In the fast-paced automotive industry, precision and efficiency are key factors that drive success. One crucial process that plays a pivotal role in achieving these goals is aluminum blanking. Blanking allows for the most efficient utilization of sheet material and facilitates forming of components that would be otherwise impossible.

Let’s delve into the world of aluminum blanking, its significance in the automotive sector, and the factors automotive manufacturers should consider when partnering with first-stage metal processors. Join us as we explore the ins and outs of aluminum blanking and its impact on automotive innovation.

Kloeckner Metals is a full-line aluminum supplier and service center. Download our aluminum spec sheet to see what’s in stock at Kloeckner Metals.

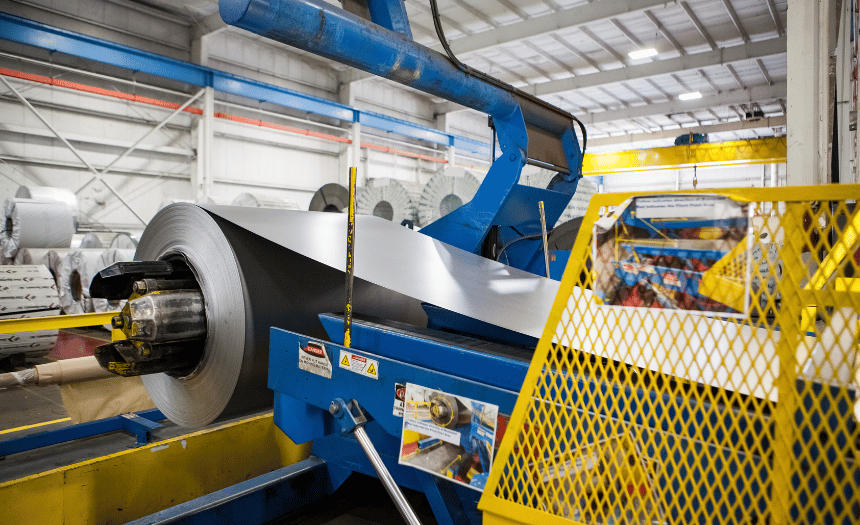

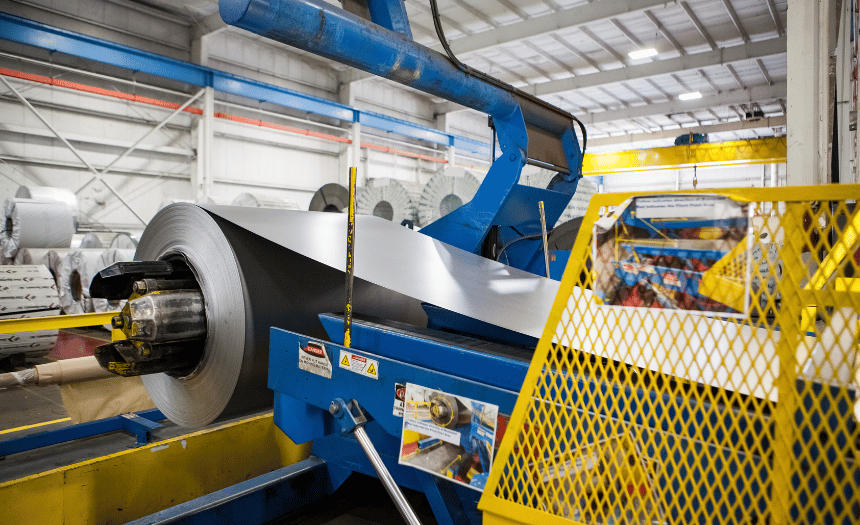

Aluminum blanking is a manufacturing process that uses a punch-and-die tool to cut flat sheets or large coils of aluminum into predefined shapes. After they are cut from the original sheet, these shapes are called blanks. Metal blanks serve as the raw material, or input for the production of various automotive components, including body panels, brackets, reinforcements, and heat shields.

Any kind of flat rolled metal can be blanked, including carbon steel, copper, stainless steel, and aluminum. With its strength, corrosion resistance and malleability, however, aluminum has become a preferred choice for automakers, and blanking enables the precise fabrication of the industry’s critical components. Thus, the blanking of aluminum is becoming more commonplace.

Aluminum holds immense importance for the automotive industry. According to the 2023 North American Light Vehicle Aluminum Content and Outlook, aluminum’s market share will increase by nearly 100 net pounds per vehicle between 2020 and 2030. The lightweight nature of aluminum offers significant advantages in terms of fuel efficiency, vehicle handling, and emissions reduction.

Blanking allows for efficient mass production, meeting the industry’s high volume demands while maintaining precision and dimensional accuracy.

Blanked aluminum serves as a fundamental building block for a wide range of automotive products such as doors, hoods, fenders, radiators, suspension, and structural components. The accuracy and consistency achieved through aluminum blanking contribute to the overall quality, shape, and performance of these components.

The Aluminum Association has organized hundreds of aluminum alloys into various grades and assigned each grade a four-digit identifier. The first digit refers to the alloy’s class. Each class represents a different alloy. For example, the 1xxx series is pure aluminum. The 3xxx series is a mix of aluminum, manganese, and copper. And the 6xxx series is a mix of aluminum, manganese, and silicon.

Virtually all aluminum grades can undergo blanking, depending on the specific requirements of the automotive industry. Frequently used grades in automotive include 1100, 2024, 3003, 3004, 3105, 4032, 5005, 5052, 5083, 5182, 5251, 5754, 6016, 6022, 6061, 6181, 7003, and 7046. These grades possess unique characteristics, such as excellent formability, corrosion resistance, and structural integrity, making them ideal for automotive applications.

The widths and thicknesses processed by aluminum blanking van vary depending on the specific part requirements of automotive manufacturers. Typical widths range from a few inches to several feet, while thicknesses can range from thin gauges (e.g., 0.010 inches) to thicker gauges (e.g., 0.250 inches). The precise dimensions are determined by the desired final product and its structural requirements.

It’s important to note that these are general guidelines, and the specific thickness requirements for aluminum blanking will depend on the part specifications and the capabilities of the metal fabrication company.

Multi-blanking is the process of feeding a large coil of flat rolled sheet into a shear or press that is timed with the feed of the line. Blanks are continuously stamped as the coil unwinds and pays in to the cutting station. Multi-blanking offers many benefits for the automotive industry, especially since it such a high volume market. Multi-blanking enables the efficient processing of coils, with improved consistency and reduced handling and reducing downtime between setups. Multi-blanking is possible with nearly any size coil, but works best with large coils up to 35,000 lbs.

Aluminum blanking is a crucial process, and it’s essential to differentiate the different types of blanking processes and nomenclature.

Aluminum is the fastest-growing automotive material, rising from 340 lbs per vehicle in 2010 to 459 lbs per vehicle in 2020. With the increased interest in fuel economy and lightweight, aluminum’s use by the industry is expected to continue to grow.

Aluminum blanking plays a pivotal role in the automotive industry, enabling the precise fabrication of vital aluminum components that contribute to vehicle performance, fuel efficiency, and lightweight design. As the automotive sector continues to evolve, the demand for high-quality blanked aluminum will only increase.

By understanding the nuances of aluminum blanking and partnering with an experienced first-stage aluminum blanking company, automotive manufacturers can achieve exceptional results and maintain a competitive edge in this dynamic industry.

Kloeckner Metals is a full-line aluminum supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and highly innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: