When getting to know the different types of steel beams, what’s important to look out for?

Beams are a structural steel shape designed to carry heavy loads with supports at two points or more. However, even seemingly slight geometric differences impact how well beams will bear weight and resist bending or buckling.

Kloeckner Metals is a full-line steel supplier and service center. Click to download our structural spec sheet and check what Kloeckner Metals routinely stocks.

So, it’s good to have an idea of the different types of steel beams to better understand when and why a structural engineer will choose one beam type over another. First, let’s take a look at how steel beams are made.

There are two primary ways to fabricate steel beams: welding and hot rolling.

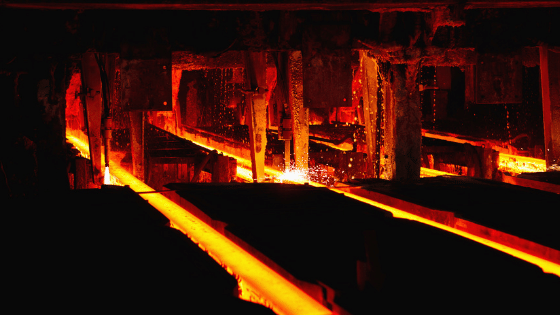

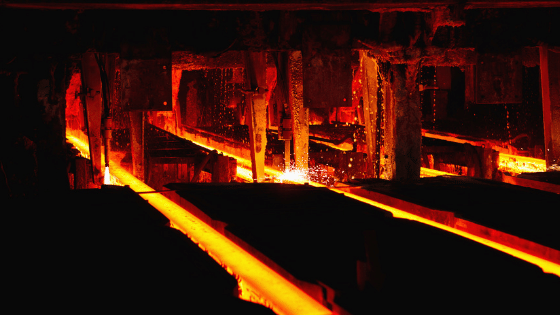

Beams are a hot rolled structural steel product. Steel resists shaping when it’s cold. So, the first step in making steel beams is to heat the steel. To do this, steel goes through a furnace with automatic burner control systems to maintain target temperatures, utilizing complex computer programs.

The actual rolling is a process made possible with profile mill stands that form the intended cross section. Through a combination of motors and mounted bearings, the steel is passed through large rollers configured in such a way as to form the desired beam shape. These forces regularly exceed thousands of tons, and because the steel is so hot, it easily passes through. The steel is then closely monitored as it cools to ensure that the integrity of the microstructures is maintained. Additional processes, like hot dip galvanizing, can be applied to further protect the steel.

Different types of steel beams can also be assembled by welding separate structural steel plates together. In this way, each flange is attached to the web separately. Welding can decrease the weight of the beam, and add strength. This is how plate girders are made. They are welded, bolted or riveted to form unique dimensions. For instance, plate girders might have a deep vertical web and narrower flanges.

Structural steel fabricators can bend, cut, weld, and assemble the metal to precise sizes and dimensions. Steel beam sizes and thicknesses will depend both on the type of steel beam being manufactured, and the exact requirements for the specific building application.

The basic materials for steel beam fabrication include high-quality structural steel made from metal grades that satisfy structural steel standards set by the American Institute of Steel Construction (AISC) and the appropriate equipment, tools, and techniques to properly execute engineering diagrams.

Metal fabricators must be experienced enough to follow engineering diagrams and blueprints and have a working knowledge of the latest fabrication software, equipment, and safety standards in order to produce quality beam fabrication. Click to read more about structural steel fabrication.

Types of steel beams have different sizes. Generally, beams have a width, height, and length and are measured by their weight in pounds per foot. And, to account for a variety of building needs, many metal fabricators offer custom cut-to-length fabrication services.

When getting to know the different types of beam sizes keep an eye out for their starting widths.

A992

A572-50:

A36:

A709-50:

A529-50:

In addition to structural steel, beams can be formed out of aluminum through the process of extrusion. Kloeckner supplies aluminum beam in 6061 aluminum. Unlike carbon steel beams, 6061 aluminum beam is often seen in the automotive industry.

This chart lays out some of the different types of beams, including I-beams, S-beams, W-beams, H-beams, M-beams, T- beams, and plate girders. It’s possible you may have heard the I-beam referred to as the universal beam, so we’ve included some other common names these beams go by as well.

| Beam Type | Key Characteristics | Advantages |

| I-beams

(Universal beam, Universal Column) |

|

|

| S-beams

(S-section, American Standard Beams)

|

|

|

| W-beams

(Wide Flange Beam)

|

|

|

|

H-beams (H Piles , HP beams, bearing piles) |

|

|

| M-beams

(miscellaneous shapes) |

|

|

| T-beams

(WT, ST) |

|

|

| Plate Girders |

|

|

This is truly just the beginning of getting to know the different types of steel beams. Please reach out to our team with any questions you have about beam fabrication processes, or if you need help determining which beam type or metal grade is best suited for your desired application.

Kloeckner Metals is a full-line steel supplier and service center catering to different types of steel beams. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies along with the most innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: