Kloeckner offers 19W4 serrated and non-serrated bar grating in a range of sizes including bare, painted, and galvanized options.

| Bearing Bars | Size Ranges | |||

|---|---|---|---|---|

| Available In | ||||

| 1 x 1/8 | Type 19W4 | 24" x 240" 24" x 288" | Painted & Galvanized | ||

| 1 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Painted & Galvanized | ||

| 1 - 1/4 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Painted & Galvanized | ||

| 1 - 1/2 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Painted & Galvanized | ||

| Bearing Bars | Size Ranges | |||

|---|---|---|---|---|

| Available In | ||||

| 1 x 1/8 | Type 19W4 | 24" x 240" 24" x 288" | Bare, Painted & Galvanized | ||

| 1 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Bare, Painted & Galvanized | ||

| 1 - 1/4 x 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Bare, Painted & Galvanized | ||

| 1 - 1/2 - 3/16 | Type 19W4 | 24" x 240" 24" x 288" | Bare, Painted & Galvanized | ||

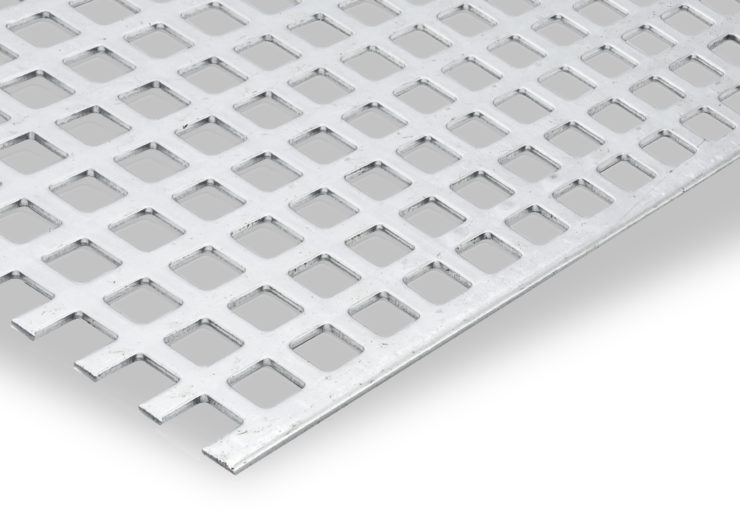

Bar grating is a type of grating that consists of bars and spaces between them. If you can think about a latticework of steel bars intersecting with each other, that’s a good way to visualize bar grating.

Bar grating is an extremely versatile material used in a variety of applications, though it’s perhaps best known as the material commonly used in chain-link fencing. Bar grating comes in two forms: serrated and non-serrated.

The purpose of serrated bar grating is to prevent vertical movement in addition to preventing lateral movement. Non-serrated grating lacks the scalloped surface that serrated grating features, and it maintains a higher load-bearing capacity.

Kloeckner regularly stocks serrated bar grating type 19W4 in the following options:

1 x ⅛ , 1 x 3/16, 1 ¼ x 3/16, 1 ½ x 3/16 Bearing Bars

24” x 240” & 24 x 288” Size Ranges

Painted & Galvanized

Non-serrated grating has same bearing bars and size ranges, but comes in bare, painted, and galvanized options.

Serrated grating offers a particular advantage when used on stairs or escalators where it tends to be less prone to slipping than non-serrated models. On busy paths and walkways, an anti-slip design is essential for preventing accidents and injuries.

However, serrated grating is easier to install and remove than non-serrated alternatives. If you’re looking for something that’s both secure and quick to swap out, serrated grating may be a good option for your venue or business.

Overall Bar Grating Advantages:

Overall Bar Grating Disadvantages:

Commercial sectors that commonly employ steel grating include marine and oil rigs, food and beverage processing, and factories and manufacturing plants.

Both serrated and non-serrated grating have a variety of applications, including industrial, residential, and commercial uses.

The construction industry uses serrated grating in areas that require secure footing, yet need to be able to provide some give in case people trip or a heavy object falls against it. For example, many fire escapes and ladders employ serrated bar grating on both sides of handrails. Another example would be anywhere an open balcony needs a secure but soft railing surface that won’t break under pressure (i.e., on cruise ships).

Landscapers often use serrated bar grating for wood decks or as fencing around trees and garden beds. It is especially popular in outdoor settings due to its weatherproof design and ease of use throughout all seasons.

Serrated grating is made in two ways, both of which are pretty simple to achieve.

1) Serrated grating can be created via machining, which involves running a saw along a bar-shaped piece of metal until its edges become knife-like in appearance although the result is not sharp like a blade. When formed this way, bar grating can be locked, riveted, or welded.

2) Perforated steel sheets can be stretched to create diamond-shaped openings between threads of steel. This is sometimes called “expanded metal” rather than bar grating.

Bar grating is easy to weld. In fact, to function properly as stair treads, platforms, or flooring, bar grating must be locked, riveted, swaged, pressure-locked, or welded in order to connect bearing bars and cross bars.

Fusing the bars through welding creates the rigidity and strength required for the product to function. Plus, welding is the most economical option. That said, welding forms a permanent joint while locking does not.

Welding serrated grating requires more precision and skill but produces a consistent, accurate end product that lasts far longer than its counterparts.

Non-serrated grating is sometimes subjected to heat treatment to increase its hardness and durability. Generally, heat treatment requires a temperature range between 772 and 1382 degrees Fahrenheit for a set amount of time (usually an hour). Serrated bar grating also requires a certain level of rigidity, but it doesn’t need to be as hard as non-serrated grating.

Serrated grating offers a particular advantage when used on stairs or escalators where it tends to be less prone to slipping than non-serrated models. On busy paths and walkways, an anti-slip design is essential for preventing accidents and injuries.

However, serrated grating is easier to install and remove than non-serrated alternatives. If you’re looking for something that’s both secure and quick to swap out, serrated grating may be a good option for your venue or business.

Overall Bar Grating Advantages:

Overall Bar Grating Disadvantages:

Commercial sectors that commonly employ steel grating include marine and oil rigs, food and beverage processing, and factories and manufacturing plants.

Both serrated and non-serrated grating have a variety of applications, including industrial, residential, and commercial uses.

The construction industry uses serrated grating in areas that require secure footing, yet need to be able to provide some give in case people trip or a heavy object falls against it. For example, many fire escapes and ladders employ serrated bar grating on both sides of handrails. Another example would be anywhere an open balcony needs a secure but soft railing surface that won’t break under pressure (i.e., on cruise ships).

Landscapers often use serrated bar grating for wood decks or as fencing around trees and garden beds. It is especially popular in outdoor settings due to its weatherproof design and ease of use throughout all seasons.

Serrated grating is made in two ways, both of which are pretty simple to achieve.

1) Serrated grating can be created via machining, which involves running a saw along a bar-shaped piece of metal until its edges become knife-like in appearance although the result is not sharp like a blade. When formed this way, bar grating can be locked, riveted, or welded.

2) Perforated steel sheets can be stretched to create diamond-shaped openings between threads of steel. This is sometimes called “expanded metal” rather than bar grating.

Bar grating is easy to weld. In fact, to function properly as stair treads, platforms, or flooring, bar grating must be locked, riveted, swaged, pressure-locked, or welded in order to connect bearing bars and cross bars.

Fusing the bars through welding creates the rigidity and strength required for the product to function. Plus, welding is the most economical option. That said, welding forms a permanent joint while locking does not.

Welding serrated grating requires more precision and skill but produces a consistent, accurate end product that lasts far longer than its counterparts.

Non-serrated grating is sometimes subjected to heat treatment to increase its hardness and durability. Generally, heat treatment requires a temperature range between 772 and 1382 degrees Fahrenheit for a set amount of time (usually an hour). Serrated bar grating also requires a certain level of rigidity, but it doesn’t need to be as hard as non-serrated grating.

ANSWER:

Steel bar grating can be serrated, basically scalloped on top, or non-serrated, simply flat on top. Serrated bars often look nicer because serrations make it more difficult for debris to accumulate and help your grating surface cleaner looking over time—but non-serrated grating is generally much cheaper than its serrated counterpart, while also being easier

ANSWER:

Bar grating is commonly available as 1 x ⅛ , 1 x 3/16, 1 ¼ x 3/16, 1 ½ x 3/16 bearing bars with size ranges 24” x 240” & 24 x 288”. If you’re using it for food safety purposes, you may need FDA approved plastic coating to cover the metal.

ANSWER:

Both stainless steel and galvanized steel gratings are coated with an anti-slip substrate to help give traction. But galvanized steel provides much tougher protection against rust and corrosion. Galvanized steel is also usually cheaper than stainless steel, but it is not able to bear as much weight.

ANSWER:

Bar grating dimensions are measured using the length of the bearing bar, the depth of the bearing bar, and the width of the cross bar. Therefore, 19W4 means the bearing bar is 1 3/16″ (19/16″) at the center. The bar is welded (W), and the cross bars are spaced at 4”.

ANSWER:

Steel bar grating can be serrated, basically scalloped on top, or non-serrated, simply flat on top. Serrated bars often look nicer because serrations make it more difficult for debris to accumulate and help your grating surface cleaner looking over time—but non-serrated grating is generally much cheaper than its serrated counterpart, while also being easier

ANSWER:

Bar grating is commonly available as 1 x ⅛ , 1 x 3/16, 1 ¼ x 3/16, 1 ½ x 3/16 bearing bars with size ranges 24” x 240” & 24 x 288”. If you’re using it for food safety purposes, you may need FDA approved plastic coating to cover the metal.

ANSWER:

Both stainless steel and galvanized steel gratings are coated with an anti-slip substrate to help give traction. But galvanized steel provides much tougher protection against rust and corrosion. Galvanized steel is also usually cheaper than stainless steel, but it is not able to bear as much weight.

ANSWER:

Bar grating dimensions are measured using the length of the bearing bar, the depth of the bearing bar, and the width of the cross bar. Therefore, 19W4 means the bearing bar is 1 3/16″ (19/16″) at the center. The bar is welded (W), and the cross bars are spaced at 4”.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: