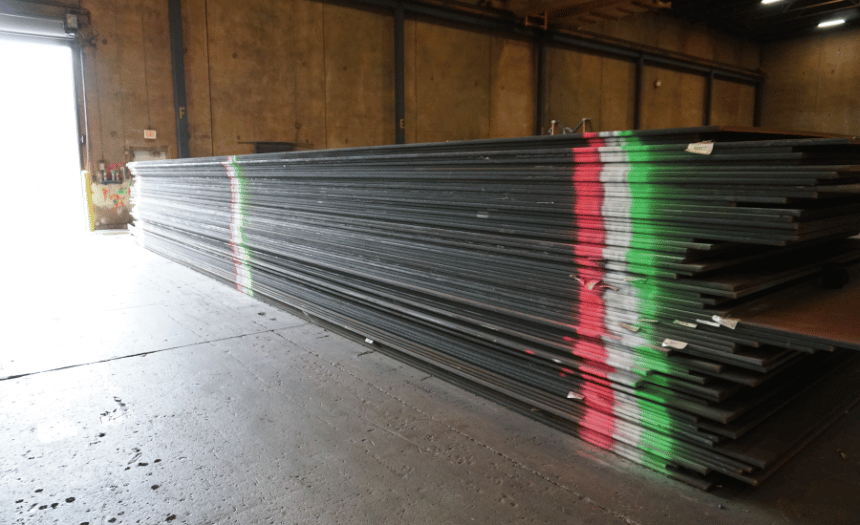

Kloeckner Metals carries a flattener 96″ capable of flattening sheet metal, strip metal, and coil metal, removing warping or distortion so that metal becomes flat and even in thickness.

Answer:

In the metals industry, a flattener is a machine that is used to flatten sheet metal, strip metal, or coil metal. The process of flattening involves removing any warping or distortion in the metal, so that it becomes flat and even in thickness.

A flattener typically consists of a series of rollers that are designed to apply pressure to the metal as it passes through the machine. The rollers can be arranged in different configurations, depending on the type of metal being flattened and the specific requirements of the application.

The purpose of a flattener is to produce flat, uniform sheet metal, strip metal, or coil metal that is free from any warping or distortion. This is important in many industries, including automotive, aerospace, construction, and fabrication, where dimensional accuracy and consistency are critical.

Flatteners are commonly used in conjunction with other metalworking equipment, such as cut-to-length lines, slitting lines, and roll forming machines. They can be used to flatten a wide variety of metal types, including carbon steel, stainless steel, and aluminum.

Answer:

A flattener, stretcher, precision, and corrective leveler are all used in the metals industry to produce flat sheet metal, but they work in different ways and are suited for different applications.

A flattener is a machine that is designed to remove any warping or distortion in sheet metal, strip metal, or coil metal, and to produce a flat and uniform surface. It typically uses a series of rollers to apply pressure to the metal as it passes through the machine. Flattening is a general process that can be used on a wide variety of metal types.

A stretcher leveler is a machine that is designed to stretch the metal along its length, producing a flat and stress-free sheet of metal with a high degree of flatness and dimensional stability. It is typically used on thicker gauge materials, ranging from 1/8 inch to 1 inch thick, and can be used on a variety of metal types, including steel, aluminum, and stainless steel.

A precision leveler is a machine that is designed to level metal that has not yet been warped or distorted. It uses rollers to gradually and precisely flatten the metal to a desired level of flatness, without inducing any new warping or distortion. Precision levelers are often used for high-precision applications where flatness is critical, such as in the aerospace, electronics, and medical industries.

A corrective leveler is a machine that is designed to correct metal that has already been produced with some degree of warping or distortion. It uses a series of rollers to bend the metal in the opposite direction of the existing distortion, effectively flattening it out. Corrective levelers are often used for materials that have been damaged or have undergone thermal processing.

In summary, while flattener, stretcher, precision, and corrective leveler all produce flat sheet metal, they have different capabilities and are suited for different types of materials and applications. A flattener is a general-purpose machine for removing warping or distortion from sheet metal, while stretcher, precision, and corrective levelers are designed for specific purposes such as producing flat, stress-free sheet metal, or correcting existing warping or distortion in metal.

What is a flattener in the metals industry?

Answer:

In the metals industry, a flattener is a machine that is used to flatten sheet metal, strip metal, or coil metal. The process of flattening involves removing any warping or distortion in the metal, so that it becomes flat and even in thickness.

A flattener typically consists of a series of rollers that are designed to apply pressure to the metal as it passes through the machine. The rollers can be arranged in different configurations, depending on the type of metal being flattened and the specific requirements of the application.

The purpose of a flattener is to produce flat, uniform sheet metal, strip metal, or coil metal that is free from any warping or distortion. This is important in many industries, including automotive, aerospace, construction, and fabrication, where dimensional accuracy and consistency are critical.

Flatteners are commonly used in conjunction with other metalworking equipment, such as cut-to-length lines, slitting lines, and roll forming machines. They can be used to flatten a wide variety of metal types, including carbon steel, stainless steel, and aluminum.

How is a flattener different than a stretcher, precision, or corrective leveler?

Answer:

A flattener, stretcher, precision, and corrective leveler are all used in the metals industry to produce flat sheet metal, but they work in different ways and are suited for different applications.

A flattener is a machine that is designed to remove any warping or distortion in sheet metal, strip metal, or coil metal, and to produce a flat and uniform surface. It typically uses a series of rollers to apply pressure to the metal as it passes through the machine. Flattening is a general process that can be used on a wide variety of metal types.

A stretcher leveler is a machine that is designed to stretch the metal along its length, producing a flat and stress-free sheet of metal with a high degree of flatness and dimensional stability. It is typically used on thicker gauge materials, ranging from 1/8 inch to 1 inch thick, and can be used on a variety of metal types, including steel, aluminum, and stainless steel.

A precision leveler is a machine that is designed to level metal that has not yet been warped or distorted. It uses rollers to gradually and precisely flatten the metal to a desired level of flatness, without inducing any new warping or distortion. Precision levelers are often used for high-precision applications where flatness is critical, such as in the aerospace, electronics, and medical industries.

A corrective leveler is a machine that is designed to correct metal that has already been produced with some degree of warping or distortion. It uses a series of rollers to bend the metal in the opposite direction of the existing distortion, effectively flattening it out. Corrective levelers are often used for materials that have been damaged or have undergone thermal processing.

In summary, while flattener, stretcher, precision, and corrective leveler all produce flat sheet metal, they have different capabilities and are suited for different types of materials and applications. A flattener is a general-purpose machine for removing warping or distortion from sheet metal, while stretcher, precision, and corrective levelers are designed for specific purposes such as producing flat, stress-free sheet metal, or correcting existing warping or distortion in metal.

When starting a new commercial or residential project, you will want the right...

Aluminum is no doubt one of the most popular metals, shaping the capabilities...

Metal is used in all kinds of environments, including applications with high exposure...

Annealing is a specific process of heat treatment that alters the properties of...

Since stainless steel is aesthetically pleasing and corrosion resistant, it’s often used in...

Humans are harnessing the wind’s energy with wind turbines, windmills, and other technologies...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: