What is aluminum used for when it comes to the automotive industry? The short answer is, a lot! Aluminum is rapidly becoming a material central to vehicle manufacturing. In fact, aluminum is considered the fastest growing automotive manufacturing material. Looking ahead, it’s certain that demand for aluminum in the auto industry will continue driving upwards.

There are a few main reasons for this. Automobiles and the transportation industry at large are increasingly being targeted for improvements in carbon monoxide and other greenhouse gas emissions that contribute to smog and environmental issues. In the coming years, the push for sustainable and more eco-friendly vehicles is expected to see more incentives by policy makers with the goal of more efficient fuel economy and lower emissions.

The technological advancements that push the needle on performance metrics are inherently tied to base material attributes. Aluminum is a base metal with several key advantages. It is a versatile material with excellent corrosion resistance and the ability to be alloyed with a range of elements that optimize other specific mechanical properties, like electrical conductivity, formability, and impact resistance. However, above and beyond the key advantage aluminum brings to the auto industry is its high strength-to-weight ratio.

Kloeckner Metals is a full-line automotive aluminum supplier and service center. Download our aluminum spec sheet to view what Kloeckner Metals routinely stocks.

Because aluminum exhibits both strength and durability, it is able to meet the demands placed on the industry to meet sustainability goals without compromising on safety and performance. It is essential that electric cars compete in terms of their performance with gas-powered vehicles, while meeting or exceeding the same safety standards.

Electric cars have become a central investment in the future of automotive. However, they present a particular challenge to the industry, as batteries are both heavy and fall short of meeting range capacity equivalent to gas powered vehicles. Therefore, a light and durable material was needed to supplement the use of steel, which is a much denser metal.

Aluminum has proven the perfect manufacturing material to meet these challenges. Further optimizing on its lightweight nature, the affinity for alloy bonding has led to new developments in alloys specific for the needs of the auto industry.

The Aluminum Association describes how aluminum has been used in the auto industry since the dawn of the 20th century. At the time, it was used exclusively for auto bodies. Aluminum’s drawing characteristics and formability made it easy to work and shape. However, at this time, aluminum was not ideal for mass production due to manufacturing costs and limited production.

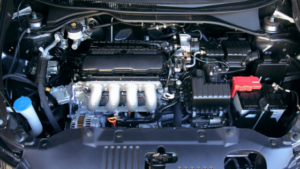

In 1961, the use of alloys in cars expanded. Production had increased and it was becoming a more affordable material. A breakthrough occurred which no longer limited aluminum to be used in auto body paneling. V-8 engine blocks were engineered using aluminum by the British Land Rover company and eventually gained a foothold in other critical car components. This included wheels, transmission castings, cylinder heads, and suspension joints.

Today, it is a preferred material for auto bodies, which is as true today as it was when it was first utilized by the auto industry. As technology has advanced, things like welding aluminum have become easier and more efficient. This, along with elevated processing and fabrication techniques, and an expanding inventory of alloys, have made it possible for powertrain and entire vehicle structures.

Autos are complex machines. They have upwards of 25,000 parts and many of them can be made with aluminum. Part of the reason it can be used for such a spectacular range of applications is due to its capability to form alloys. The chemical and mechanical properties vary according to the alloy combination in question.

The main alloys for auto manufacturing include: 1100, 2024, 3003, 3004, 3105, 4032, 5005, 5052, 5083, 5182, 5251, 5754, 6016, 6061, 6181, 7003, and 7046.

Aluminum is available in various formats and tempers which further benefit its popularity in the auto industry. These formats include: aluminum sheet, aluminum plate, aluminum bar, and aluminum tube.

The best alloys for auto bodies demonstrate excellent corrosion resistance, surface finish capabilities, and workability. Some of the most popular alloy choices for these applications include: 3105, 5005, 5083, 5182, 6016, and 6181.

While aluminum has a lower electrical conductivity than copper, it has the advantage of being a lighter material. 1350 is the alloy most widely associated with electrical wiring.

1100, 3105, and 5052 can be used in auto interiors.

More complex parts and critical auto components require strength, fatigue resistance, and weldability. 2024, 4032, 5052, 5005, 5083, 6016, 6082, and 6111 are choice alloys for engine components and structural auto framework.

The wide range of aluminum alloys match the complex nature of vehicles from their exterior to their engines. Alloys exhibiting several advantageous qualities like strength, corrosion resistance, impact resistance, formability, weldability, and electrical conductivity service the safety and performance needs of the industry. Kloeckner metals is happy to further assist you in finding the right aluminum and format for your needs.

Kloeckner Metals is a full-line automotive aluminum supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and most innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: