Kloeckner Metals is proud to stock G235, G115, G65, and G90 galvanized steel.

G115, G65, G235, and G90 galvanized steels have been cold rolled and placed in a zinc bath for improved corrosion resistance, making it especially suitable for outdoor applications. The weight of the zinc coating is indicated by the number following the G. For example, G90 indicates that the zinc coating is 0.9 oz/ft one of the most popular galvanized steel carbon flat roll products available. G90 and G65 tend to do better in higher moisture environments, and G115 and G235 are mainly reserved for specific applications requiring a thicker zinc coating. All of these galvanized steel grades are used in the solar industry, architecture industry, and HVAC industry among others.

These hot dip galvanized steel grades are intended for applications requiring corrosion resistance and moderate bending and forming capabilities.

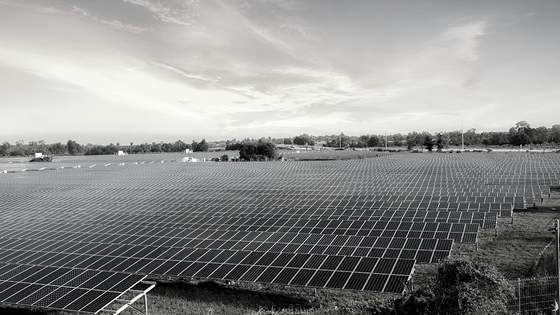

These grades are seen widely across the solar industry. You’ll also see these galvanized steel grades in the architectural, and construction industries.

Applications with galvanized steel include transmission poles, wind turbines, solar panels, architectural and ornamental components, and HVAC systems.

These galvanized steel grades are easy to machine. Bending, forming, and cutting are all easy due to the steel’s malleable nature.

Welding for these galvanized steel grades is excellent.

These hot dip galvanized steel grades are intended for applications requiring corrosion resistance and moderate bending and forming capabilities.

These grades are seen widely across the solar industry. You’ll also see these galvanized steel grades in the architectural, and construction industries.

Applications with galvanized steel include transmission poles, wind turbines, solar panels, architectural and ornamental components, and HVAC systems.

These galvanized steel grades are easy to machine. Bending, forming, and cutting are all easy due to the steel’s malleable nature.

Welding for these galvanized steel grades is excellent.

ANSWER:

G90 galvanized steel refers to the coating type and the weight of the coating layer that has been applied to the steel. ‘G’ tell us that the coating is galvanized (zinc coated). The number ‘90’ indicates the weight of the zinc applied to the steel. Manufacturers measure the coating weight using the unit ounces per square foot (oz/ft2). Therefore, G90 simply means that the two-sided zinc-coating on the steel weighs 0.90 ounces per square foot.

ANSWER:

Yes. G90, G115, G65, and G235 are used in the solar industry.

ANSWER:

Galvanized steel has been cold rolled before it is placed into a zinc bath. Cold rolled steel is a mill process. Steel is passed through high pressure rollers at room temperature. This process results in a refined surface finishing character and improves durability. While the cold rolling process permits fabricators greater control and consistency to achieve ideal surface quality and thickness throughout, it tends to be a more extensive process, especially when compared to hot rolling steel.

ANSWER:

Galvanization is the process of exposing metal to a zinc bath. All galvanized steels have a protective zinc coating, that varies in weight depending on the galvanized steel grade selected. The standard guideline equates a heavier coating with higher durability.

ANSWER:

G90 galvanized steel refers to the coating type and the weight of the coating layer that has been applied to the steel. ‘G’ tell us that the coating is galvanized (zinc coated). The number ‘90’ indicates the weight of the zinc applied to the steel. Manufacturers measure the coating weight using the unit ounces per square foot (oz/ft2). Therefore, G90 simply means that the two-sided zinc-coating on the steel weighs 0.90 ounces per square foot.

ANSWER:

Yes. G90, G115, G65, and G235 are used in the solar industry.

ANSWER:

Galvanized steel has been cold rolled before it is placed into a zinc bath. Cold rolled steel is a mill process. Steel is passed through high pressure rollers at room temperature. This process results in a refined surface finishing character and improves durability. While the cold rolling process permits fabricators greater control and consistency to achieve ideal surface quality and thickness throughout, it tends to be a more extensive process, especially when compared to hot rolling steel.

ANSWER:

Galvanization is the process of exposing metal to a zinc bath. All galvanized steels have a protective zinc coating, that varies in weight depending on the galvanized steel grade selected. The standard guideline equates a heavier coating with higher durability.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: