5052 aluminum is popular because it is one of the most versatile aluminum alloys. It is strong enough for fuel tanks, but adaptable enough for utensils. Why is 5052 such a popular choice with our customers? Here’s the in-depth answer.

Among 5052 aluminum’s benefits are good weldability, very good resistance to corrosion, and high fatigue strength. Because the benefits are so varied, you see 5052 in a range of applications: it shows up in marine environments because of its resistance to corrosion, in architecture exposed to high vibration because of its high fatigue strength, and in pressure vessels and containers because of its good weldability.

Kloeckner Metals is a full-line aluminum supplier and service center. Download our aluminum spec sheet and check what Kloeckner Metals routinely stocks.

But the benefits don’t stop there. Aluminum 5052 also happens to be the strongest non-heat-treatable sheet and plate in common use. 5052 isn’t just easily welded and highly corrosion-resistant, it is also tough and strong. It has good drawing properties and a high rate of work hardening. Its overall versatility, not to mention excellent value, makes it one of the most serviceable alloys available.

Along with a few other 5000 series alloys, 5052 is corrosion resistant against seawater and salt spray. Its corrosion resistance means it can be used for large marine structures that are sensitive to failure, like the tanks of natural gas tankers. This is why you see 5052 aluminum on boats in general.

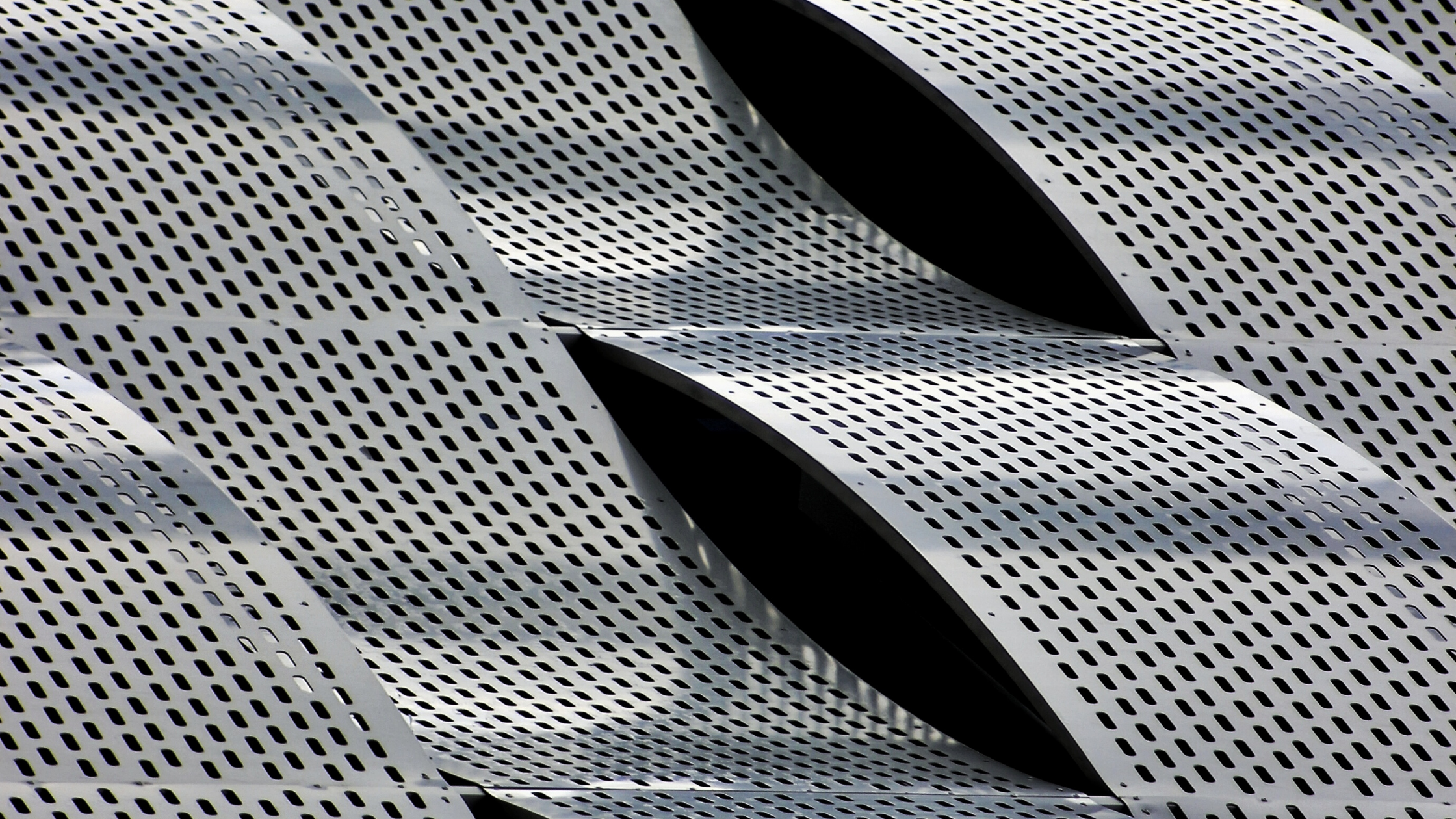

You’ll frequently see 5052 alloy in architectural facades.

You often see 5052 alloy aluminum in kitchen cabinets, appliances, fans and fan blades, home freezers, clock plates, fencing, and more.

5052 alloy aluminum has made its way into aircraft, bus, and truck manufacturing, road and name signs, fuel lines and tanks, streetlights, and other hallmarks of the transportation industry.

5052 aluminum is frequently used for general sheet metal work, heat exchangers, flooring panels, rivets and wires, chemical drums and other equipment, pressure vessels, treadplate, containers, and more.

In general, the strength of metal is measured by factoring both yield strength and tensile strength together. While yield strength considers the strength of the metal’s shape by measuring the point at which it deforms, tensile strength (or ultimate strength) measures how much a metal will stretch before it breaks. The strength of 5052 also depends on temper. See the following chart for a breakdown of the strength of the alloy.

| Strength Psi | Elongation % |

|

|||

| Alloy & Temper | Ultimate | Yield Set 0.2% | 1/16” | ½” | Brinell Hardness |

| 5052-0 | 28,000 | 13,000 | 25 | 30 | 47 |

| 5052-H32 | 33,000 | 28,000 | 12 | 18 | 60 |

| 5052-H34 | 38,000 | 31,000 | 10 | 14 | 68 |

| 5052-H36 | 40,000 | 35,000 | 8 | 10 | 73 |

| 5052-H38 | 42,000 | 37,000 | 7 | 8 | 77 |

Note: The Above properties are typical. For min/max data by temper refer to Aluminum Standards and Data from the Aluminum Association.

A key distinction of 5052 aluminum is that it is a non-heat treatable alloy, meaning that it is strengthened through cold working or strain-hardening, for example rolling or forging. The degree of strain hardening is indicated by temper designations. For example, H12 and H18 tempers represent one-quarter hard and full hard, respectively.

5052, like other non-heat-treatable alloys, contains alloying constituents that remain substantially in solid solution or are insoluble at all temperatures. Other non-heat-treatable alloys with high purity aluminum can be found in the 1,000, 3,000, and 5,000 series.

Strain-hardened material is returned to the full soft condition by heating above the annealing point with controlled cooling. Partial annealing, accompanied by some loss of strength will occur at 300-400°F.

Aluminum alloy 5052 is a good candidate for bending. While the elongation isn’t as high as the 3003 aluminum alloy, you still see a big difference between yield and tensile strength. And you will see high strength compared to other non-heat-treatable grades, not to mention 5052’s excellent corrosion resistance. Once you anneal 5052 aluminum, you can beat even the 3003 alloy when it comes to affordability.

5052 aluminum is part of the 5000 series of aluminum. Grades in this family are alloyed using 2.5% magnesium and .25% chromium. Here is a full breakdown of 5052 aluminum’s chemical composition.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

| 5052 | 0.45 Si/Fe | 0.0 | 0.1 | 0.1 | 2.2/2.8 | 0.15/0.35 | 0.1 | 0.0 |

Kloeckner Metals also stock 6061 aluminum and, as one of the most common grades of aluminum sheet, we frequently get asked about the difference between 5052 and 6061 aluminum. The main difference between 5052 and 6061 aluminum is that 6061 is a heat-treatable alloy and therefore stronger than 5052 aluminum. 6061 also features high resistance to stress combined with good formability and weldability. Because of its higher strength and lower formability, you see 6061 in more structural and engineering applications. Depending on your needs, we may recommend 6061 aluminum to you.

Kloeckner Metals is a full-line aluminum supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and most innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: