Kloeckner Metals supplies advanced and ultra high strength steel to the North American automotive industry.

| Grades | ||||

|---|---|---|---|---|

| DP590 | ||||

| DP790 | ||||

| DP980 | ||||

| DP1180 | ||||

| DP1270 | ||||

| Grades | ||||

|---|---|---|---|---|

| MS1300 | ||||

| MS1500 | ||||

| MS1700 | ||||

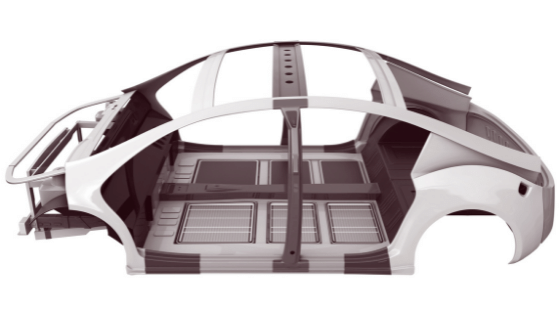

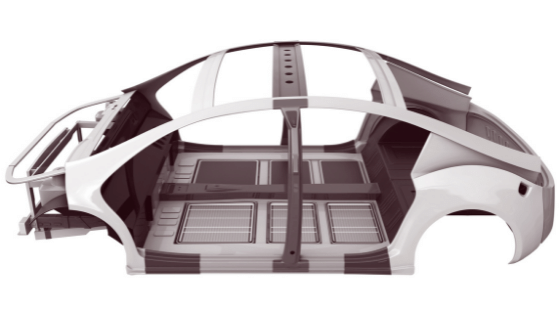

AHSS and UHSS are uniquely engineered innovative materials for the automotive industry demonstrating superior strength-to-weight ratios. Complex chemical compositions and precise strengthening techniques are applied to achieve the particular ductility, strength, toughness, fatigue resistance and other properties necessary in vehicle manufacturing.

The AHSS/UHSS steel family includes dual phase (DP) and martensitic steel, among others. Dual phase and martensitic steels are designated by yield strength of the material after forming and vehicle strength. For DP steels this ranges from 300 to 1300 MPa. Martensitic steels tend to show higher strengths up to 1700 MPa. Both of these steel grades are utilized in vehicle components from panels to passenger safety compartments.

ANSWER:

Yes. Advanced & ultra high strength steels are ideal for vehicle frame and crash structures. These complex and sophisticated steels are precisely produced to satisfy automotive safety guidelines. AHSS and UHSS steel plate is lightweight and affordable, yet able to meet strict safety, emissions, and performance standards, according to World Steel Auto.

ANSWER:

These steel grades demonstrate the strength and ductility required for use in the automotive industry. They reduce the overall weight of a vehicle by enabling improved geometry and decreasing material thickness.

ANSWER:

Third generation AHSS steels are the most current development by materials engineers to achieve the ultra high strength and ductility expressed in previous steels while improving on the problems associated with them.

Dual-phase (DP), transformation-induced plasticity (TRIP), and martensitic steels, all emerged from first generation high strength low alloy steels.

Twinning-induced plasticity (TWIP) steels and austenitic stainless steels emerged from second generation steels. They dramatically improved strength and elongation characteristics. However, high costs and joining challenges prohibited them from mainstream use in the auto industry.

ANSWER:

Yes. Advanced & ultra high strength steels are ideal for vehicle frame and crash structures. These complex and sophisticated steels are precisely produced to satisfy automotive safety guidelines. AHSS and UHSS steel plate is lightweight and affordable, yet able to meet strict safety, emissions, and performance standards, according to World Steel Auto.

ANSWER:

These steel grades demonstrate the strength and ductility required for use in the automotive industry. They reduce the overall weight of a vehicle by enabling improved geometry and decreasing material thickness.

ANSWER:

Third generation AHSS steels are the most current development by materials engineers to achieve the ultra high strength and ductility expressed in previous steels while improving on the problems associated with them.

Dual-phase (DP), transformation-induced plasticity (TRIP), and martensitic steels, all emerged from first generation high strength low alloy steels.

Twinning-induced plasticity (TWIP) steels and austenitic stainless steels emerged from second generation steels. They dramatically improved strength and elongation characteristics. However, high costs and joining challenges prohibited them from mainstream use in the auto industry.

Between our global footprint, international transportation network,...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: