Kloeckner Metals supplies a range of high strength dual phase steel grades to the automotive industry.

This grade is one of the most popular dual phase steels. It shows yield and tensile strengths at 330-430 MPa and 590-700 MPa, respectively. It can be found in auto floor paneling, outer hood, body sides, cowls, structural reinforcements, and fenders. It also goes by DP600.

This grade demonstrates a yield strength of 440-550 MPa and a tensile strength of 780-900 MPa. It is among the intermediate DP steels which are frequently used in auto body structures that require high energy absorption. This includes front and rear railing and reinforcement structure. Low yield strength, high work hardening rate, and excellent ductility allow for greater deformation energy absorption than conventional steels. It also goes by DP800.

This dual phase steel grade, also referred to as DP1000, demonstrates a yield strength of 590-740 MPa and a tensile strength of 980-1130 MPa.

This grade is one of the newest technologies in dual phase steel. Its extreme high strength and adequate formability lend itself well to applications that rely on high yield strength to prevent intrusion into vehicle passenger compartments when there is a collision.

Similar to DP1180, this extremely high strength dual phase steel is best used for passenger safety cage components. This includes rockers, pillars, pillar reinforcements, roof rails, and cross members.

This grade is one of the most popular dual phase steels. It shows yield and tensile strengths at 330-430 MPa and 590-700 MPa, respectively. It can be found in auto floor paneling, outer hood, body sides, cowls, structural reinforcements, and fenders. It also goes by DP600.

This grade demonstrates a yield strength of 440-550 MPa and a tensile strength of 780-900 MPa. It is among the intermediate DP steels which are frequently used in auto body structures that require high energy absorption. This includes front and rear railing and reinforcement structure. Low yield strength, high work hardening rate, and excellent ductility allow for greater deformation energy absorption than conventional steels. It also goes by DP800.

This dual phase steel grade, also referred to as DP1000, demonstrates a yield strength of 590-740 MPa and a tensile strength of 980-1130 MPa.

This grade is one of the newest technologies in dual phase steel. Its extreme high strength and adequate formability lend itself well to applications that rely on high yield strength to prevent intrusion into vehicle passenger compartments when there is a collision.

Similar to DP1180, this extremely high strength dual phase steel is best used for passenger safety cage components. This includes rockers, pillars, pillar reinforcements, roof rails, and cross members.

Dual Phase (DP) steels are available in different strength grades and are part of the Advanced High Strength Steel (AHSS) family. Their unique process, which requires producing martensitic properties that enhance strength, requires controlled chemistry, controlled cooling, and rigid process controls that will alter the microstructure to the material’s desired ferrite and martensite balance. DP steels have been a critical fixture in the automotive industry because they provide tensile strength and ductile properties, as well as good formability and dent resistance. In fact, they are considered the fastest growing type of AHSS used in automotive applications. DP steel grades are characterized by their specific tensile strength.

ANSWER:

This grade is composed of .1% carbon, .1% manganese, and .3% silicon.

ANSWER:

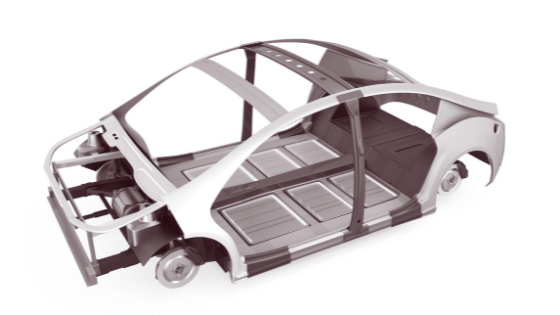

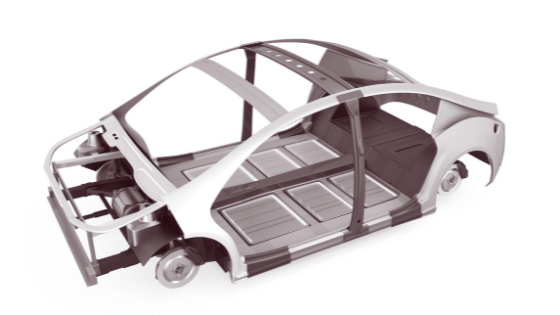

There are countless reasons why AHSS and specifically DP steels are so popular in the automotive industry. For one, AHSS steels have more elongation at equivalent strength, which equates to better formability. They are processed differently than conventional steels, as their microstructure adapts during phase transformations to adopt a two phase steel with both ferritic and martensitic structures. In vehicle application this amounts to lightweight components that are stronger than conventional steels, strong enough to demonstrate superior crash test safety requirements. Lower and intermediate DP grades can be used for complex geometry and extreme strength grades can be used for passenger safety cage components.

ANSWER:

DP steel consists of a precise mixture of ferrite and martensite that provide strength and ductility. While most sheet steel mills have the necessary equipment and process capabilities to produce high strength low alloy steels, only certain mills are equipped to produce DP steels due to the tight control processing required to achieve them.

ANSWER:

Many DP applications will be found in the automotive industry for everything from rails, paneling, and flooring to passenger safety cage components.

ANSWER:

The grades of DP steels are characterized by their tensile strength. They range from TS 590 MPa to 1200 MPa.

ANSWER:

This grade is composed of .1% carbon, .1% manganese, and .3% silicon.

ANSWER:

There are countless reasons why AHSS and specifically DP steels are so popular in the automotive industry. For one, AHSS steels have more elongation at equivalent strength, which equates to better formability. They are processed differently than conventional steels, as their microstructure adapts during phase transformations to adopt a two phase steel with both ferritic and martensitic structures. In vehicle application this amounts to lightweight components that are stronger than conventional steels, strong enough to demonstrate superior crash test safety requirements. Lower and intermediate DP grades can be used for complex geometry and extreme strength grades can be used for passenger safety cage components.

ANSWER:

DP steel consists of a precise mixture of ferrite and martensite that provide strength and ductility. While most sheet steel mills have the necessary equipment and process capabilities to produce high strength low alloy steels, only certain mills are equipped to produce DP steels due to the tight control processing required to achieve them.

ANSWER:

Many DP applications will be found in the automotive industry for everything from rails, paneling, and flooring to passenger safety cage components.

ANSWER:

The grades of DP steels are characterized by their tensile strength. They range from TS 590 MPa to 1200 MPa.

Between our global footprint, international transportation network,...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: