Chances are, you have heard about aluminum extrusions. They have a major presence in a wide range of consumer and industrial goods. But what exactly are they, and what is the process like?

Extrusion is the process in which a solid piece of aluminum plate, tube, sheet or bar is forced by compression through a smaller die opening. The process has been likened to pushing a lump of Play-Doh through a mold or squeezing toothpaste through a tube. What starts out as an undefined mass takes on the shape of the form through which it’s pushed.

Kloeckner Metals is a full-line aluminum supplier and service center. Download our aluminum spec sheet and check what Kloeckner Metals routinely stocks.

Extruding aluminum beings with softening solid piece of metal with heat and then forcing it through a steel die. The end result is a die-opening shaped aluminum component that is corrosion-resistant, lightweight, and strong.

There are two standard methods of extruding aluminum:

During the extrusion process, the temperature of the entire walled container must remain constant.

According to the Aluminum Association, there are many factors in an extrusion process that influence how the final product will turn out, including:

These adjustable factors, coupled with inexpensive tooling, create near-limitless possibilities for design.

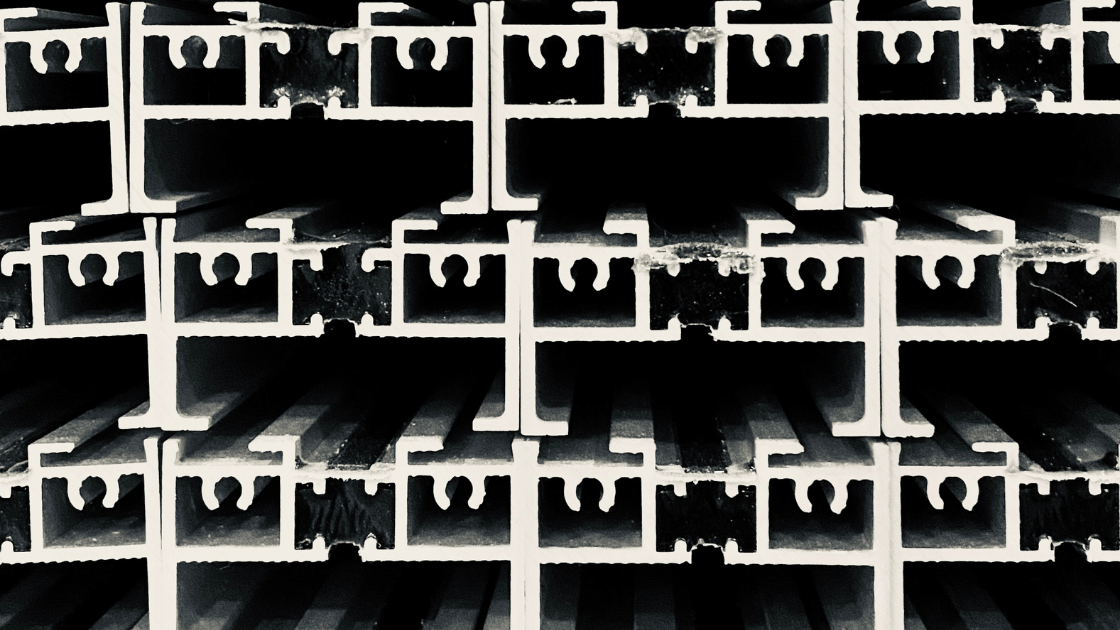

The extrusion process can create long components or smaller pieces ranging in size from one millimeter to several feet long. Because of aluminum’s light weight and malleable properties, extrusion shapes can be rather complex, including hollow and multiple chamber shapes.

The aluminum extrusion molding apparatus could be compared with a cake decorating kit. If you put the star tip on the pastry tube, you’ll get star-shaped frosting. If you place the flower shape on, you’ll get a flower pattern. The extrusion process is much the same. With the aid of powerful hydraulic presses, aluminum can be extruded into nearly any shape you can think of.

Here are a few standard aluminum extrusion shapes:

Yes! A custom die can be designed and created to best meet a customer’s needs. Custom aluminum extrusions can be fabricated with holes and other features to support the customer’s unique manufacturing process. The material is shaped according to the die’s opening, taking on its same profile.

Custom extrusions are compatible with a wide variety of aluminum grades and finishes. A major benefit of custom extrusions is that they can provide uniformity across an array of complex designs.

Obviously, you want to look for an aluminum extrusion company that is skilled and honest. You’ll want to consider your budget, project timeline, standard requirements, delivery preferences, and post-delivery support requirements.

Kloeckner Metals is a full-line aluminum supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and most innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: