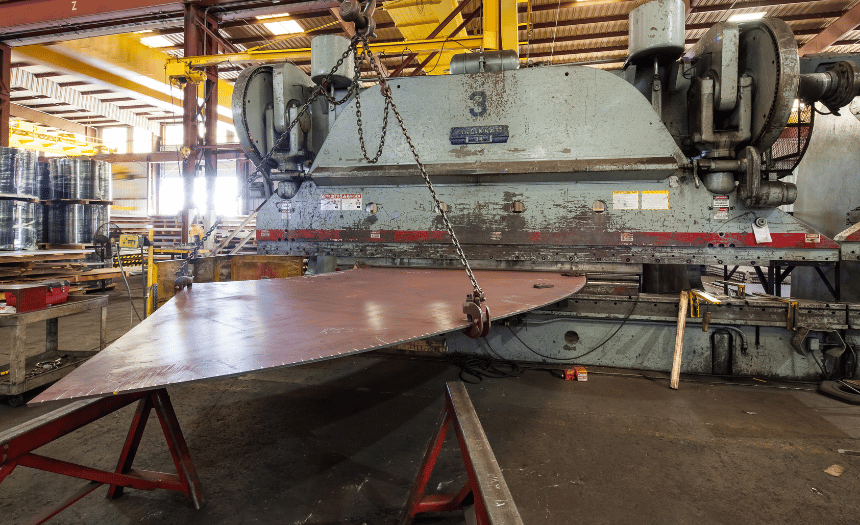

Kloeckner Metals is proud to offer our customers a 500 ton press brake for the bending and shaping of metal sheets and plates.

Answer:

A 500-ton press brake is a heavy-duty machine used in the metalworking industry to bend and shape metal sheets or plates. This type of press brake is capable of applying a tremendous amount of force, up to 500 tons or 1,000,000 pounds, to bend thick and heavy metal sheets or plates with a wide range of dimensions and shapes.

The specific dimensions and thicknesses of metal that can be bent on a 500-ton press brake depend on the machine’s characteristics, such as the size of the bed, stroke, and throat depth. This machine is commonly used in industries that require the production of large and complex metal parts and components, such as aerospace, automotive, construction, and heavy machinery.

The precision and accuracy of a 500-ton press brake make it a reliable and efficient machine for bending metal sheets or plates with high precision and repeatability. It is a versatile machine that can handle a wide range of metal types, including carbon steel, aluminum, and stainless steel, and is designed to operate efficiently in high-volume production environments.

Overall, it is an essential machine for metal fabrication businesses that require a heavy-duty press brake capable of bending large and thick metal sheets or plates with precision and accuracy.

Answer:

There are several benefits, including:

Overall, a 500-ton press brake offers a combination of high bending capacity, precision, versatility, efficiency, and productivity, which makes it an ideal choice for metalworking applications that require heavy-duty bending and high precision. It is a powerful machine that can handle thick and large metal parts and components with high precision and accuracy, making it a valuable investment for metal fabrication businesses.

What is a 500-ton press brake?

Answer:

A 500-ton press brake is a heavy-duty machine used in the metalworking industry to bend and shape metal sheets or plates. This type of press brake is capable of applying a tremendous amount of force, up to 500 tons or 1,000,000 pounds, to bend thick and heavy metal sheets or plates with a wide range of dimensions and shapes.

The specific dimensions and thicknesses of metal that can be bent on a 500-ton press brake depend on the machine’s characteristics, such as the size of the bed, stroke, and throat depth. This machine is commonly used in industries that require the production of large and complex metal parts and components, such as aerospace, automotive, construction, and heavy machinery.

The precision and accuracy of a 500-ton press brake make it a reliable and efficient machine for bending metal sheets or plates with high precision and repeatability. It is a versatile machine that can handle a wide range of metal types, including carbon steel, aluminum, and stainless steel, and is designed to operate efficiently in high-volume production environments.

Overall, it is an essential machine for metal fabrication businesses that require a heavy-duty press brake capable of bending large and thick metal sheets or plates with precision and accuracy.

What are the benefits of a 500-ton press brake?

Answer:

There are several benefits, including:

Overall, a 500-ton press brake offers a combination of high bending capacity, precision, versatility, efficiency, and productivity, which makes it an ideal choice for metalworking applications that require heavy-duty bending and high precision. It is a powerful machine that can handle thick and large metal parts and components with high precision and accuracy, making it a valuable investment for metal fabrication businesses.

Today is my birthday. So what better way to celebrate than to talk...

The main benefit of Kloeckner Metals Santa Fe Springs’ new 52-foot Cincinnati Press...

This past year, Kloeckner Metals’ Santa Fe Springs Branch upgraded their facility with...

There are infinite possibilities for automotive aluminum sheet. With thousands of car parts...

When starting a new commercial or residential project, you will want the right...

What is a Metal Service Center? First things first, what is a metal...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: