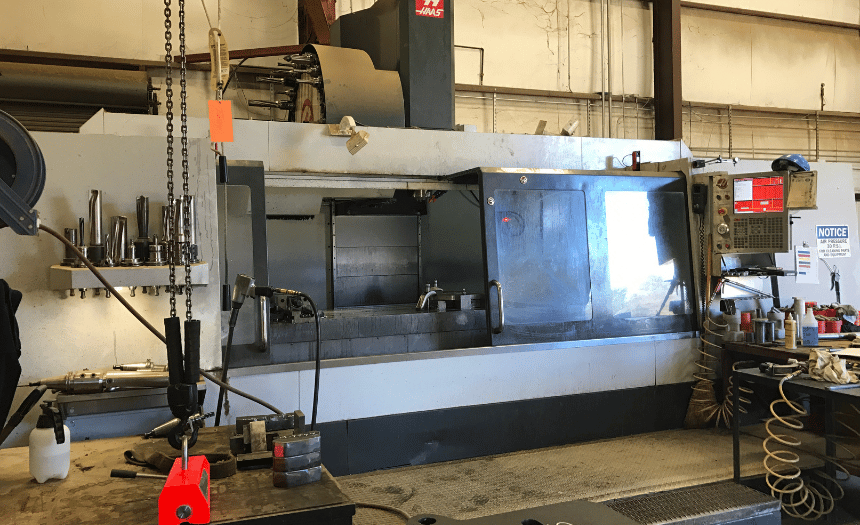

Our vertical machining centers are typically capable of beveling, drilling, and tapping metals to our customers’ precise specifications.

Answer:

A vertical machining center (VMC) can process a variety of metal types in different forms, including:

The specific type of metal and the machining process required will determine the appropriate cutting tools, speeds, and feeds to use on the VMC.

Answer:

Carbon steel is a common type of metal that is frequently processed on a vertical machining center (VMC). The most commonly processed carbon steel grades on a VMC are:

The specific carbon steel grade used will depend on the application and the required mechanical properties of the final product. Machining carbon steel on a VMC typically requires the use of carbide cutting tools, and the appropriate cutting speeds, feeds, and coolant to achieve the desired finish and accuracy.

What metal types are processed by a vertical machining center?

Answer:

A vertical machining center (VMC) can process a variety of metal types in different forms, including:

The specific type of metal and the machining process required will determine the appropriate cutting tools, speeds, and feeds to use on the VMC.

What are the most common carbon steel grades processed on a vertical machining center?

Answer:

Carbon steel is a common type of metal that is frequently processed on a vertical machining center (VMC). The most commonly processed carbon steel grades on a VMC are:

The specific carbon steel grade used will depend on the application and the required mechanical properties of the final product. Machining carbon steel on a VMC typically requires the use of carbide cutting tools, and the appropriate cutting speeds, feeds, and coolant to achieve the desired finish and accuracy.

We are pleased to share our steel and aluminum metals reference guides that...

The American Society for Testing and Materials (ASTM) A36 and the American Society...

To calculate the weight of a steel plate, you need to answer a...

When getting to know the different types of steel beams, what’s important to...

Steel beams—like h beams, w beams, and s beams—support heavy loads. In fact,...

Structural steel is one of the most widely used materials in commercial and...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: