High speed coil coated products (also referred to as prepainted products) can be a significant aid in a company’s environmental, efficiency, and bottom-line cost reduction road to the future. Coil coating dates back to the 1930s and is employed worldwide today.

Kloeckner Metals, with assistance via its Coil Coated Services Group, can provide a path to improvements whether (a) fine tuning a current coil coating users incoming product or (b) managing a post paint-to-prepaint conversion project. Coil coated products can be aesthetic and functional in nature.

The industries we can serve are almost unlimited, however we currently serve the following industries with products engineered specifically to fit their respective needs: automotive – transit, appliance – large & small, agricultural equipment, building products, boats, clean rooms, cold storage structures, walk-in and reach-in coolers, elevators & escalators, food & beverage, garage door panels and opener shells, general metal cabinetry and shells, HVAC, utility trailers, and Tonneau covers.

Kloeckner is proud to offer our clients the best in coil coating equipment and capabilities. Let our experts help with all of your coil coating needs.

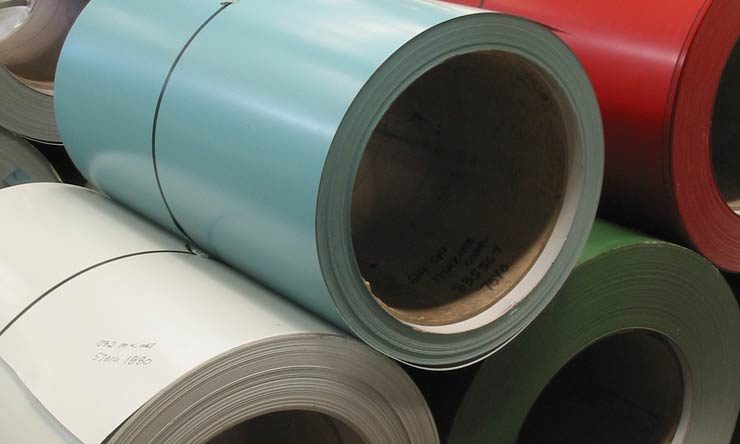

Because coil coating is a high-speed process, we employ large coils (or rolls) of various metal types which are commonly cleaned, pretreated, and coated on both sides of the flat rolled strip. When a primer and a topcoat are both necessary to meet the end use needs, both the primer and the topcoat is applied in the same single pass through the coil coating line in most cases. This makes large to medium quantities of a single decimal thickness, width, and paint technology combination a very efficient means with which to deliver a finish coated product to the next processing point.

The coil coated product can have a finished product surface that is ready for slitting to width, embossing, cutting-to-length or other applicable fabrication. As all the steps in coil coating are performed on a flat strip the integrity of the cleanliness of the base metal surface and the adhesion of each layer is optimal and the adhesion integrity promotes all function performance including, but not limited to, corrosion resistance.

The metals that we currently have coil coated on a regular basis are aluminum, cold rolled steel, electro-galvanized steel, galvalume™, hot dipped galvanized steel, hot rolled steel, stainless steel, and tin plate.

Answer:

Coil coating is a process that involves the continuous application of a decorative and protective layer of paint onto a metal strip (typically aluminum coil or steel). The metal strip is first cleaned and treated to improve adhesion, then passed through a series of rollers that apply primer, color coats, and clear protective layers. The result is a coil of metal with a uniform, high-quality finish that can be used in a variety of applications, including construction (e.g., roofing and siding), appliances, and consumer goods. The process offers several advantages over other methods of applying paint, including increased efficiency, improved color consistency, and reduced waste.

Answer:

The following equipment is typically used in the process:

In addition to these core pieces of equipment, there may also be additional auxiliary equipment used in the process, such as slitting machines, edge trimming equipment, or tension leveling equipment. The specific equipment used will depend on the type of coating being applied, the desired output, and the size of the metal coils being processed.

What is coil coating?

Answer:

Coil coating is a process that involves the continuous application of a decorative and protective layer of paint onto a metal strip (typically aluminum coil or steel). The metal strip is first cleaned and treated to improve adhesion, then passed through a series of rollers that apply primer, color coats, and clear protective layers. The result is a coil of metal with a uniform, high-quality finish that can be used in a variety of applications, including construction (e.g., roofing and siding), appliances, and consumer goods. The process offers several advantages over other methods of applying paint, including increased efficiency, improved color consistency, and reduced waste.

What equipment is used?

Answer:

The following equipment is typically used in the process:

In addition to these core pieces of equipment, there may also be additional auxiliary equipment used in the process, such as slitting machines, edge trimming equipment, or tension leveling equipment. The specific equipment used will depend on the type of coating being applied, the desired output, and the size of the metal coils being processed.

Coil coating refers to the process of creating prepainted steel and aluminum. Prepainted...

Chromium Stainless Steel plays a unique role in metallurgy. Stainless steels are first...

As a painted coil distributor, selling building materials requires a unique set of...

Aaron Small, Director of Coil Coated Services at Kloeckner Metals, discusses changes ,...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: