Kloeckner Metals is proud to carry ARKU deslagging machines across many of our nationwide branches.

Answer:

Deslagging is a process used in the metals industry to remove slag from molten metal. Slag is a byproduct of the metal refining process, and it is formed when impurities in the raw material are burned off or oxidized. Slag is usually made up of a combination of metal oxides, along with other impurities, such as sulfur, phosphorus, and silicon.

During the refining process, the slag floats to the top of the molten metal and forms a layer on the surface. This layer must be removed to ensure that the final product meets the required specifications. Deslagging is the process of removing the slag layer from the surface of the molten metal, usually by skimming or using a mechanical scraper.

Deslagging can be a manual or automated process, depending on the size and complexity of the operation. In smaller-scale operations, deslagging is often done manually using a long-handled tool to remove the slag from the surface of the metal. In larger operations, automated deslagging equipment is used to remove the slag quickly and efficiently.

Deslagging is an important part of the metal refining process, as it ensures that the final product meets the required quality standards. It also helps to prevent slag buildup in the refining equipment, which can cause damage and reduce efficiency over time.

Answer:

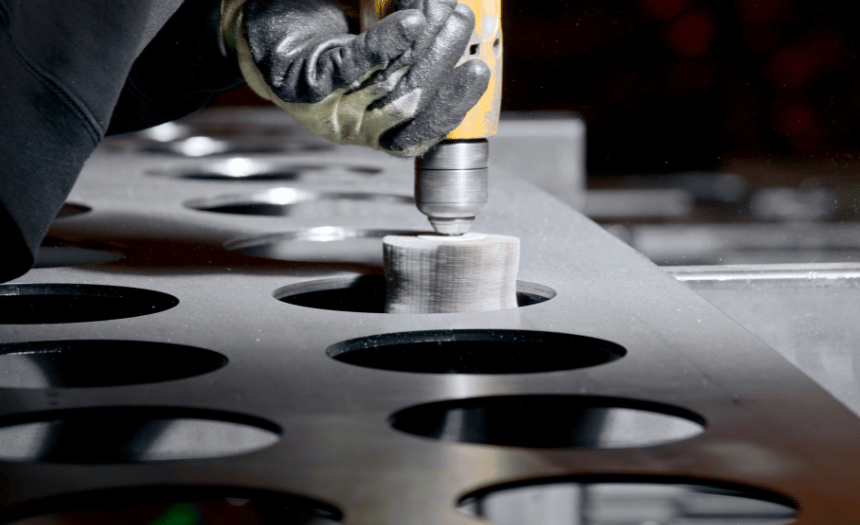

An ARKU deslagging machine is a type of automated equipment used in the metals industry for removing slag from the surface of molten metal. The ARKU deslagging machine is specifically designed to remove slag from the top of aluminum and zinc alloys, which are commonly used in industries such as automotive, aerospace, and construction.

The ARKU deslagging machine uses a mechanical scraper to remove the slag from the surface of the molten metal. The scraper is mounted on a robotic arm that is programmed to move over the surface of the metal and remove the slag in a controlled and precise manner. The machine is designed to operate at high speeds and can process large volumes of material quickly and efficiently.

One of the advantages of the ARKU deslagging machine is that it is fully automated, which means that it can operate continuously without the need for human intervention. This reduces the risk of accidents and improves overall safety in the workplace. The machine is also designed to be energy-efficient, which can help to reduce operating costs and improve sustainability.

Overall, the ARKU deslagging machine is a reliable and efficient piece of equipment that can help to improve productivity and quality in the metals industry. It is specifically designed for use with aluminum and zinc alloys, but similar deslagging machines are available for other types of metals as well.

Answer:

Deslagging is a process that can be used on a variety of metal types and forms, including plate, sheet, bar, angle, channel, beam, pipe, and tube. The specific metal types that are frequently deslagged depend on the industry and application, as well as the specific requirements of the final product.

For example, in the steel industry, both plate and sheet are commonly deslagged during the refining process to remove impurities and improve the quality of the final product. Similarly, bar, angle, channel, and beam may also be deslagged to improve the surface finish and remove any impurities that could compromise the integrity of the metal.

In the aluminum industry, sheet and plate are frequently deslagged to remove any impurities that could affect the surface finish or other properties of the final product. Pipe and tube may also be deslagged to improve the quality of the welds and reduce the risk of defects.

Overall, deslagging is a common process in the metals industry and is used on a variety of metal types and forms to improve the quality and performance of the final product. The specific metal types that are frequently deslagged depend on the industry, application, and specific requirements of the final product.

What is deslagging?

Answer:

Deslagging is a process used in the metals industry to remove slag from molten metal. Slag is a byproduct of the metal refining process, and it is formed when impurities in the raw material are burned off or oxidized. Slag is usually made up of a combination of metal oxides, along with other impurities, such as sulfur, phosphorus, and silicon.

During the refining process, the slag floats to the top of the molten metal and forms a layer on the surface. This layer must be removed to ensure that the final product meets the required specifications. Deslagging is the process of removing the slag layer from the surface of the molten metal, usually by skimming or using a mechanical scraper.

Deslagging can be a manual or automated process, depending on the size and complexity of the operation. In smaller-scale operations, deslagging is often done manually using a long-handled tool to remove the slag from the surface of the metal. In larger operations, automated deslagging equipment is used to remove the slag quickly and efficiently.

Deslagging is an important part of the metal refining process, as it ensures that the final product meets the required quality standards. It also helps to prevent slag buildup in the refining equipment, which can cause damage and reduce efficiency over time.

What is an ARKU deslagging machine?

Answer:

An ARKU deslagging machine is a type of automated equipment used in the metals industry for removing slag from the surface of molten metal. The ARKU deslagging machine is specifically designed to remove slag from the top of aluminum and zinc alloys, which are commonly used in industries such as automotive, aerospace, and construction.

The ARKU deslagging machine uses a mechanical scraper to remove the slag from the surface of the molten metal. The scraper is mounted on a robotic arm that is programmed to move over the surface of the metal and remove the slag in a controlled and precise manner. The machine is designed to operate at high speeds and can process large volumes of material quickly and efficiently.

One of the advantages of the ARKU deslagging machine is that it is fully automated, which means that it can operate continuously without the need for human intervention. This reduces the risk of accidents and improves overall safety in the workplace. The machine is also designed to be energy-efficient, which can help to reduce operating costs and improve sustainability.

Overall, the ARKU deslagging machine is a reliable and efficient piece of equipment that can help to improve productivity and quality in the metals industry. It is specifically designed for use with aluminum and zinc alloys, but similar deslagging machines are available for other types of metals as well.

What metal types can be deslagged?

Answer:

Deslagging is a process that can be used on a variety of metal types and forms, including plate, sheet, bar, angle, channel, beam, pipe, and tube. The specific metal types that are frequently deslagged depend on the industry and application, as well as the specific requirements of the final product.

For example, in the steel industry, both plate and sheet are commonly deslagged during the refining process to remove impurities and improve the quality of the final product. Similarly, bar, angle, channel, and beam may also be deslagged to improve the surface finish and remove any impurities that could compromise the integrity of the metal.

In the aluminum industry, sheet and plate are frequently deslagged to remove any impurities that could affect the surface finish or other properties of the final product. Pipe and tube may also be deslagged to improve the quality of the welds and reduce the risk of defects.

Overall, deslagging is a common process in the metals industry and is used on a variety of metal types and forms to improve the quality and performance of the final product. The specific metal types that are frequently deslagged depend on the industry, application, and specific requirements of the final product.

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: