Kloeckner Metals is proud to offer multi-blanking and pass along the benefits of increased efficiency, cost savings, and accuracy to our customers.

Answer:

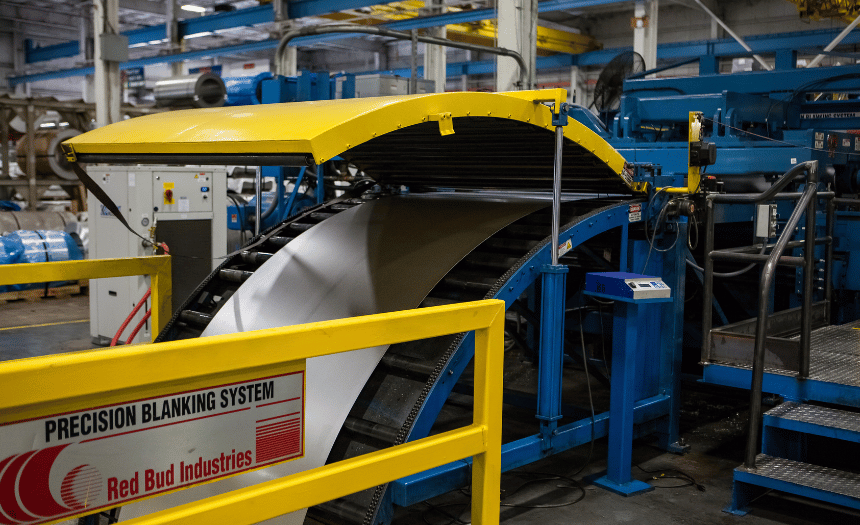

Multi-blanking is a metal processing technique that involves cutting large metal coils into smaller blanks of specific sizes. The process involves making multiple cuts in a single pass to create several blanks from a single sheet or coil of metal.

Multi-blanking typically involves using a combination of cutting methods, such as shearing, slitting, and/or laser cutting, to produce high-precision blanks of different shapes and sizes. The resulting blanks can then be used in various manufacturing and fabrication applications, such as stamping, deep drawing, and roll forming.

The advantages include increased efficiency, cost savings, consistency and accuracy, flexibility, and improved productivity. Multi-blanking is widely used in industries such as automotive, appliance manufacturing, construction, and aerospace, where high-quality and uniform metal blanks are required for efficient and cost-effective production.

Overall, multi-blanking is an important metal processing technique that helps to optimize the use of raw materials, increase productivity, and improve the quality and consistency of metal products.

Answer:

Multi-blanking offers several benefits in the metal processing industry, including:

Overall, multi-blanking is a cost-effective and efficient method for producing high-quality metal blanks of various shapes and sizes, which is widely used in the metal processing industry.

What is multi-blanking?

Answer:

Multi-blanking is a metal processing technique that involves cutting large metal coils into smaller blanks of specific sizes. The process involves making multiple cuts in a single pass to create several blanks from a single sheet or coil of metal.

Multi-blanking typically involves using a combination of cutting methods, such as shearing, slitting, and/or laser cutting, to produce high-precision blanks of different shapes and sizes. The resulting blanks can then be used in various manufacturing and fabrication applications, such as stamping, deep drawing, and roll forming.

The advantages include increased efficiency, cost savings, consistency and accuracy, flexibility, and improved productivity. Multi-blanking is widely used in industries such as automotive, appliance manufacturing, construction, and aerospace, where high-quality and uniform metal blanks are required for efficient and cost-effective production.

Overall, multi-blanking is an important metal processing technique that helps to optimize the use of raw materials, increase productivity, and improve the quality and consistency of metal products.

What are the benefits of multi-blanking?

Answer:

Multi-blanking offers several benefits in the metal processing industry, including:

Overall, multi-blanking is a cost-effective and efficient method for producing high-quality metal blanks of various shapes and sizes, which is widely used in the metal processing industry.

The desert is full of unique sights, happenings, and history! Gem and mineral...

Reports indicate that as demand in the automotive and construction sectors continues to...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: