Considering using galvanized steel pipe in your next project?

It’s a good choice for many tasks thanks to its reliability, strength, affordability, and corrosion resistance. That’s why most home improvement projects and industrial applications use galvanized steel pipe schedule 40.

Before you buy, though, it’s a good idea to find out more about galvanized steel pipe. We’ve compiled everything you need to know.

Kloeckner Metals is a full-line steel pipe and tube supplier and service center. Download our steel pipe and steel tube spec sheet and check what Kloeckner Metals routinely stocks.

Galvanized steel pipe has been dipped in molten zinc to help protect against corrosion. That layer of zinc protects the underlying metal from the weakening effects of weather and helps prolong the pipe’s longevity.

Incidentally, the word “galvanization” is a tribute to the 18th-century physicist Luigi Galvani who experimented with tiny electrical currents. When later scientists realized you could coat iron with a protective zinc layer through an electrochemical process, they called it galvanization in Galvani’s honor.

Grime, chemicals, moisture, or salt can corrode metal. Corrosion occurs when the atoms in the surface of the metal oxide or lose oxygen ions to the corroding element. Most metals oxidize easily to oxygen-rich environments such as air or water.

By galvanizing steel, metal manufacturers prevent those corroding substances from reaching the metal underneath the zinc. Instead of the steel corroding, the zinc corrodes. Sometimes, an element called chromate is added to the zinc, which oxidizes the zinc faster. This is called sacrificial protection.

Many different grades of steel can be galvanized. A53 steel pipe and A595 steel pipe are two of the mostly common grades.

But cast steel, hot-rolled steel, cold-rolled steel, and even some grades of stainless steel all qualify for galvanization. In general, the presence of iron in any metal makes it a candidate for a protective zinc coating.

The difference among galvanized steel grades typically lies in how they were coated. For instance, a zinc-iron alloy actually composes 50%-70% of the coating for most hot-rolled steels. A thin layer of unalloyed zinc goes on top of that. Click the link to learn more about Kloeckner Metals’ hot dip galvanizing and galvanization capabilities, and how the process benefits customers.

Galvanized steel pipe comes in a variety of dimensions and sizes. When you buy it, you’ll want to measure its diameter by nominal size. To find nominal size, measure the inside diameter of the pipe. Most nominal pipe sizes run between ¼ and 2 ½ inches.

If you do not have access to a cut end to measure inside the pipe, you can estimate the nominal size of a pipe by measuring its outside. Keep in mind, however, that you’ll have to account for wall size, which may be different from pipe to pipe.

The rule of thumb says to measure the outer circumference and divide by pi (3.14). If you have a standard pipe, subtract ¼ inch for the wall. For an extra strong pipe, subtract ⅜ inch.

For reference, 2 in. x 10 ft. is a very common size for this product.

The chemical composition matters because the metal has to bond at a chemical level with the zinc alloy that coats it. If a steel pipe has a silicon content above 0.25%, it will cause the zinc-alloy layer to grow very fast and eventually consume the unadulterated layer of zinc.

In general, galvanized steel should have a carbon content of less than 0.25%, phosphorus of less than 0.05%, and manganese of less than 1.3%. Silicon should run between 0% and 0.25%.

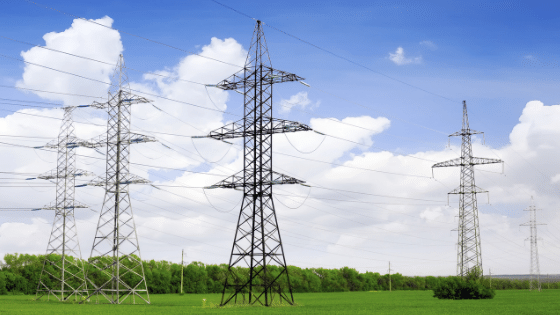

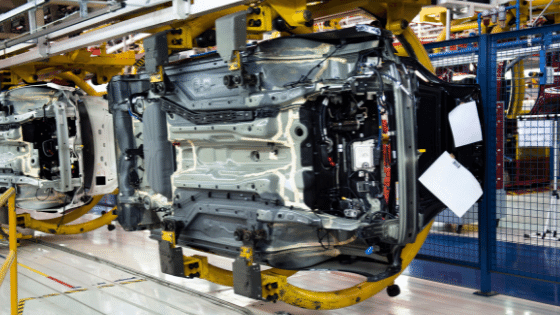

Due to its affordable cost and reliable strength, many industries employ galvanized steel pipe. The agriculture, automotive, aerospace, manufacturing, power transmission, heavy trucks and transportation, wind and solar and electrical utilities industries all use galvanized steel.

Galvanized steel is best known for its use in construction and automobile manufacturing.

Buildings created with galvanized steel can last 50 years without needing maintenance. Stainless steel and structural steel won’t do that.

New galvanized pipe looks nickel colored. It may also feature a marbled appearance. Over time, though, the pipe tends to grow duller. While the protective zinc layer can greatly extend the metal’s useful lifespan, galvanized steel will corrode after about 40-50 years in use.

If you notice rust, it’s definitely time to look for new pipes. When purchasing galvanized steel — or any fabricated metal product, for that matter — always inquire about the quality of the material, its tensile strength, corrosion resistance, and flexibility of use.

If you plan on cutting galvanized steel pipe, you will need a hacksaw, a tube-cutting tool, or a reciprocating saw. You may need multiple cutting devices if you have several sizes of pipe.

Secure the pipe in a vise or clamp, and support the longer end if necessary. Start cutting. Since you have no motor, you’ll need a lot of time and energy to cut this way, but it can be done. That said, don’t use too much pressure. Once the steel separates, file down the cut ends.

When you start cutting, you’ll need to rotate your cutter around the pipe several times. Once the cut is made, ream the pipe to avoid leaving burred ends. To do this, you’ll need a tool called a reamer.

This motorized cutting tool gets the job done fast. Put on your PPE, mark your cut, clamp your pipe down, and let that wheel do its work. Just make sure you don’t start with the wheel pressed directly against the pipe as this can cause it to snag on the pipe and damage the blade.

Painting galvanized steel pipe isn’t easy. The paint does not readily adhere to the zinc coating. One solution is to clean the pipe thoroughly, then rub it down with white vinegar. The vinegar interacts with the metal and makes it more adhesive for paint.

If you start painting galvanized steel pipe, do not use alkyd-based paints or oil-based primers. Instead, go with a primer and an acrylic latex paint.

Should you go with galvanized steel pipe?

It’s often a great choice. Although it’s one of the oldest modern construction materials, galvanized steel remains immensely popular. It’s strong, durable, and affordable. Contact us to learn more about what kind of steel is right for your commercial project.

Kloeckner Metals is a full-line steel pipe and steel tube supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and most innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: