American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it in sheet, plate, or foil form according to the Aluminum Association. This metal is popular across industries due to its unique properties and malleability. Most aluminum goes to buyers in the construction, transportation, and packaging industries.

Let’s delve into the specifics of aluminum metal sheets, focusing on the 3003 and 5052 grades, their manufacturing processes, processing methods, and industry applications.

Kloeckner Metals is a full-line aluminum supplier and service center. Download our aluminum spec sheet and see what Kloeckner Metals routinely stocks.

Aluminum begins as a sedimentary rock called bauxite, which has a high concentration of aluminum. Professional refiners remove the impurities from bauxite by smelting it in a large-scale electrolytic cell.

Once they have pure aluminum, the refiners cast the metal into blocks, which can be shaped and processed at aluminum rolling mills. These mills fashion raw metal into the sheets, plates, and coils manufacturers can use to create products for their customers.

Aluminum rolling mills usually hot roll aluminum sheets quite thin, making them about half as thick as plates, though they can be hot rolled thinner. Professionals at the mill cold roll the metal to improve flexibility, enhance strength, eliminate surface imperfections, and can reduce the thickness further to order specification. Mills typically impose a minimum order requirement.

The process described here is common, but it’s not universal. Some mills cold roll aluminum to make sheets. This process usually results in a stronger but more brittle material because the microstructure of the metal doesn’t change during the rolling process.

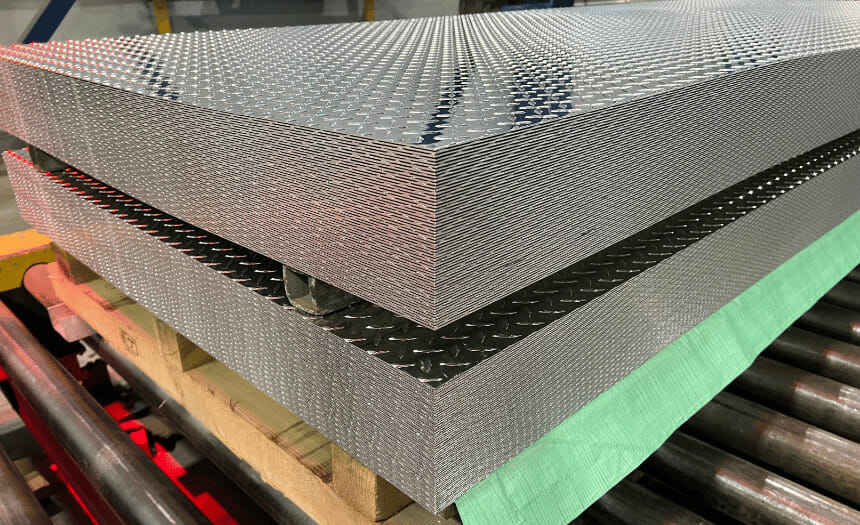

Whatever their process, mills turn out aluminum sheets in a variety of dimensions and finishes. Common thicknesses are .02″ to 2″ thick, and they can be plain or finished. Common finishes include diamond plate, checker plate, painted, unpainted, perforated, embossed, or anodized. Each size and finish has its own purpose.

For example, plain aluminum is commonly used in the construction, automotive, and automobile industries. Tread plates are often used on outdoor staircases to prevent trip-and-fall accidents, and painted aluminum can protect against weathering and corrosion.

Aluminum sheets undergo various processing methods to achieve the desired dimensions and characteristics, including:

Blanking is a process that involves cutting the aluminum sheets into specific shapes or blanks as per the requirements. Multi-blanking combines cut-to-length and slit-to-width processes. Blanking offers excellent dimensional control, accuracy, and repeatability along with straight, superior finished edges.

In coil coating, a protective coating is applied to the aluminum sheet coils to enhance durability, aesthetics, and resistance to environmental factors. Coated aluminum is commonly used in the food packaging, interior decoration, and building and construction industries.

Aluminum sheets are cut to precise lengths as needed for a particular application. The sheets can be straight cut or mitre cut.

Aluminum sheets are cut into smaller, uniform strips through a process called shearing. This process requires a punch-and-die mechanism. The punch (moving blade) pushes the aluminum against the die (fixed blade), which creates a clean tear without heating or melting the metal.

In aluminum slitting, the sheets are slit into narrower widths, enabling customization for various purposes. Slitting uses extremely sharp circular blades to make the parallel cuts.

Aluminum sheets may be assembled or kitted to form a complete package. Assembling uses an assembly-line model in which each employee performs a single task until the product is complete. Kitting is the combination of two or more metal products into a single kit. Assembly and kitting help streamline the supply chain, giving customers what they need quickly and affordably.

As the final step, the processed aluminum sheets are prepared for shipping and delivered to manufacturers and industries. Most aluminum is shipped as freight by ocean, truck, or rail. The greatest threats to any metal in transit are moisture, heat, and scratching or denting. Transit coatings can provide temporary protection for metal during shipping.

Like steel and other metals, aluminum is graded with each grade revealing the metal’s properties, values, and potential uses. Aluminum grades use a four-digit system. The first number describes the alloy. For instance, 1000 grades are pure aluminum while the 2000 series is a copper alloy and the 3000 series is a manganese alloy. The second digit indicates how the alloy is modified, and the third and fourth digits label the specific alloy.

In the aluminum sheet market, the 3003 and 5052 grades stand out as industry standards due to their distinct characteristics and applications:

The 3xxx series of aluminum is an alloy of pure aluminum and primarily manganese. Typically, that mix looks like 1.2% Mn, 0.12% Cu, and 98.6% Al. This combination makes these sheets strong, durable, and corrosion resistant. While 6xxx series may be slightly more corrosion resistant, 3xxx sheets are an affordable alternative.

Known for its excellent formability, 3003 aluminum sheets are commonly used in applications requiring moderate strength and good corrosion resistance. Industries such as packaging, automotive, and construction widely use 3003 aluminum sheets.

The 5xxx series of aluminum is an alloy of pure aluminum and magnesium. Other alloying elements typically include copper, manganese, silicon, tin, and zinc. Due to the metal’s high corrosion resistance and easy weldability, 5052 aluminum sheets are ideal for marine and aquatic applications, as well as in the aerospace industry.

Aluminum metal sheets, especially the 3003 and 5052 grades, represent pivotal components in various industries owing to their remarkable properties and versatile applications. Learn more about the difference between 3003 and 5052 aluminum.

Understanding the manufacturing processes and processing methods is essential in harnessing the full potential of aluminum metal sheets in diverse sectors. With its corrosion-resistance, light weight, and durability, aluminum is fast becoming a major metal product in a wide array of industries. To find out more about what grade, size, and finish you need for your aluminum sheets, contact us at Kloeckner Metals.

Kloeckner Metals is a full-line aluminum supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and most innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: