considering factors like inventory, services, and the range of products offered, you can make informed choices that lead to the success of your projects.

Kloeckner Metals, with its network of depots across various locations, is ready to provide you with the stainless steel solutions you need. The next time you’re in the market for stainless steel, remember to choose wisely and ensure that you find a depot that meets all your requirements.

Kloeckner Metals is a full-line stainless steel supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and most innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: