Kloeckner offers an extensive range of metal grating products such as 19W4 serrated bar grating, 19W4 non-serrated bar grating, and expanded metal grating.

| Bearing Bars | Size Ranges | |||

|---|---|---|---|---|

| Available In | ||||

| 1 x 1/8 | Type 19W4 | 24" x 240" 24" x 288" | Painted & Galvanized | ||

| 1 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Painted & Galvanized | ||

| 1 - 1/4 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Painted & Galvanized | ||

| 1 - 1/2 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Painted & Galvanized | ||

| Bearing Bars | Size Ranges | |||

|---|---|---|---|---|

| Available In | ||||

| 1 x 1/8 | Type 19W4 | 24" x 240" 24" x 288" | Bare, Painted & Galvanized | ||

| 1 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Bare, Painted & Galvanized | ||

| 1 - 1/4 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Bare, Painted & Galvanized | ||

| 1 - 1/2 - 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Bare, Painted & Galvanized | ||

| Style | Weight Pounds per in Hundred C.S.F. | |||

|---|---|---|---|---|

| Size Ranges | ||||

| 3 lb. | 300 | 48" x 96" | ||

| 4 lb. | 400 | 48" x 96" | ||

| 4.27 | 427 | 48" x 96" | ||

| 5 lb. | 500 | 48" x 96" | ||

Metal grating is a type of metal structure made by welding equally distanced bearing bars with cross bars. These steel bars intersect with each other perpendicularly to form a platform that looks similar to a grid. These structures are easily fabricated, and known for their strength and durability.

Metal grating is a key part of the industrial flooring and construction industry. It is used in fences, walkways, and platforms on job-sites and in support for walls and structures in construction. There are three sub-groups of metal grating: non-serrated grating, serrated grating, and expanded metal grating.

Type 19W4 serrated bar grating has notches in the bearing bars. This provides traction for large automobiles and forklifts in environments with water and oil.

Type 19W4 non-serrated grating has a smooth surface on its bearing bars and cross bars. It is used for areas of traffic with heavy automobiles and forklifts.

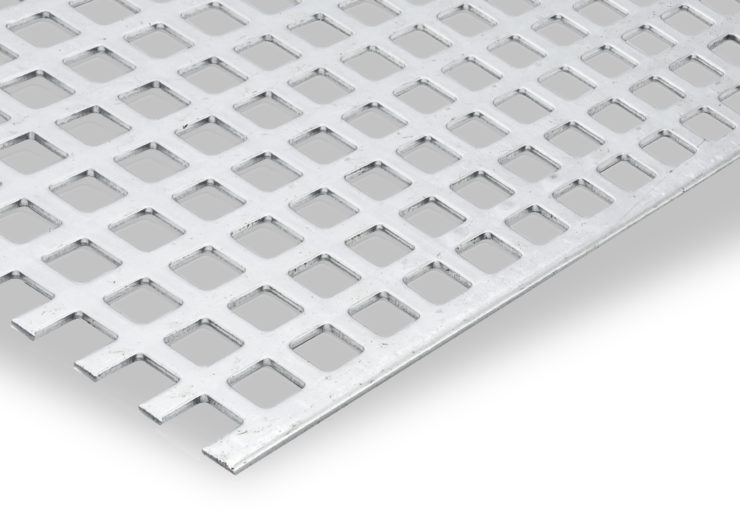

Expanded metal grating is sheets of metal cut and stretched to form a diamond shape pattern that is similar to a mesh net or web. The metal is never completely cut so it is able to retain its strength. Expanded metal grating can be used in construction to support materials in walls or structures.

Type 19W4 serrated bar grating has notches in the bearing bars. This provides traction for large automobiles and forklifts in environments with water and oil.

Type 19W4 non-serrated grating has a smooth surface on its bearing bars and cross bars. It is used for areas of traffic with heavy automobiles and forklifts.

Expanded metal grating is sheets of metal cut and stretched to form a diamond shape pattern that is similar to a mesh net or web. The metal is never completely cut so it is able to retain its strength. Expanded metal grating can be used in construction to support materials in walls or structures.

ANSWER:

The standard sizes of metal bar grating include 19W4 and 19W2 bar grating, 15W4 and 15W2 bar grating, and 11W4 and 11W2 bar grating. The standard sizes for expanded metal grating include 3lb, 4lb, 4.27lb, and 5lb.

ANSWER:

Metal grating is often used for industrial flooring in factories or for safety in pedestrian walkways depending on the grade and type of metal grating.

ANSWER:

Metal bar grating is made by welding bearing bars and cross bars together to form a grid. Expanded metal grating is formed by stretching and cutting diamond shapes into a sheet of metal, forming what looks like a metal net or web.

ANSWER:

Bar grating welds bearing bars with perpendicular cross bars used for industrial style flooring Metal grating is similar to expanded metal grating and can be used for safety in pedestrian walkways, stairs, bridges etc. All bar grating is metal grating, but not all metal grating is bar grating.

ANSWER:

Non-serrated bar grating has a smooth surface on the bearing and cross bars while serrated bar grating has notches on the bars surface that help with traction and skid resistance.

ANSWER:

19W4 refers to the amount of space between the crossbars and the width between the bearing bars. The W4 in 19W4 refers to the width of 4 inches in between each crossbar. The width between the bearing bars is 1-3/16 inches and the 19 represents this width when looking at metal grating.

ANSWER:

Expanded metal grating is offered in different weights so that it can withstand varying amounts of pressure. Heavier weights may be used in pathways for large vehicles, while lighter weights may be used for pedestrian walkways.

ANSWER:

The standard sizes of metal bar grating include 19W4 and 19W2 bar grating, 15W4 and 15W2 bar grating, and 11W4 and 11W2 bar grating. The standard sizes for expanded metal grating include 3lb, 4lb, 4.27lb, and 5lb.

ANSWER:

Metal grating is often used for industrial flooring in factories or for safety in pedestrian walkways depending on the grade and type of metal grating.

ANSWER:

Metal bar grating is made by welding bearing bars and cross bars together to form a grid. Expanded metal grating is formed by stretching and cutting diamond shapes into a sheet of metal, forming what looks like a metal net or web.

ANSWER:

Bar grating welds bearing bars with perpendicular cross bars used for industrial style flooring Metal grating is similar to expanded metal grating and can be used for safety in pedestrian walkways, stairs, bridges etc. All bar grating is metal grating, but not all metal grating is bar grating.

ANSWER:

Non-serrated bar grating has a smooth surface on the bearing and cross bars while serrated bar grating has notches on the bars surface that help with traction and skid resistance.

ANSWER:

19W4 refers to the amount of space between the crossbars and the width between the bearing bars. The W4 in 19W4 refers to the width of 4 inches in between each crossbar. The width between the bearing bars is 1-3/16 inches and the 19 represents this width when looking at metal grating.

ANSWER:

Expanded metal grating is offered in different weights so that it can withstand varying amounts of pressure. Heavier weights may be used in pathways for large vehicles, while lighter weights may be used for pedestrian walkways.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: