There are three types of expanded metals — standard expanded metal, flattened expanded metal, and expanded metal grating. Kloeckner stocks all of them.

| Style | Weight Pounds per in Hundred C.S.F. | |||

|---|---|---|---|---|

| Size Ranges | ||||

| 3 lb. | 300 | 48" x 96" | ||

| 4 lb. | 400 | 48" x 96" | ||

| 4.27 | 427 | 48" x 96" | ||

| 5 lb. | 500 | 48" x 96" | ||

| Size (inches) | Style No. | Size Ranges | |||

|---|---|---|---|---|

| 1/2 | #16 | 48" x 96" | |||

| 1/2 | #13 | 48" x 96" | |||

| 3/4 | #9 | 48" x 96" | |||

| Size (inches) | Style No. | Size Ranges | |||

|---|---|---|---|---|

| 1/2 | #16 | 48" x 96" | |||

| 1/2 | #13 | 48" x 96" | |||

| 3/4 | #9 | 48" x 96" | |||

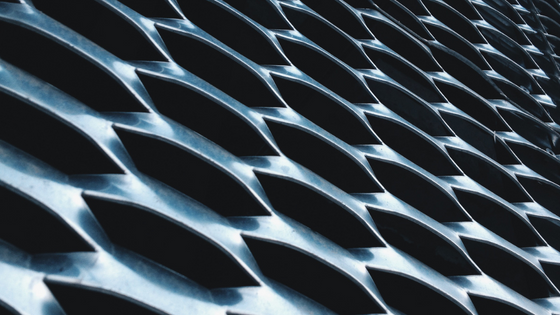

Standard expanded metal is formed from a single sheet of pressed metal that has been die-cut. It features sharp angles and maintains maximum flexibility. To create expanded metal grating, manufacturers run a sheet of metal through rollers with sharp, saw-like blades. These blades expand and flatten it.

Flattened expanded metal is about 5% lighter than the standard version. Flattening expanded metal involves heating a sheet of metal until it’s soft and then putting pressure on it while it cools. Rollers in a press, weights on top of a flat plate, or both can be used for flattening expanded metal.

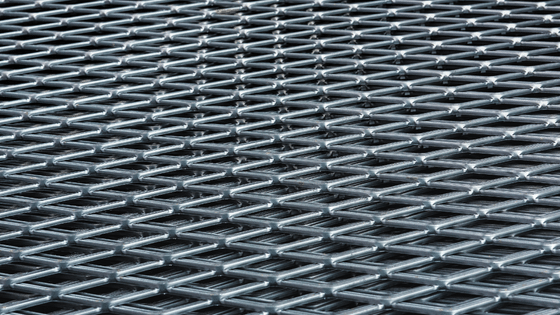

Expanded metal grating is sometimes referred to as open wire mesh because it has openings between each piece of wire.

Standard expanded metal is formed from a single sheet of pressed metal that has been die-cut. It features sharp angles and maintains maximum flexibility. To create expanded metal grating, manufacturers run a sheet of metal through rollers with sharp, saw-like blades. These blades expand and flatten it.

Flattened expanded metal is about 5% lighter than the standard version. Flattening expanded metal involves heating a sheet of metal until it’s soft and then putting pressure on it while it cools. Rollers in a press, weights on top of a flat plate, or both can be used for flattening expanded metal.

Expanded metal grating is sometimes referred to as open wire mesh because it has openings between each piece of wire.

Expanded metal grating is one of the strongest, most versatile, and most widely used all-purpose materials available today. From industrial, agricultural, and commercial applications to traditional consumer uses such as shower doors and pet barriers, expanded metal grating can be found just about everywhere you look.

All expanded metal retains its open design when it’s flattened. It can be used for decorative purposes or to keep debris out of openings too small for it to pass through. Expanded metal usually comes with a protective coating that keeps it from rusting.

Expanded metal offers many advantages, including flexibility, lower costs, and lightweight strength.

One disadvantage of expanded metal, however, is that it may feature several sharp edges that need to be sanded down to prevent injuries.

Since its early days as a construction material, expanded metal has become a staple in many industries. Due to its low cost and durability, expanded metal is still used by these industries today, including:

Expanded metal is used for many commercial and industrial applications, including ventilation, noise reduction, security, and fire prevention. Consider each of these applications in turn:

Fire Prevention: Expanded metal mesh often forms fire pits, cookers and grills, blast detectors, fire escapes, and ground support equipment.

Manufacturers create expanded metal with a special machine that turns sheet metal into mesh. The machine simultaneously stretches and cuts the metal to form the uniform holes that give the mesh its unique characteristic. Once fashioned, the metal can be cut into sheets or wound into coils.

Some companies choose not to weld their expanded metal after machining because they want its surface roughness to retain its original open texture. Other companies, though, do weld their mesh metal because they need the extra strength. Still others use combinations of welding and cutting techniques.

When dealing with expanded metal, there are two methods of heat treating: controlled thermal expansion and flame-cutting.

Controlled thermal expansion involves heating the metal until it is soft, then controlling its cooling rate via water spray or forced air.

Flame-cutting expands metal by applying a blowtorch directly to it. Expanded metals that have been subjected to either of these heat treatments are referred to as corrugated expanded metals.

Expanded metal offers many advantages, including flexibility, lower costs, and lightweight strength.

One disadvantage of expanded metal, however, is that it may feature several sharp edges that need to be sanded down to prevent injuries.

Since its early days as a construction material, expanded metal has become a staple in many industries. Due to its low cost and durability, expanded metal is still used by these industries today, including:

Expanded metal is used for many commercial and industrial applications, including ventilation, noise reduction, security, and fire prevention. Consider each of these applications in turn:

Fire Prevention: Expanded metal mesh often forms fire pits, cookers and grills, blast detectors, fire escapes, and ground support equipment.

Manufacturers create expanded metal with a special machine that turns sheet metal into mesh. The machine simultaneously stretches and cuts the metal to form the uniform holes that give the mesh its unique characteristic. Once fashioned, the metal can be cut into sheets or wound into coils.

Some companies choose not to weld their expanded metal after machining because they want its surface roughness to retain its original open texture. Other companies, though, do weld their mesh metal because they need the extra strength. Still others use combinations of welding and cutting techniques.

When dealing with expanded metal, there are two methods of heat treating: controlled thermal expansion and flame-cutting.

Controlled thermal expansion involves heating the metal until it is soft, then controlling its cooling rate via water spray or forced air.

Flame-cutting expands metal by applying a blowtorch directly to it. Expanded metals that have been subjected to either of these heat treatments are referred to as corrugated expanded metals.

ANSWER:

Standard expanded metal sheets are usually either 4 x 8 or 6 x 12 feet. They are heavier, thicker, and denser than flattened expanded metal.

Flattened expanded metal is measured by Strand Width (SWDT), Strand Thickness (STK), Longway Aperture (LWA), and Shortway Aperture (SWA). This type of grating has a flatter surface than standard expanded metal, which allows it to be more rigid while also maintaining the same strength.

Due to its relatively narrow width, flattened expanded metal is often used as racking or shelving in retail stores and warehouses due to its ability to support a heavy load over a small surface area.

ANSWER

Standard expanded metal is used in many horizontal installations. Common uses include walkways, a/c security mesh, sidewalk grates, and truck/cab dividers.

One of the many benefits of expanded metal is its ability to be easily installed into place. Simply fasten it with screws or nails in your desired location and it will hold firm—it’s that simple! As long as you don’t try to bend or twist it out of shape while installing, there’s no need for clamps or special tools during installation.

ANSWER:

Standard expanded metal sizes refer to the size of the holes in the mesh, the number of holes, the width of the metal, the metal’s length, and its thickness.

Flattened expanded metal sizes are typically available in smaller sizes since they are flattened and can be cut down to any size. If you need larger expanded metal sizes, you can look into purchasing special-order materials.

ANSWER:

Yes, 4 x 8 is a standard size. However, expanded metal comes in sheets of various sizes. Contact us at Kloeckner Metals to discuss your specific needs.

ANSWER:

Expanded metal mesh is a type of security grating that is usually made out of sheet metal tightly wrapped around an expanded wire. The result is a strong and sturdy covering for walls, walkways, or any other structures you want to keep safe.

ANSWER:

Standard expanded metal sheets are usually either 4 x 8 or 6 x 12 feet. They are heavier, thicker, and denser than flattened expanded metal.

Flattened expanded metal is measured by Strand Width (SWDT), Strand Thickness (STK), Longway Aperture (LWA), and Shortway Aperture (SWA). This type of grating has a flatter surface than standard expanded metal, which allows it to be more rigid while also maintaining the same strength.

Due to its relatively narrow width, flattened expanded metal is often used as racking or shelving in retail stores and warehouses due to its ability to support a heavy load over a small surface area.

ANSWER

Standard expanded metal is used in many horizontal installations. Common uses include walkways, a/c security mesh, sidewalk grates, and truck/cab dividers.

One of the many benefits of expanded metal is its ability to be easily installed into place. Simply fasten it with screws or nails in your desired location and it will hold firm—it’s that simple! As long as you don’t try to bend or twist it out of shape while installing, there’s no need for clamps or special tools during installation.

ANSWER:

Standard expanded metal sizes refer to the size of the holes in the mesh, the number of holes, the width of the metal, the metal’s length, and its thickness.

Flattened expanded metal sizes are typically available in smaller sizes since they are flattened and can be cut down to any size. If you need larger expanded metal sizes, you can look into purchasing special-order materials.

ANSWER:

Yes, 4 x 8 is a standard size. However, expanded metal comes in sheets of various sizes. Contact us at Kloeckner Metals to discuss your specific needs.

ANSWER:

Expanded metal mesh is a type of security grating that is usually made out of sheet metal tightly wrapped around an expanded wire. The result is a strong and sturdy covering for walls, walkways, or any other structures you want to keep safe.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: