Kloeckner Metals is proud to carry punch presses, sometimes called punching presses, throughout our network of 40+ North American branches.

Answer:

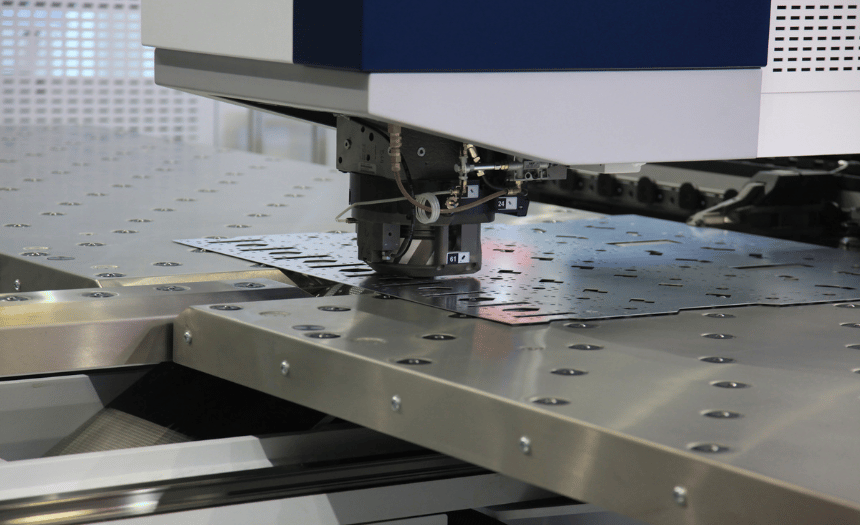

A punch press is a type of machine press that is used to cut, form, or shape a variety of metals, including carbon steel, stainless steel, and aluminum, using a punch and die. It is typically composed of a bed, a ram, and a motor that drives the ram up and down. The material to be cut or formed is placed on the bed, and the punch and die are positioned above it. When the motor is activated, the ram moves downward, exerting a force on the punch and die, which cuts or forms the material.

There are different types of punch press, such as mechanical, hydraulic, and pneumatic punch press. They can be used for a variety of operations such as punching, shearing, bending, coining, embossing, and more. They are widely used in manufacturing industries such as metalworking, plastics, and woodworking.

They can be controlled manually or by a computer numerical control (CNC) which allows for a high degree of automation and precision. It is a versatile machine that can be used for a wide range of applications, from simple cutting and punching to complex forming and shaping operations.

Answer:

There are several benefits, including:

Overall, the benefits include high speed, cost-effectiveness, precision, versatility, consistency, automation, and safety. They are widely used in metalworking and fabrication operations for their ability to produce accurate, high-quality parts efficiently and cost-effectively.

What is a punch press?

Answer:

A punch press is a type of machine press that is used to cut, form, or shape a variety of metals, including carbon steel, stainless steel, and aluminum, using a punch and die. It is typically composed of a bed, a ram, and a motor that drives the ram up and down. The material to be cut or formed is placed on the bed, and the punch and die are positioned above it. When the motor is activated, the ram moves downward, exerting a force on the punch and die, which cuts or forms the material.

There are different types of punch press, such as mechanical, hydraulic, and pneumatic punch press. They can be used for a variety of operations such as punching, shearing, bending, coining, embossing, and more. They are widely used in manufacturing industries such as metalworking, plastics, and woodworking.

They can be controlled manually or by a computer numerical control (CNC) which allows for a high degree of automation and precision. It is a versatile machine that can be used for a wide range of applications, from simple cutting and punching to complex forming and shaping operations.

What are the benefits of a punch press?

Answer:

There are several benefits, including:

Overall, the benefits include high speed, cost-effectiveness, precision, versatility, consistency, automation, and safety. They are widely used in metalworking and fabrication operations for their ability to produce accurate, high-quality parts efficiently and cost-effectively.

Patty Heidenrich is the Sales Manager at California Steel & Tube. She started...

Aluminum is no doubt one of the most popular metals, shaping the capabilities...

Solar energy runs on metal. Copper, silver, zinc, aluminum, and (of course) steel...

Lightweighting, a concept in the automotive industry, demands that all car parts be...

Structural steel shapes provide support to buildings of all kinds. They’re integral to...

Since stainless steel is aesthetically pleasing and corrosion resistant, it’s often used in...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: