Once an aluminum alloy is formed, what’s next for the raw material? It might be extruded aluminum. Read on to learn more about what are aluminum extrusions and how it allows aluminum to take on a multitude of shapes and purposes.

Kloeckner Metals is a full-line aluminum supplier and service center. Download our aluminum spec sheet and check what Kloeckner Metals routinely stocks.

Aluminum extrusions are the byproduct of heating aluminum material and pushing it through a die. An aluminum billet is heated to a high temperature – around 900°F – then loaded into an extrusion press. Once a ram applies pressure to it, the raw material is sent through the die to produce a shaped form. You might say that it’s like sending Play-Doh through a press that produces unique shapes.

Once the raw aluminum has been pushed through the die, it cools and hardens. It can then be cut into the desired lengths for the finished product.

Aluminum alloys from the 6xxx series tend to lend themselves well to the process of extrusion. Three alloys in particular show up in extrusion applications.

6005 Aluminum

6005 aluminum can be used in designs that require a high resistance to corrosion and moderate strength. This alloy contains significant amounts of silicon, which reduces its melting temperature and improves its ability to be extruded. 6005 also has bending properties, which make it not the best choice for applications that may be subject to overload or impact.

6005 aluminum extrusions appear in tubing, automotive connectors, ladders, and structural applications.

6063 Aluminum

6063 aluminum is widely used in extrusions because it offers a high-quality finish and corrosion resistance. Its electrical conductivity makes it a great choice for electrical tubing and applications.

6063 aluminum alloy is used for custom and standard aluminum extrusion design, as well as for structural pipes and tubes, seamless tubing, heat-sinks and much more. It shows up in end products such as window and door frames, irrigational system pipe and tube, handrails and furniture, and electrical conduits.

6463 Aluminum

Made from approximately 98% raw aluminum and small amounts of copper, iron, magnesium, manganese, silicon, and zinc, 6463 aluminum offers high density and yield strength. It is used most often in applications for architecture or construction. Aluminum extrusions made from 6463 work well for bars, tubes, rods, wire and other types of custom profiles.

Because of its light weight and malleability, aluminum finds itself well suited to a variety of applications that require hollow or complex shapes.

According to the Aluminum Extruders Council, there are a number of benefits to aluminum that is extruded, some of which include:

In addition, tooling for extruded aluminum requires generally short lead times, so products can be brought to market more quickly.

Extruded aluminum finds its way into a diverse set of industries, including:

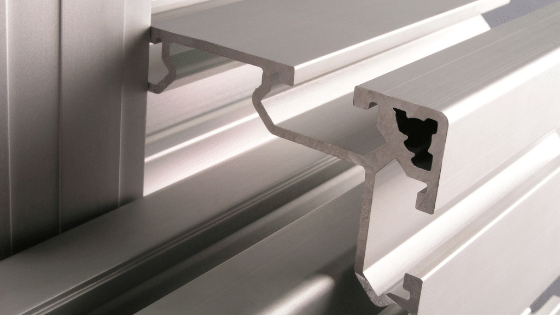

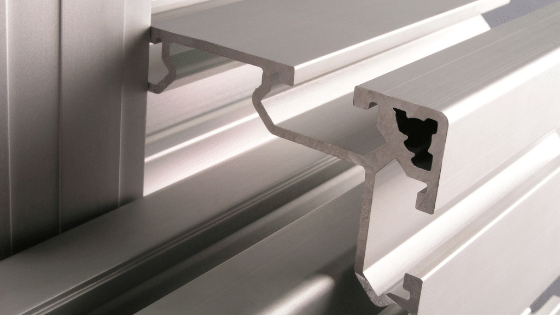

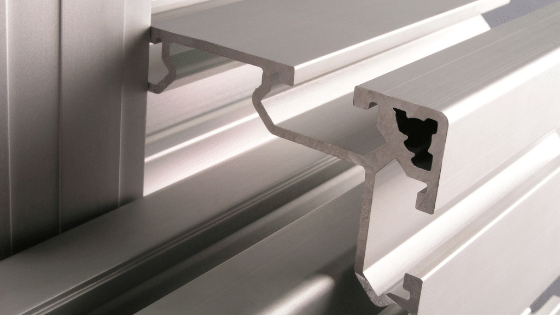

Aluminum extrusions can be formed into solid, semi-hollow, or hollow shapes. The aluminum extrusion molding apparatus has been compared with a cake decorating kit. A star tip on the pastry tube produces star-shaped frosting, and a flower tip creates a flower pattern. The extrusion process is much the same. Aluminum that is extruded, with the help of dies and hydraulic presses, can be formed into a variety of standard and custom shapes.

Here are a few standard aluminum extrusion shapes:

Aluminum channels are forms of aluminum that have a hollow center and varying wall thicknesses. There are a variety of aluminum channel styles available. Common shapes include C channels, Z channels, and U channels. Other categories include slide track channels, hat channels, nut channels, and architectural aluminum channels.

With t-slot aluminum extrusion shapes, there is a t-shaped track of negative space that allows pieces to interlock and secure in place without the need to weld or attach joints. Once in place, fasteners, nuts, locks, and other items can be used to keep the pieces together to form a modular build.

Sometimes referred to an “erector set,” 80/20 shapes allow end users to construct their own projects using T-slot aluminum extrusions.

Aluminum extrusion frames are just that; they provide a metal framework for industrial projects and equipment. They’re typically created from t-slot aluminum shapes.

Aluminum extruded tubes are a hollow, linear aluminum product. They can be cylindrical, square, or rectangular. Extruded aluminum tubing finds its way into applications such as railings, window frames, and other architectural products.

Kloeckner Metals is a full-line aluminum supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and most innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: