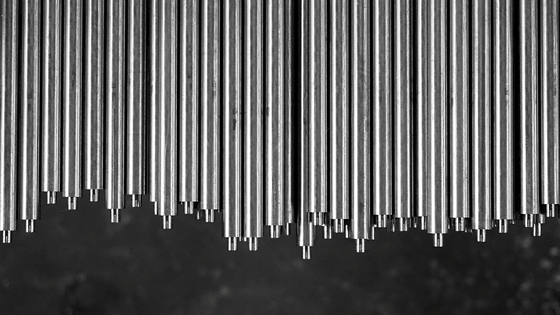

Kloeckner Metals stocks a variety of cold finished products including ATSM A108 Cold Finished Squares, Rounds, Hexagons, and Flats.

ASTM A108 steel is a medium carbon and alloy steel that has up to 39 grades that are defined by their chemical composition. This steel is typically cold finished, but it can also be cold drawn, cold rolled, ground, heat treated, hot wrought, polished, and turned.

ASTM A108 can be machined and welded, but it is not as suited to these processes as a lower carbon steel. A108 is more easily cracked than other steel because of its medium carbon content.

It is typically used in construction applications and in heavy machinery. Its high strength makes it suitable for parts in heavy machinery and in shafting. This steel is important for vehicle building and mechanical engineering as well.

Advantages:

Disadvantages:

ATSM A108 steel is typically used in the construction industry. Some grades of A108 are used for vehicle and machine engineering. This steel is used for parts that have a higher strength demand.

Typical applications for A108 include parts for heavy machinery and construction. Some applications include gears, drilling parts, and shafts. It can also be used to create parts for a car that need to be extra strong.

ATSM A108 steel is not as easily machinable as some other lower carbon steels. Its medium carbon content makes it more prone to cracking when compared to other steel. It is still possible, but it may be more difficult.

It is suitable for welding, but it is more difficult to weld when compared to low-carbon steel. The carbon content of steel is the determining factor of the steel’s weldability, and the higher the carbon content, the less easy it is to weld. A108 is medium carbon steel meaning it is harder to weld than lower carbon steel, but easier to weld than higher carbon steel.

A108 steel is often heat treated. This process makes the steel stronger than it already was, and many industries find this valuable for their specific applications.

Advantages:

Disadvantages:

ATSM A108 steel is typically used in the construction industry. Some grades of A108 are used for vehicle and machine engineering. This steel is used for parts that have a higher strength demand.

Typical applications for A108 include parts for heavy machinery and construction. Some applications include gears, drilling parts, and shafts. It can also be used to create parts for a car that need to be extra strong.

ATSM A108 steel is not as easily machinable as some other lower carbon steels. Its medium carbon content makes it more prone to cracking when compared to other steel. It is still possible, but it may be more difficult.

It is suitable for welding, but it is more difficult to weld when compared to low-carbon steel. The carbon content of steel is the determining factor of the steel’s weldability, and the higher the carbon content, the less easy it is to weld. A108 is medium carbon steel meaning it is harder to weld than lower carbon steel, but easier to weld than higher carbon steel.

A108 steel is often heat treated. This process makes the steel stronger than it already was, and many industries find this valuable for their specific applications.

ANSWER:

AISI 1018 steel is typically hot rolled while A108 steel is typically cold rolled. AISI 1018 steel has a lower carbon content than A108. A108 steel is heavier than 1018. 1018 has easier machinability and weldability because of its lower carbon content when compared to A108.

ANSWER:

A108M is the metric equivalent version of A108. This is the name used in countries that use the metric system instead of the imperial system. The USA and Liberia use the imperial system, while pretty much every other country uses the metric system.

Squares are solid rods of steel that have four sides and are shaped like a square. Rounds are solid rods of steel that are shaped like a circle. Hexagons are long, solid steel rods that have six sides and are shaped like a hexagon. Flats are long, thin strips of steel. They are flat-rolled steel cut into thin strips.

ANSWER:

AISI 1018 steel is typically hot rolled while A108 steel is typically cold rolled. AISI 1018 steel has a lower carbon content than A108. A108 steel is heavier than 1018. 1018 has easier machinability and weldability because of its lower carbon content when compared to A108.

ANSWER:

A108M is the metric equivalent version of A108. This is the name used in countries that use the metric system instead of the imperial system. The USA and Liberia use the imperial system, while pretty much every other country uses the metric system.

Squares are solid rods of steel that have four sides and are shaped like a square. Rounds are solid rods of steel that are shaped like a circle. Hexagons are long, solid steel rods that have six sides and are shaped like a hexagon. Flats are long, thin strips of steel. They are flat-rolled steel cut into thin strips.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: